A kind of method that improves lignin to butanol, acetone, ethanol adsorption performance in abe fermentation liquid

A technology of adsorption performance and lignin, applied in fermentation, chemical instruments and methods, separation/purification of hydroxyl compounds, etc., can solve the problems of high production cost, uneven lignin performance and unsatisfactory application performance of chemical methods, and achieve The preparation cost is low, the source is extensive and convenient, and the effect of solving the problem of product inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The method comprises the steps of:

[0031] (1) Classification of water-soluble lignin and water-insoluble lignin: fully mix 30g of corn alkali lignin with 500ml of distilled water for 20h, 40KHz ultrasonic assisted treatment for 2min, fully stir, settle and separate, filter with 0.45μm filter membrane, collect the sediment and filter the lower layer The solid was vacuum dried for 20 hours to obtain 17 g of water-insoluble lignin.

[0032] (2) Classification of ketone-soluble lignin and ketone-insoluble lignin: fully mix 17g of water-insoluble lignin and 500ml of acetone solvent for 18h, 40KHz ultrasonic assisted treatment for 3min, fully stir, settle and separate, filter with 0.45μm filter membrane, collect sediment and filter After the lower layer of solids, water-insoluble ketone-insoluble lignin is obtained.

[0033] (3) The product water-insoluble ketone-insoluble lignin was vacuum-dried at 50° C. for 15 hours to obtain 6 grams, which was bottled and sealed for st...

Embodiment 2

[0035] The method comprises the steps of:

[0036] (1) Classification of water-soluble lignin and water-insoluble lignin: Mix 50g of poplar lignin with 500ml of distilled water for 16h, ultrasonically assisted treatment for 3min, stir fully, settle and separate, filter with 0.45μm filter membrane, collect sediment and filter the lower solid Vacuum drying for 24 hours yielded 35 g of water-insoluble lignin.

[0037] (2) Classification of ketone-soluble lignin and ketone-insoluble lignin: fully mix 35g of water-insoluble lignin and 500ml of methyl ethyl ketone solvent for 20h, assisted by ultrasonic treatment for 2min, stir fully, settle and separate, filter with 0.45μm filter membrane, collect sediment and filter After the lower layer of solids, water-insoluble ketone-insoluble lignin is obtained.

[0038] (3) The product water-insoluble ketone-insoluble lignin was vacuum-dried at 45° C. for 18 hours to obtain 15 g, which was bottled and sealed for storage.

Embodiment 3

[0040] The method comprises the steps of:

[0041] (1) Classification of water-soluble lignin and water-insoluble lignin: fully mix 30g of wheatgrass lignin with 1000ml of distilled water for 18h, assisted by ultrasonic treatment for 3min, stir fully, settle and separate, filter with 0.45μm filter membrane, collect sediment and filter the lower solid Vacuum drying for 48 hours yielded 18 g of water-insoluble lignin.

[0042](2) Classification of ketone-soluble lignin and ketone-insoluble lignin: fully mix 18g of water-insoluble lignin and 1000ml of ketone solvent for 15h, assisted by ultrasonic treatment for 3min, stir fully, settle and separate, filter with 0.45μm filter membrane, collect sediment and filter After the lower layer of solids, water-insoluble ketone-insoluble lignin is obtained.

[0043] (3) The product water-insoluble ketone-insoluble lignin was vacuum-dried at 40° C. for 20 hours to obtain 7 g, which was bottled and sealed for storage.

