Quantitative determination method for phthalate plasticizer in dairy products

A quantitative detection method and phthalic acid technology, applied in the field of chemical detection, can solve the problems of complicated operation, high degree of professionalism and long detection time, and achieve the effect of simple and accurate operation and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

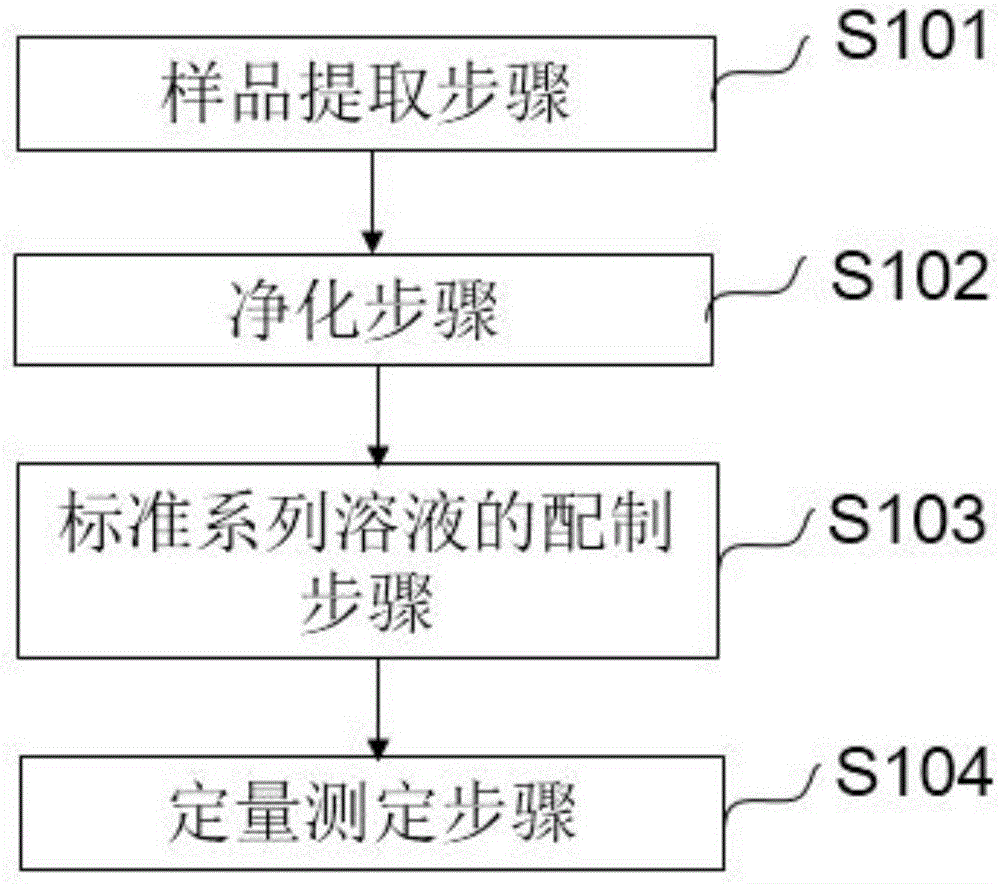

[0027] Sample extraction steps: Weigh 2 g of liquid dairy products that are uniformly mixed into a 10 mL test tube, add 2 mL of ethyl acetate and 4 mL of acetonitrile, and vortex for 1 min (if the sample is still not fully dissolved, perform ultrasonic mixing for 10 min). Centrifuge at 5000r / min for 10min, take the supernatant into another glass centrifuge tube, add sodium chloride until the aqueous phase is saturated, vortex and mix for 1min, let stand or centrifuge to separate layers, take the upper organic phase into another glass tube, Concentrate to nearly dryness by blowing nitrogen in a water bath at 40°C, and add 2 mL of n-hexane and a small amount of anhydrous sodium sulfate to obtain a solution to be purified.

[0028] Purification step: add 5mL acetone and 5mL n-hexane to activate the ProElut PSA GLASS column in turn, control the flow rate at about 1 drop per second, slowly add all the liquid to be purified, take 5mL n-hexane and 5mL 4% acetone-96% n-hexane mixture, ...

Embodiment 2

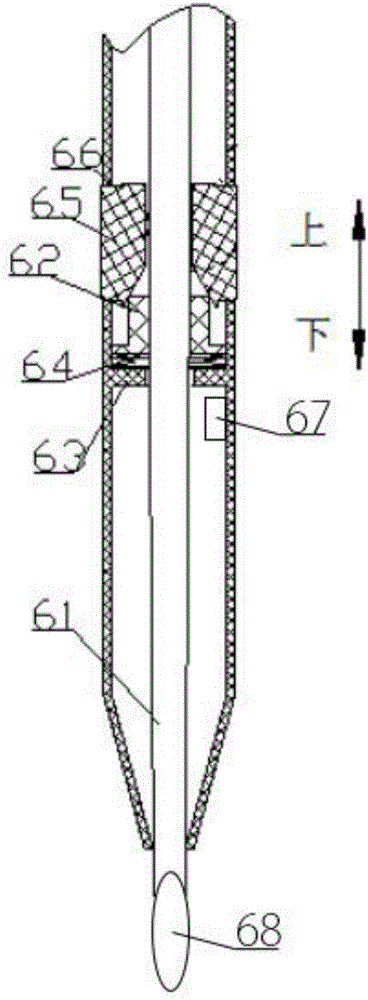

[0036] Such as figure 2 As shown, the aseptic pick-and-place device includes a sleeve 66 with an upper end and a lower end, an ultraviolet lamp 67 is disposed in the sleeve 66, and a sliding rod 61 capable of axially moving (ie, up and down) in the sleeve 66 . The lower end of the slide bar is provided with a medicine spoon 68, which can be inserted into the sleeve pipe 66, and the medicine spoon 68 can be sterilized by an ultraviolet lamp 67. In order for the sliding rod 61 to protrude from the sleeve 66 , an opening is provided at the lower end of the sleeve 66 .

[0037] Such as figure 2 As shown, the aseptic pick-and-place device 100 also includes a push rod mechanism. The push rod mechanism includes a slide block 62 fixedly sleeved on the slide rod 61 in the sleeve 66, an annular flange 63 provided on the inner wall of the sleeve 66, and an annular flange 63 disposed between the slide block 62 and the annular flange 63. A compression spring 64, and a radial pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com