Mixed gel food with good thermal stability and method for producing the same

A technology of mixed gel and gel food, applied in the manufacture of the mixed gel food and the field of mixed gel food, can solve the problems of low melting temperature of gel, easy melting of jelly, difficult gel modeling, etc. Market application prospects, long shelf life at room temperature, and the effect of good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The manufacture of embodiment 1 mixed gel food

[0026] The mixed gel food of the present embodiment is manufactured based on the following formula:

[0027] White sugar 20wt%, purified konjac gum 0.15wt%, Kappa type carrageenan 0.3wt%, low acyl gellan gum 0.2wt%, xanthan gum 0.07wt%, potassium citrate 0.1wt%, sodium citrate 0.05wt%, Potassium sorbate 0.05wt%, L-calcium lactate 0.12wt%, DL-malic acid 0.1wt%, citric acid 0.1wt%, apple puree 10wt%, process water 70wt%.

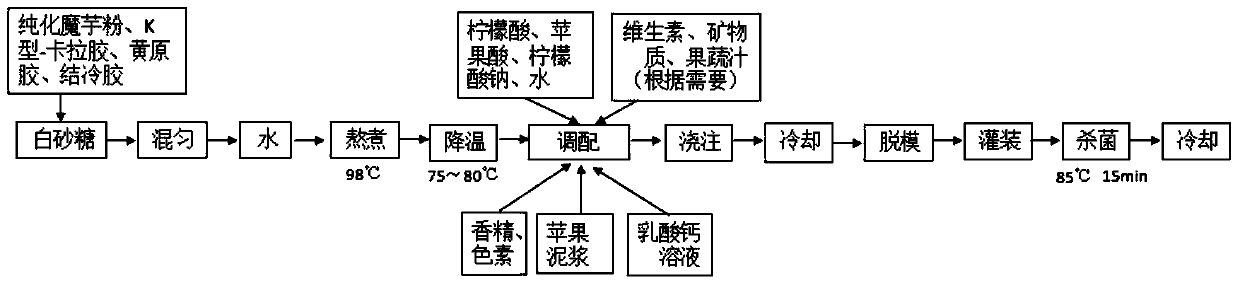

[0028] By the following methods, the gel food of the present embodiment has been manufactured:

[0029] (1) Preparation of calcium lactate solution: Weigh L-calcium lactate, dissolve it in 10 times the weight of hot water and set aside.

[0030] (2) Preparation of citric acid buffer: Weigh citric acid monohydrate, DL-malic acid, potassium citrate, sodium citrate, and potassium sorbate and dissolve them in 10 times the weight of hot water evenly for use.

[0031] (3) Preparation of apple puree: Weigh appl...

