Mechanical hand capable of working on any 3D curve and action process for mechanical hand

A manipulator and curve technology, applied in conveyors, manufacturing tools, destacking of objects, etc., can solve the problems of unstable running speed, inability to stop the manipulator, insufficient power, etc., to improve the degree of automation, flexible grasping mechanism, automation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

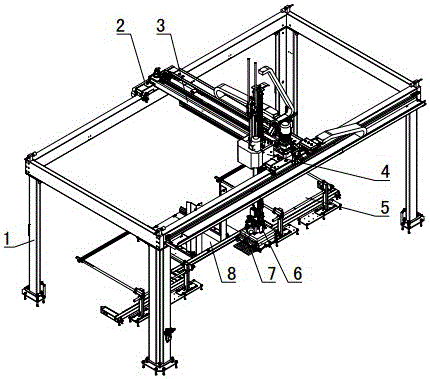

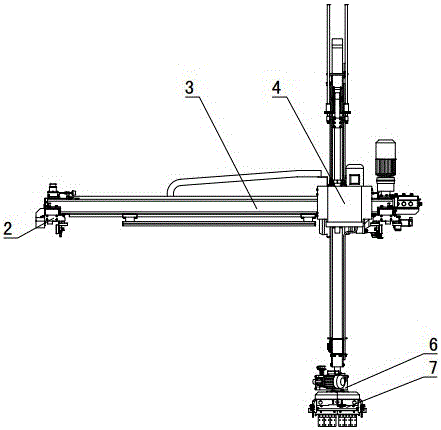

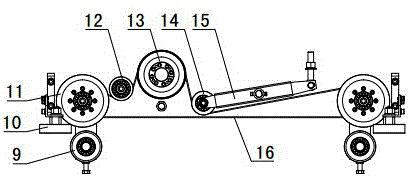

[0049] Figure 1~14 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~14 The present invention will be further described.

[0050] A manipulator that can work on any 3D curve, including a frame 1, a traveling mechanism, a w-axis rotating mechanism 6, and a grabbing mechanism 7. The traveling mechanism is installed on the frame 1 and can move along the x-axis, y-axis, and z-axis respectively. Move, the w-axis rotation mechanism 6 is installed on the walking mechanism, and the grasping mechanism 7 is installed on the w-axis rotation mechanism 6; Mechanism and Tile Grabbing Mechanism. The grasping mechanism 7 of the manipulator is installed on the w-axis rotation mechanism 6, which increases the degree of freedom of the grasping mechanism 7 and makes the grasping mechanism 7 more flexible, so that the manipulator can also control the posture of the tiles while moving the tiles. It can be transformed so that the tiles can be stacke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com