Moisture content detecting, controlling and monitoring system

A detection system and content technology, applied in the field of terahertz detection, can solve problems such as low signal-to-noise ratio and stability, and can not meet market demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

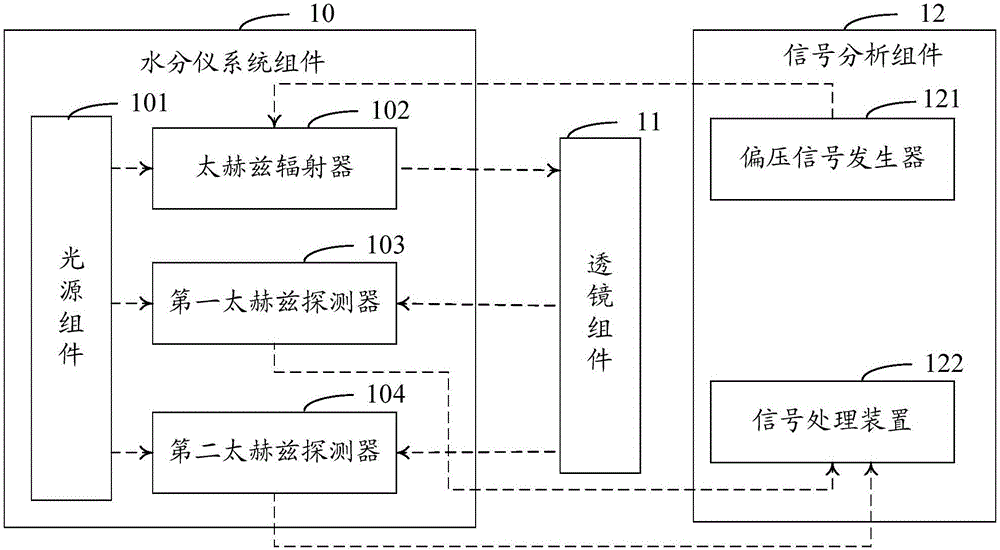

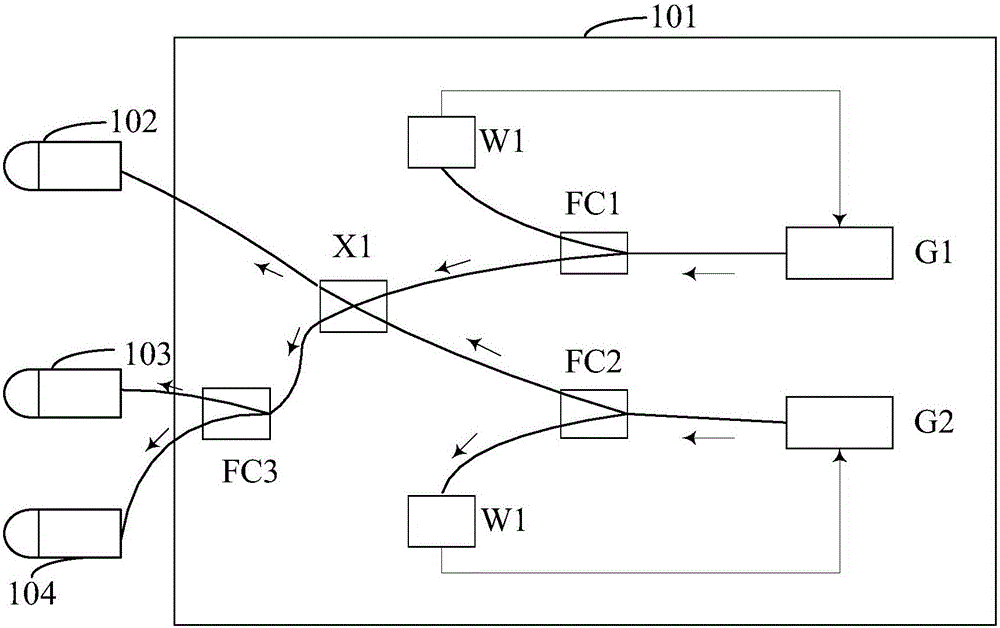

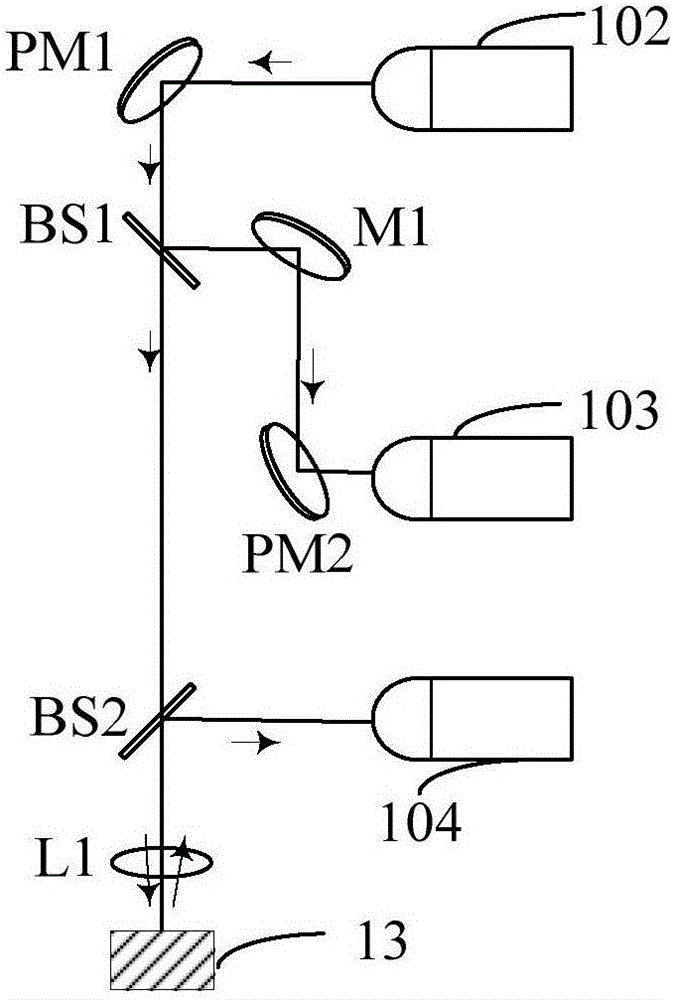

[0031] see figure 1 Shown is a schematic diagram of the composition and structure of the moisture content detection system in Embodiment 1 of the present invention. Such as figure 1 As shown, the moisture content detection system according to Embodiment 1 of the present invention includes a moisture meter system component 10, a lens component 11, and a signal analysis component 12. The moisture meter system component 10 includes a light source component 101 and terahertz radiation components respectively connected to the light source component 101. 102 , a first terahertz detector 103 and a second terahertz detector 104 , and the signal analysis component 12 includes a bias signal generator 121 and a signal processing device 122 .

[0032] The lens assembly 11 is arranged between the terahertz radiator 102, the first terahertz detector 103 and the second terahertz detector 104, the terahertz radiator 102 is connected to the bias signal generator 121; the first terahertz detec...

Embodiment 2

[0061] According to the moisture content detection system of the first embodiment above, the present invention also provides a moisture content control system. Such as Image 6As shown, the moisture content monitoring system of the second embodiment includes a microcomputer 21 and the moisture content detection system 20 of any one of the above-mentioned embodiments, the microcomputer 21 is connected with the signal processing device 201 of the moisture content detection system 20, and the microcomputer 21 can also be connected to the assembly line equipment22.

[0062] The signal processing device 201 is used to feed back the detected water content value of the sample to be tested to the microcomputer;

[0063] The microcomputer 21 is used to compare the moisture content value with the preset moisture content threshold value to obtain a comparison result, judge whether the sample to be tested needs to be further dehydrated according to the comparison result, and obtain a jud...

Embodiment 3

[0069] According to the moisture content detection system of the first embodiment above, the present invention also provides a moisture content monitoring system. Such as Figure 8 As shown, the moisture content monitoring system of the third embodiment includes a data storage server 31 and the moisture content detection system described in any one of the above embodiments, and the data storage server 31 is connected to the signal processing device 301 of the moisture content detection system 30 . Here, the data storage server 31 may be a cloud storage. The signal processing device 301 uploads the monitored moisture content values at various moments to the data storage server 31 in real time, and the storage server 31 can generate a real-time moisture content change curve based on the received moisture content values.

[0070] With the solution of this embodiment, the manager of the assembly line can use various terminal programs, such as computer software, mobile phone app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com