Keratoprosthesis optical center area and preparation method thereof and keratoprosthesis

A technology of artificial cornea and center area, applied in medical science, prosthesis, eye implants, etc., can solve the problems of low success rate of corneal receptor treatment, lack of donor cornea sources, etc., achieve good hydrophilic performance, visible light The effect of high transmittance and excellent optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The embodiment of the present invention also provides a method for preparing the optical central zone of the artificial cornea, comprising the following steps:

[0032] Preparation of artificial cornea center material;

[0033] Soak the artificial cornea center material in a silane coupling agent solution, add a catalyst, and vibrate in an ultrasonic water bath in a closed environment for 1 to 2 hours to prepare an aminated artificial cornea center material;

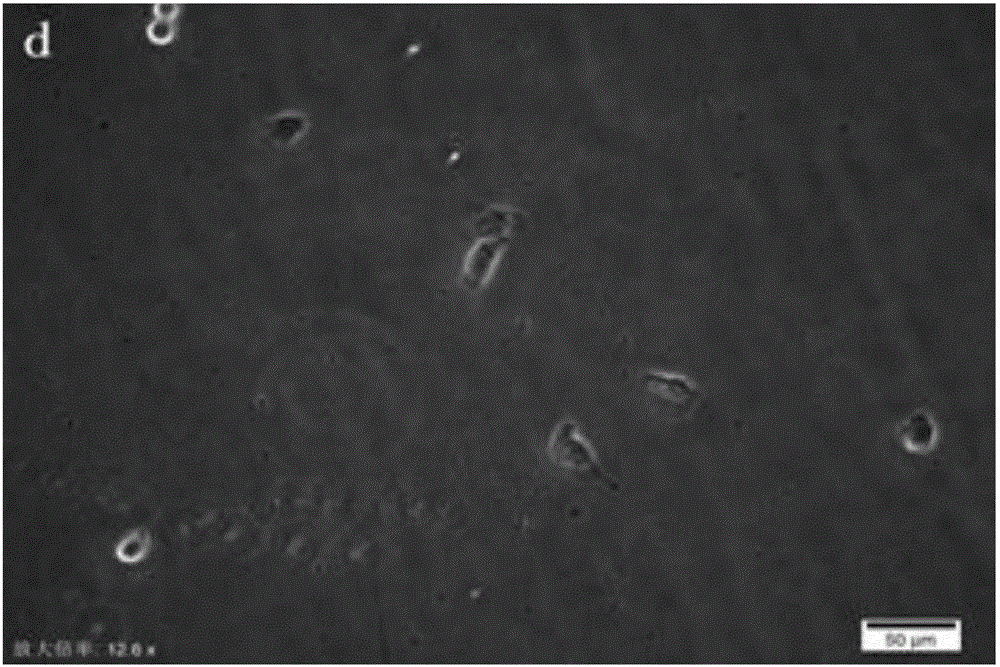

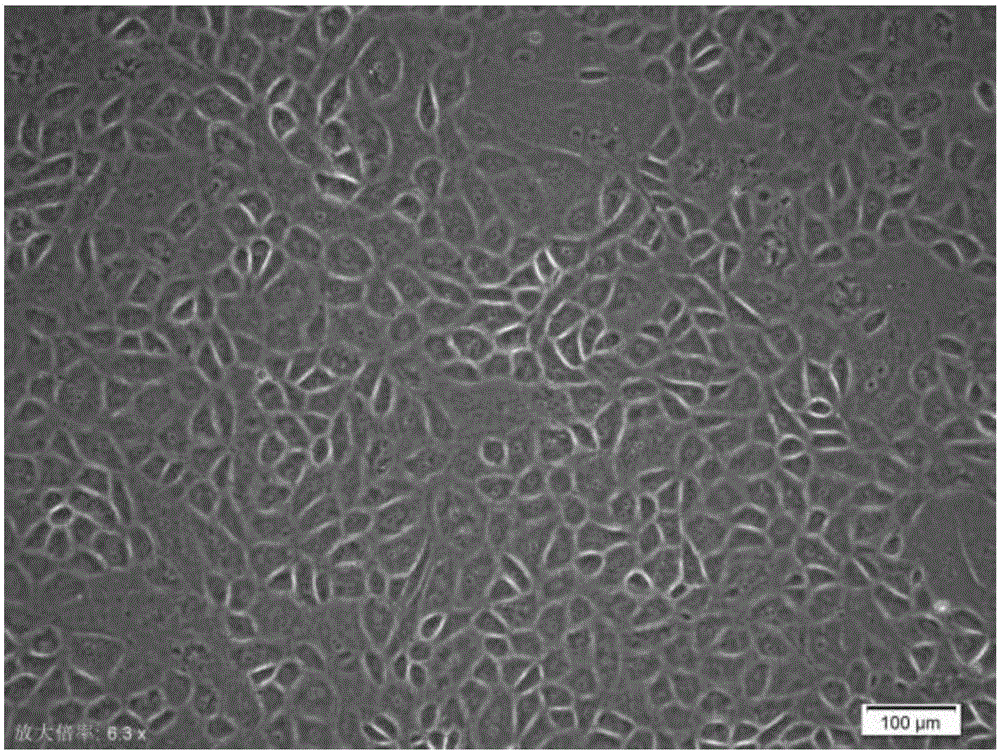

[0034] Wash the aminated artificial cornea center material with deionized water for 3 to 8 times, then place it in a solution of a heparin derivative or a heparin-like derivative, and react at room temperature for 10 to 20 hours to obtain the optical center of the artificial cornea; take out The optical central area of the artificial cornea is washed with phosphate buffer saline for 3 to 8 times.

