A kind of preparation method of phosphoric acid-doped layer-by-layer self-assembled polymer composite film

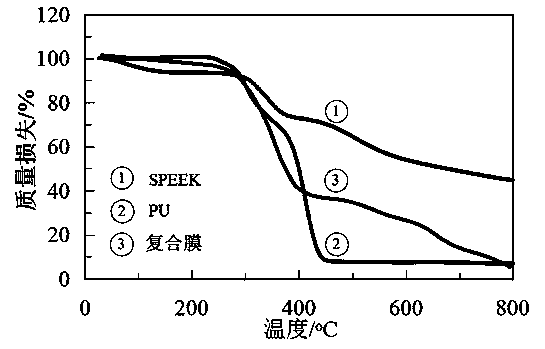

A layer-by-layer self-assembly and self-assembled membrane technology, applied in fuel cells, electrical components, electrochemical generators, etc., to achieve the effects of improving electrical conductivity, improving proton conductivity, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the phosphoric acid-doped layer-by-layer self-assembled polymer composite membrane of this embodiment is carried out according to the following steps:

[0028] (1) Add 76mL of deionized water to 2.35g of SPEEK with a sulfonation degree of 94.3%, at 70 o C carries out magnetic stirring, and the preparation volume fraction is the SPEEK homogeneous aqueous solution of 3%;

[0029] (2) Use piranha solution (300mL98% H 2 SO 4 , 100mL 30% H 2 o 2 ) The treated negatively charged glass sheet is put into the PU solution with a mass fraction of 3%, and soaked for 6 minutes;

[0030] (3) Take out the glass piece, soak it in deionized water for 20s, take it out and blow it until there is no water on the surface, soak it again in the SPEEK homogeneous aqueous solution in step (1), soak it for 6min, then soak it in deionized water for 20s, take it out and blow it out. Until the surface is dry, complete the self-assembly of PU and SPEEK, which is record...

Embodiment 2

[0036] The preparation method of the phosphoric acid-doped layer-by-layer self-assembled polymer composite membrane of this embodiment is carried out according to the following steps:

[0037] (1) Add 80 mL of deionized water to 0.81 g of SPEEK with a sulfonation degree of 94.3%, at 50 o C carries out magnetic stirring, and the preparation volume fraction is the SPEEK homogeneous aqueous solution of 1%;

[0038] (2) Use piranha solution (300mL98% H 2 SO 4 , 100mL 30% H 2 o 2 ) The treated negatively charged glass sheet is put into the PU solution with a mass fraction of 1%, and soaked for 6 minutes;

[0039] (3) Take out the glass piece, soak it in deionized water for 20s, take it out and blow it until there is no water on the surface, soak it again in the SPEEK homogeneous aqueous solution in step (1), soak it for 6min, then soak it in deionized water for 20s, take it out and blow it out. Until the surface is dry, complete the self-assembly of PU and SPEEK, which is reco...

Embodiment 3

[0044] The preparation method of the phosphoric acid-doped layer-by-layer self-assembled polymer composite membrane of this embodiment is carried out according to the following steps:

[0045] (1) Add 60 mL of deionized water to 3.16 g of SPEEK with a sulfonation degree of 45.3%, at 80 o C carries out magnetic stirring, and the preparation volume fraction is the SPEEK homogeneous aqueous solution of 5%;

[0046] (2) Use piranha solution (300mL98% H 2 SO 4 , 100mL 30% H 2 o 2 ) The treated negatively charged glass sheet is put into the PU solution with a mass fraction of 3%, and soaked for 6 minutes;

[0047] (3) Take out the glass piece, soak it in deionized water for 20s, take it out and blow it until there is no water on the surface, soak it again in the SPEEK homogeneous aqueous solution in step (1), soak it for 6min, then soak it in deionized water for 20s, take it out and blow it out. Until the surface is dry, complete the self-assembly of PU and SPEEK, which is reco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| Degree of sulfonation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com