Industrial preparation method of O-carboxymethyl chitosan

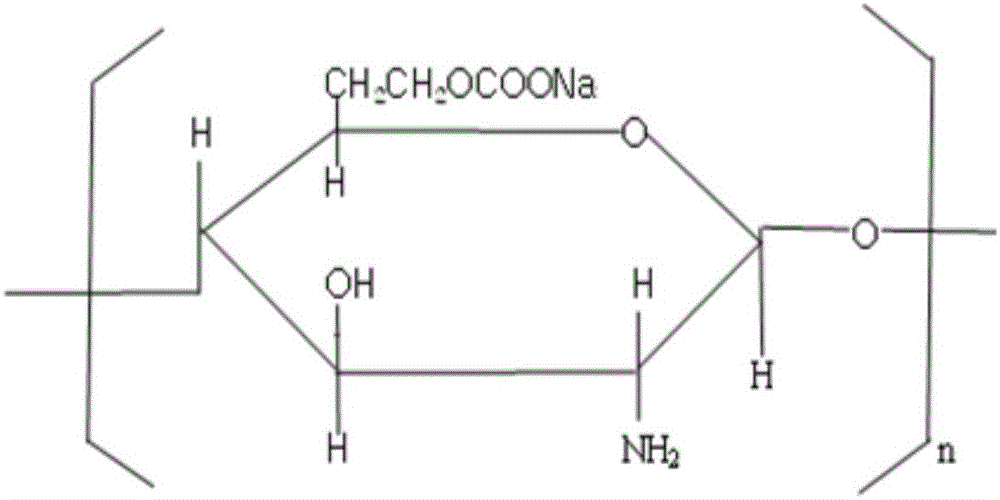

A technology of carboxymethyl chitosan and chitosan, which is applied in the field of industrialized preparation of O-carboxymethyl chitosan, can solve problems such as toxic organic compounds, and achieve the effects of preventing oxidation, ensuring quality and ensuring yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

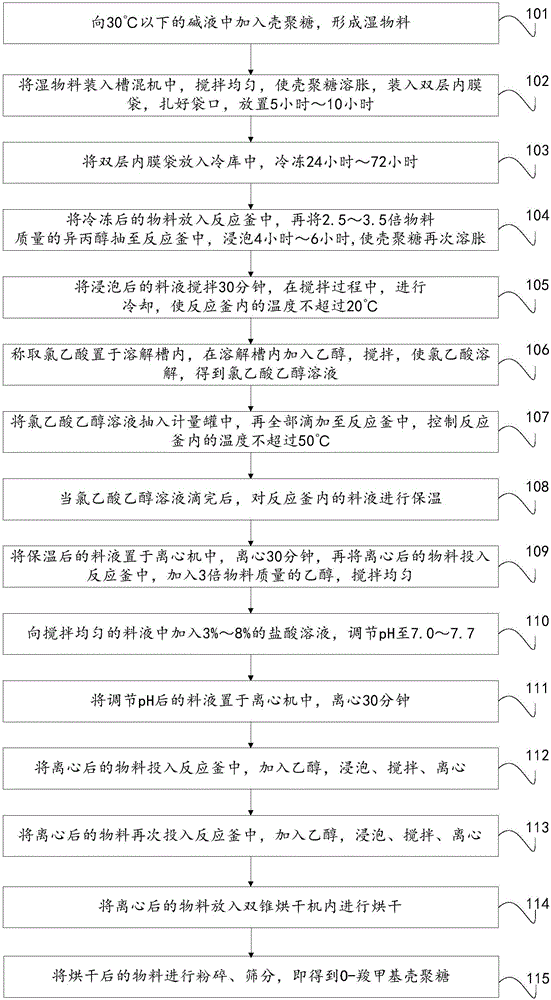

[0038] The preparation method that the embodiment of the present invention provides comprises the following steps:

[0039] S101, adding chitosan to the alkaline solution below 30°C to form a wet material.

[0040] Wherein, the added chitosan is preferably chitosan made from crab shells with a fineness exceeding 40 mesh after crushing.

[0041] The proportion of chitosan in the wet material is 25% to 35%.

[0042] Of course, before adding chitosan, the configuration of lye should be carried out first. In this example, water and caustic soda are mixed according to the mass ratio of 1:0.7 to 1:2, and stirred to dissolve the alkali to obtain lye, and cool the lye to below 30°C.

[0043] S102, put the wet material into the tank mixer, stir evenly to make the chitosan swell, put it into a double-layer inner membrane bag, tie the mouth of the bag, and let it stand for 5 to 10 hours.

[0044] S103, put the double-layer inner film bag into the cold storage, and freeze for 24 hours ...

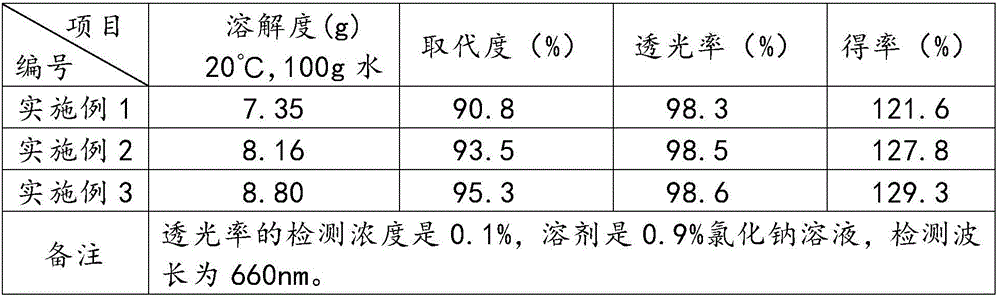

Embodiment 1

[0073] 1) Mix 100kg of caustic soda and 100kg of purified water into a 1:1 lye, and when the temperature of the lye drops to 30°C, add 100kg of chitosan into the lye, and mix it fully with a tank mixer. Then pass through a 40-mesh sieve, put it into a double-layer inner film bag, tie the mouth of the bag, leave it for 6 hours, and then put it into a freezer at -18°C for 48 hours.

[0074] 2) Put the frozen material into the reactor, add 800kg of isopropanol and vacuum pump it into the reactor, soak for 4 hours.

[0075] 3) Stir the soaked feed liquid for 30 minutes. During the stirring process, start the cooling system at the same time to ensure that the temperature in the kettle does not exceed 20°C.

[0076] 4) 120kg of chloroacetic acid and 40kg of ethanol above 95% are formulated into a chloroacetic acid ethanol solution, which is pumped into a metering tank.

[0077] 5) Slowly add the ethanol solution of chloroacetic acid in the metering tank dropwise to the reaction ket...

Embodiment 2

[0085] 1) Prepare 100kg of caustic soda and 110kg of purified water to make a 1:1.1 lye, when the temperature of the lye drops to 30°C, add 100kg of chitosan into the lye, fully stir and mix with the tank mixer, Then pass through a 40-mesh sieve, put it into a double-layer inner film bag, and tie the mouth of the bag; after standing for 7 hours, put it into a freezer at -18°C for 60 hours.

[0086] 2) Put the frozen material into the reactor, add 800kg of isopropanol and vacuum pump it into the reactor, soak for 5 hours.

[0087] 3) Stir the soaked feed liquid for 30 minutes, and start the cooling system at the same time to ensure that the temperature in the kettle does not exceed 20°C.

[0088] 4) 120kg of chloroacetic acid and 40kg of ethanol above 95% are formulated into a chloroacetic acid ethanol solution, which is pumped into a metering tank.

[0089] 5) Slowly add the ethanol solution of chloroacetic acid in the metering tank dropwise to the reaction kettle, control th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com