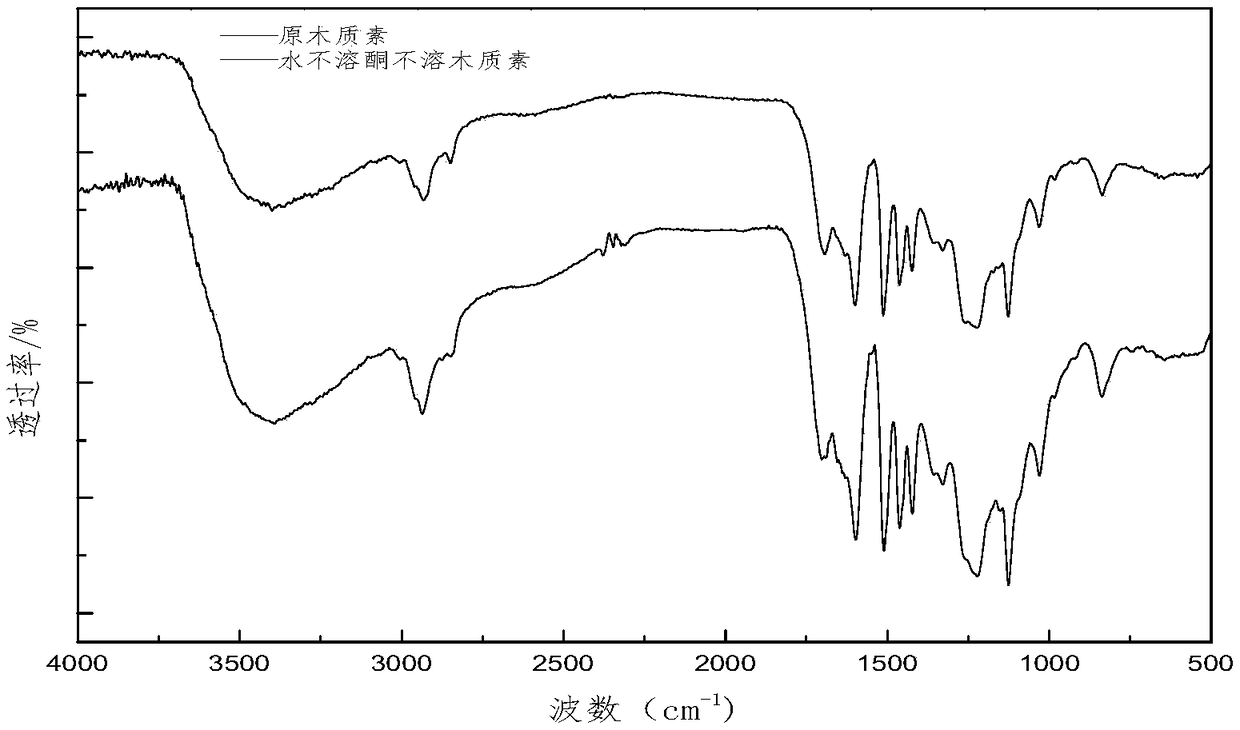

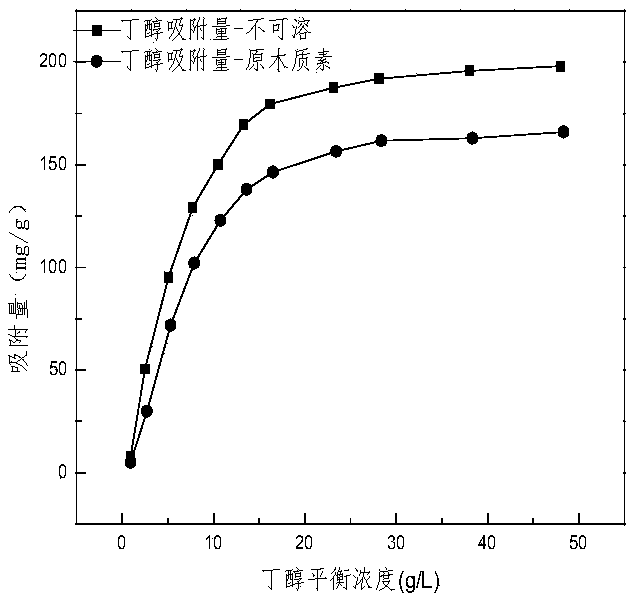

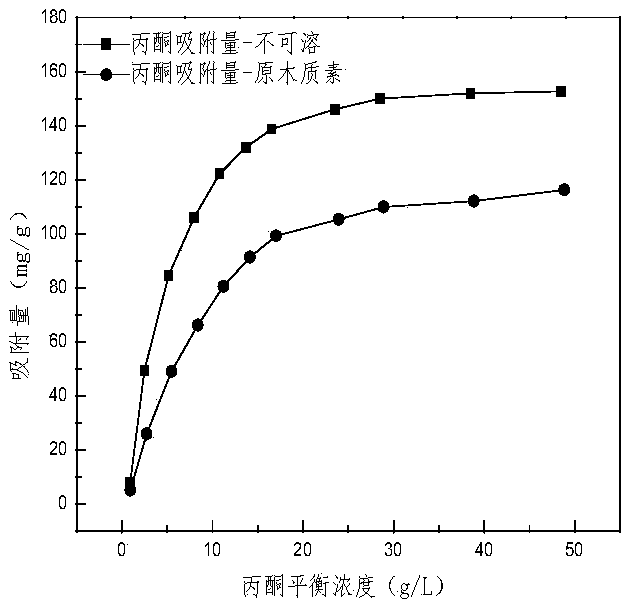

[0044] The Fourier t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com