Gas distribution and diffusion plate and plasma processor

A gas distribution and diffusion plate technology, used in semiconductor/solid-state device manufacturing, electrical components, discharge tubes, etc., can solve the problems of unstable wafer processing process, unstable surface temperature of gas distribution diffusion plate, etc., to improve quality and performance, ensuring stability, and improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

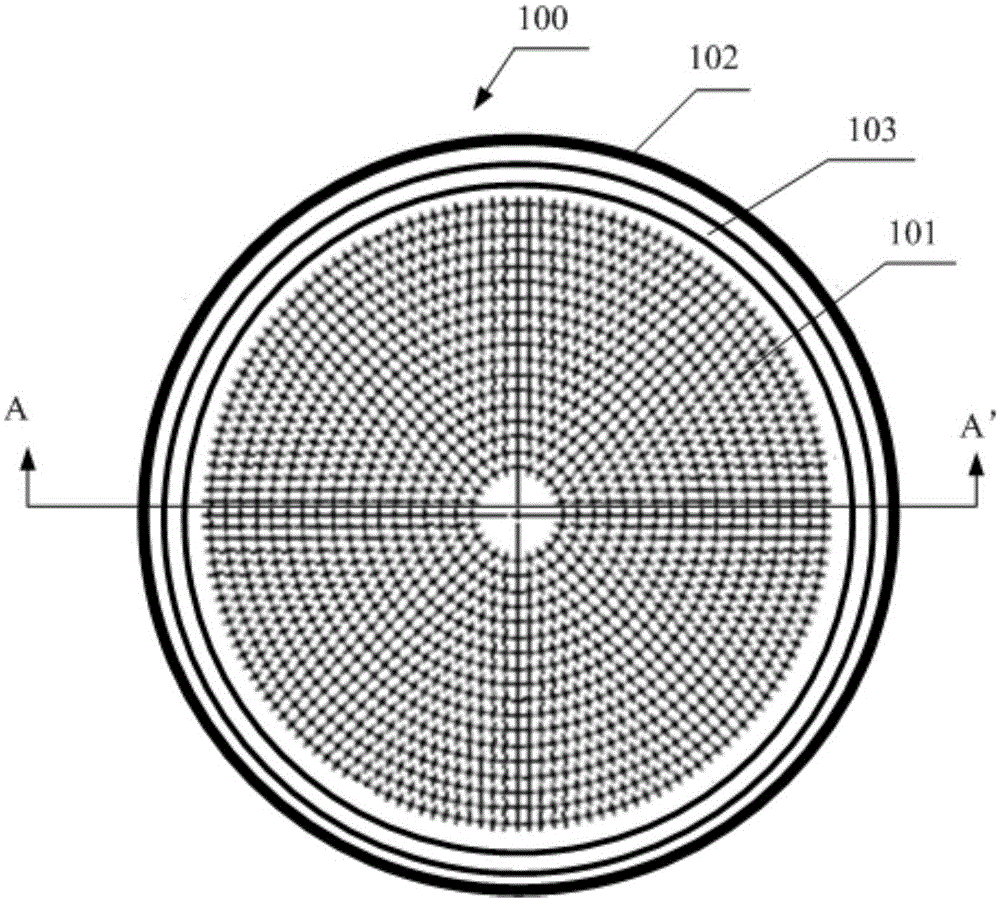

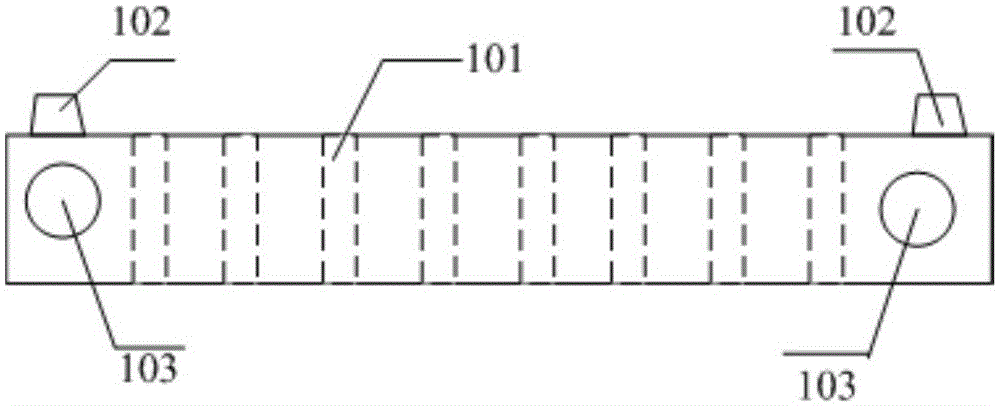

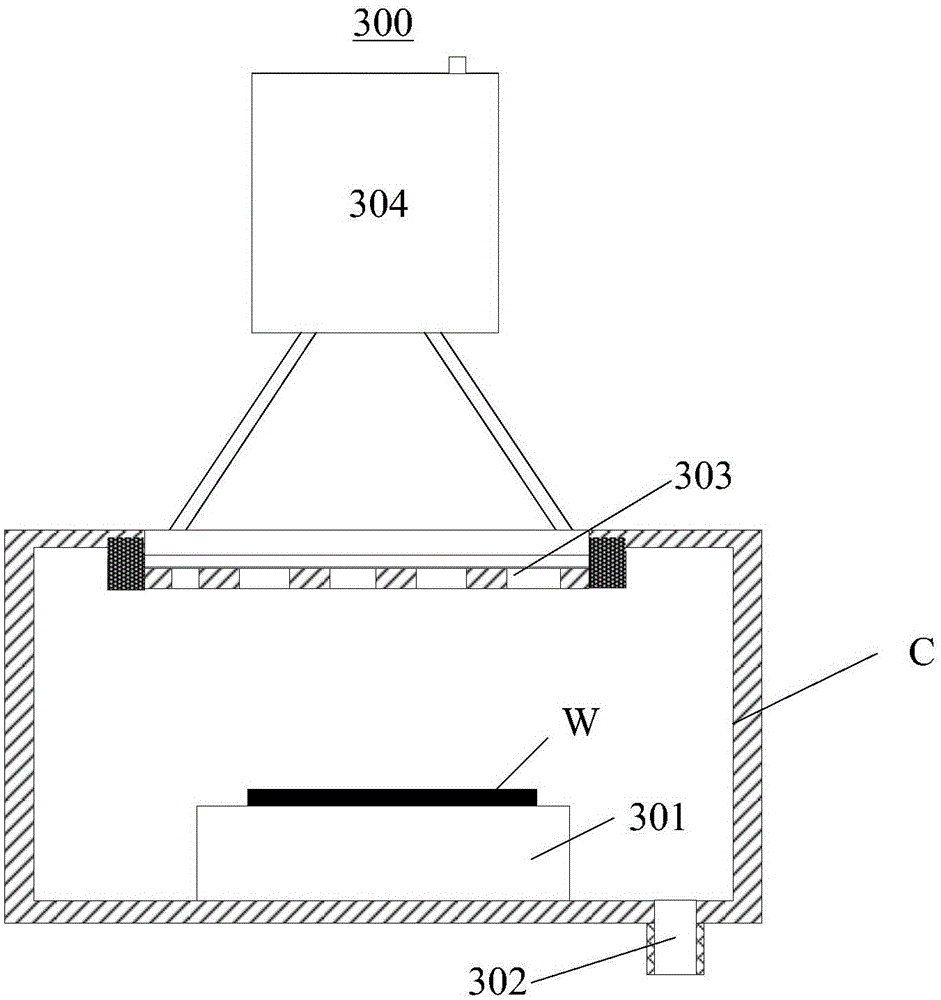

[0025] In order to make the purpose and technical effect of the present invention more clear and complete, the specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

[0026] The inventors found that, in the prior art, the gas distribution and diffusion plate used in the reaction chamber is usually formed from a whole metal plate, and there is no temperature measurement and temperature control device inside. In the reaction chamber, the factors affecting the surface temperature of the gas distribution diffuser mainly include: the heat of the wafer carrier used to heat the wafer at the bottom of the reaction chamber and the heat radiated from the plasma source at the top of the reaction chamber. However, during the entire process, from the time when the robot arm sends the wafer into the reaction chamber until the process ends and the wafer exits, the temperature on the surface of the gas distribution diffu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com