Preparation method for elastic fluorocarbon paint

A fluorocarbon coating and elastic technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of building landscape impact and inability to cover up, achieve excellent thermal insulation performance, excellent ultra-long anti-corrosion performance, and improve aesthetics Effect

Inactive Publication Date: 2017-02-01

TIANJIN MEISHIBANG PAINT CHEM IND

View PDF2 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

These cracks cannot be concealed if ordinary paint is applied, leaving the view of the building unaffected

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

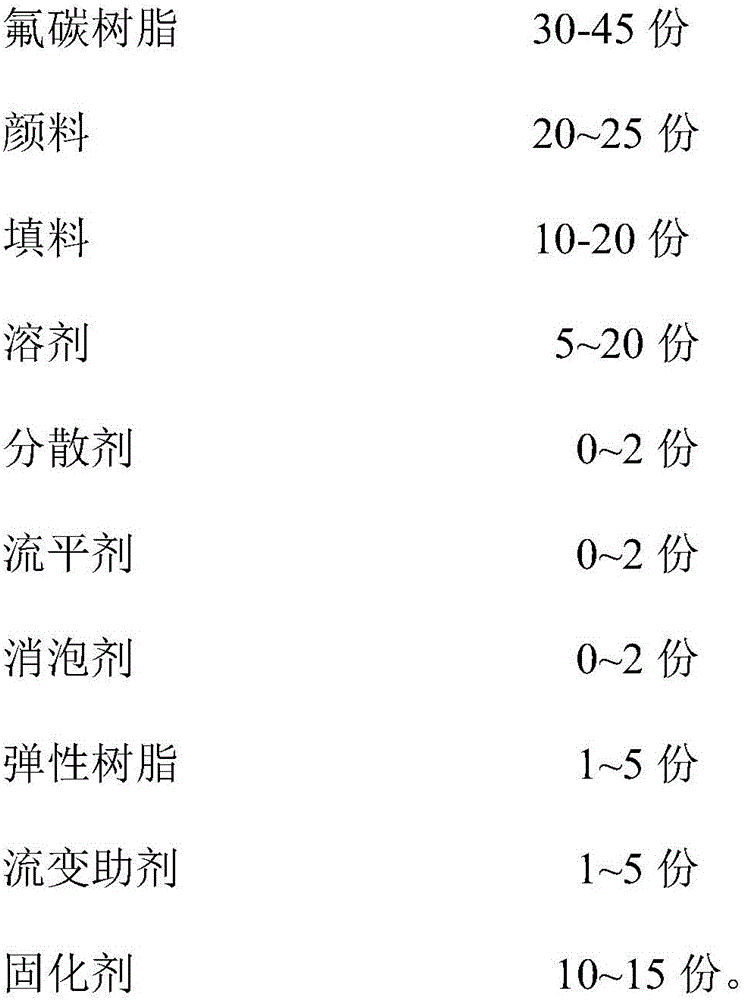

[0029] An elastic fluorocarbon coating which is prepared by including the following parts by weight of raw materials:

[0030]