[0035] In the method for preparing the optical central region of the artificial cornea provided by the embodiment ...

Embodiment 1

[0060] Preparation of the artificial corneal optical center zone:

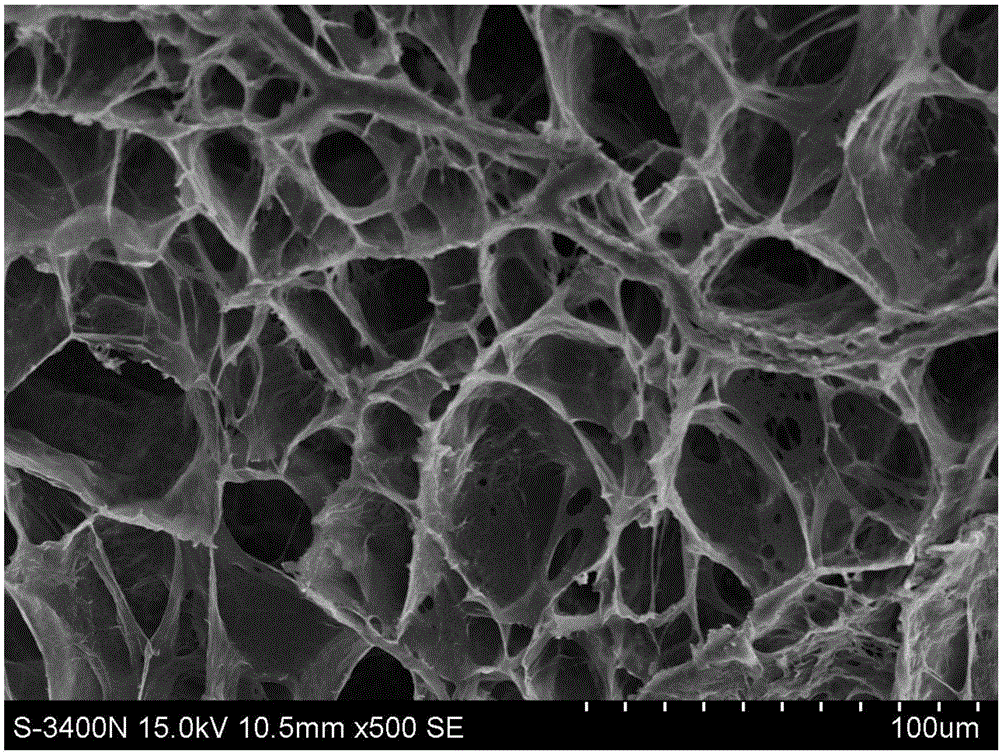

[0061] (1) Mix polyvinyl alcohol, water, and organic solvent evenly in a mass ratio of 1:1:10, inject into the hollow part of the mold and extend it into a film of a certain thickness; freeze at -50°C, and freeze for 5 to 20 Thaw at room temperature for 1 to 4 hours, repeat freezing and thawing for 6 to 10 times, and finally obtain an impermeable gel film. (2) Soak the non-water-permeable membrane in sterilized water for 5-10 days, and change the water once a day to obtain the artificial cornea central area material. (3) Cut out an appropriate amount of polyvinyl alcohol hydrogel film and soak it into the prepared silane coupling agent (APTS) solution, add an appropriate amount of catalyst, and vibrate in an ultrasonic water bath for 1 to 2 hours in a closed environment to obtain aminated polyvinyl alcohol hydrogel film. (4) Wash the aminated polyvinyl alcohol hydrogel film with deionized water for 3 to 8 ti...

Embodiment 2

[0068] Preparation of the artificial corneal optical center zone:

[0069] (1) Mix polyvinyl alcohol, water, and organic solvent evenly in a mass ratio of 1:2:10, inject into the hollow part of the mold and extend it into a film of a certain thickness; freeze at -50°C, and freeze for 5 to 20 Thaw at room temperature for 1 to 4 hours, repeat freezing and thawing for 6 to 10 times, and finally obtain an impermeable gel film. (2) Soak the non-water-permeable membrane in sterilized water for 5-10 days, and change the water once a day to obtain the artificial cornea central area material. (3) Cut out an appropriate amount of polyvinyl alcohol hydrogel film and soak it into the prepared silane coupling agent (APTS) solution, add an appropriate amount of catalyst, and vibrate in an ultrasonic water bath for 1 to 2 hours in a closed environment to obtain aminated polyvinyl alcohol hydrogel film. (4) Wash the aminated polyvinyl alcohol hydrogel film with deionized water for 3 to 8 ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com