Embodiment 2

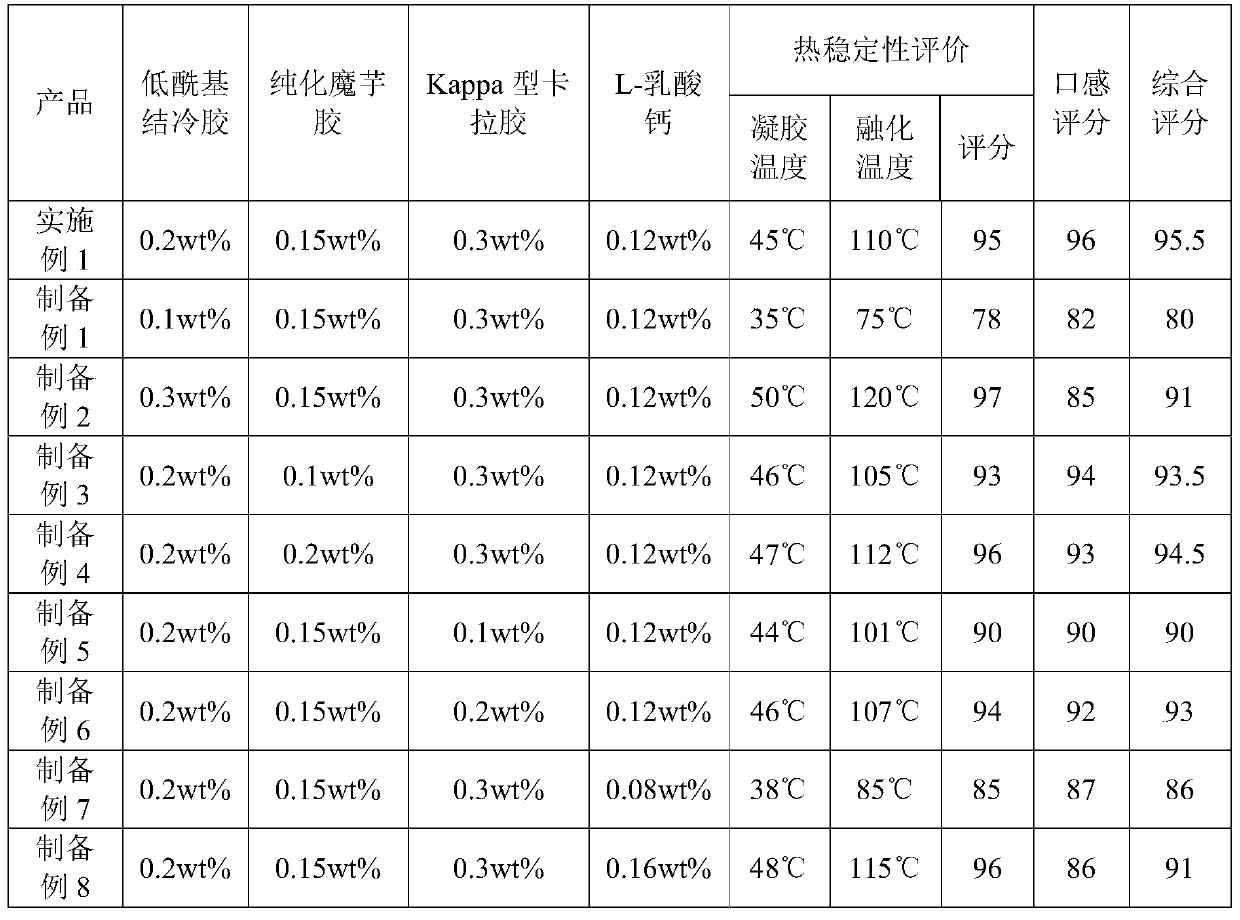

[0040] The selection of embodiment 2 gellan gum consumption

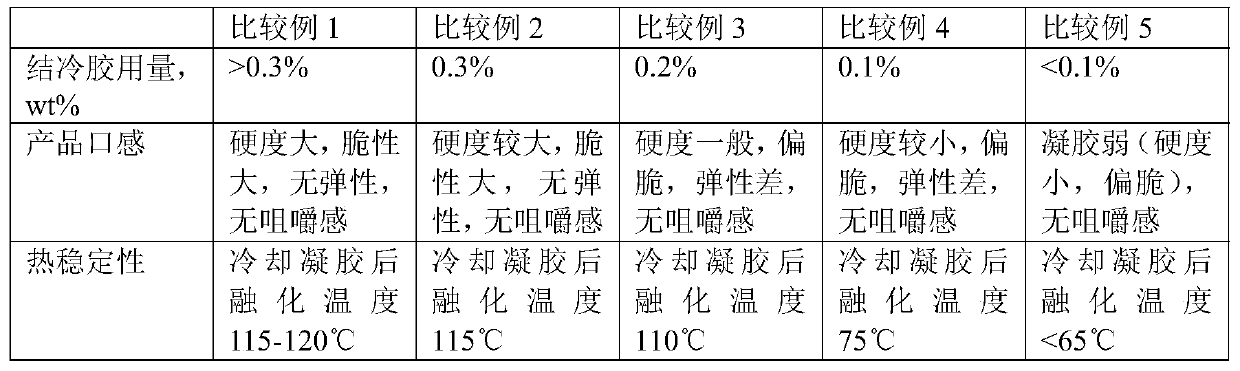

[0041] First, instead of using mixed gels to make gelatinized foods, gelled foodstuffs using only gellan gum as a gelling agent were tested. The following comparative examples 1-5 have used the same formula and method as Example 1, and the difference is that carrageenan, konjac gum and xanthan gum are not used, but only different amounts of gellan gum and 0.1wt% Calcium lactate, and study its impact on the mouthfeel of gel food, the results are shown in the following table 1:

[0042] Table 1 Effect of gellan gum dosage on the taste of gel food

[0043]

[0044] As can be seen from the above table, the gel food made of only gellan gum increases with the amount of use, and its hardness increases, but the mouthfeel is all brittle and has no sense of chewing. According to the above-mentioned test analysis, the present invention controls the amount of gellan gum at 0.1-0.3 wt%. And by adding thickeners such as pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com