Embodiment 2

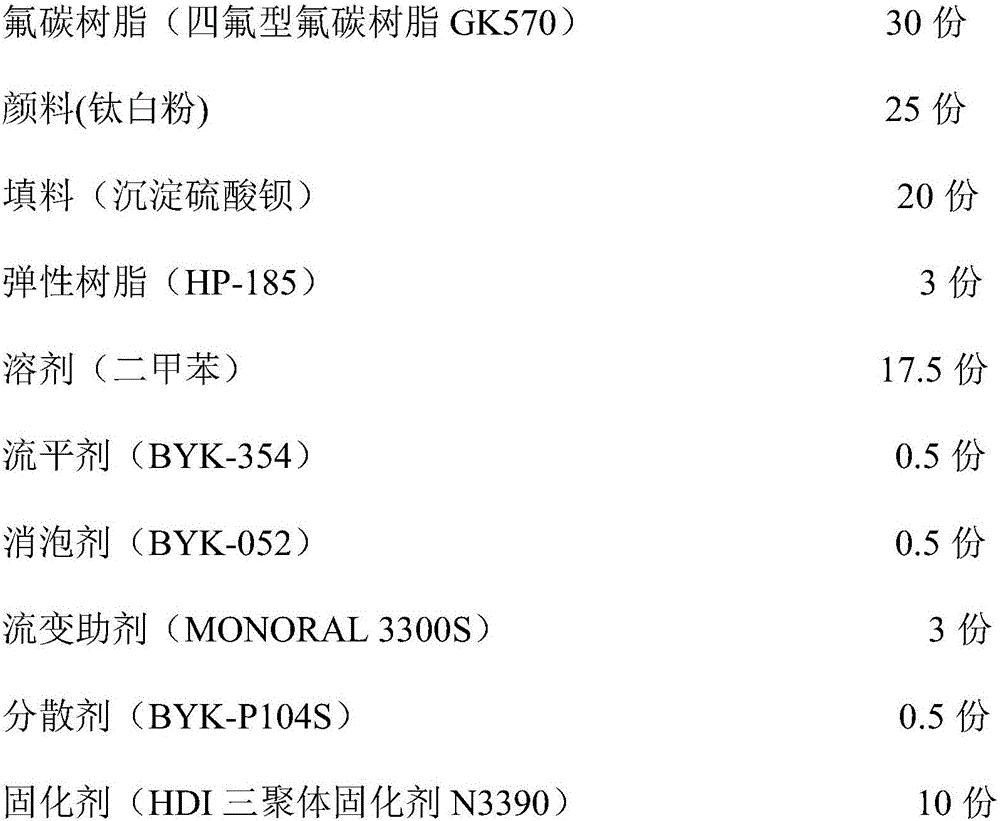

[0032] An elastic fluorocarbon coating which is prepared by including the following parts by weight of raw materials:

[0033]

[0034]

Embodiment 3

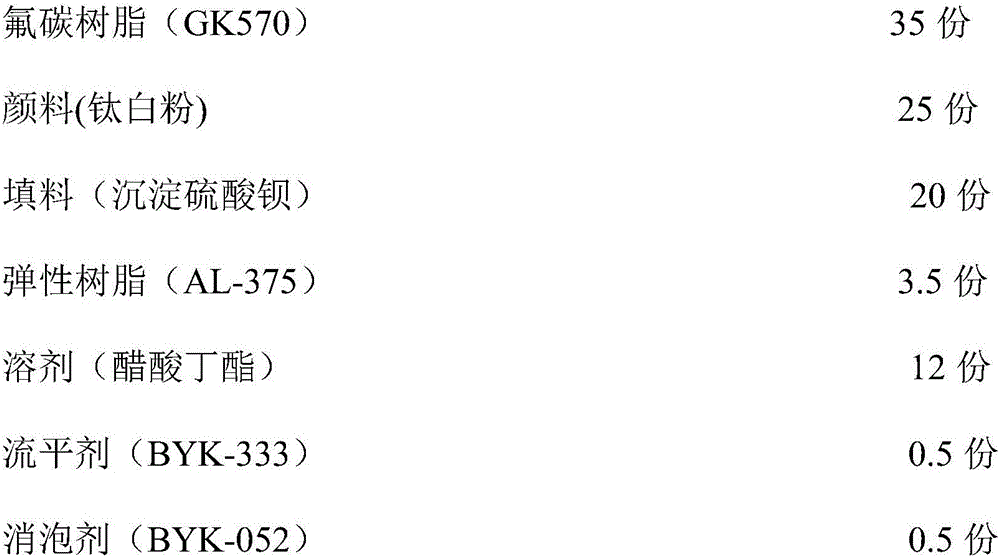

[0036] An elastic fluorocarbon coating which is prepared by including the following parts by weight of raw materials:

[0037]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a preparation method for elastic fluorocarbon paint. The preparation method for the elastic fluorocarbon paint includes the steps: (1) uniformly stirring fluorocarbon resin, partial solvents and dispersing agents in a stirrer; (2) adding the dispersing agents, pigments and fillers, and grinding to obtain grinding thick liquid; (3) placing the grinding thick liquid in the stirrer, sequentially adding elastic resin, defoaming agents and flatting agents, and uniformly stirring; (4) sequentially adding theological additives and residual solvents after the thick liquid is dispersed, and uniformly stirring to obtain main agents; (5) individually packaging curing agents to obtain packaged curing agents. According to the paint, anti-aging protection life of a coated substance can reach 25 years or more, and the paint has low VOCs (volatile organic compounds) and is better in toughness and elasticity and applicable to bridge concrete base surfaces, positions with easily cracked surfaces such as tunnels and piers and surfaces of other buildings with a certain water-proof and anticorrosion requirement.

Description

Technical field [0001] The present invention relates to an elastic fluorocarbon coating, in particular to a coating that has weather resistance for more than 25 years, excellent toughness and elasticity, and good protection for cracking concrete surfaces. Background technique [0002] Due to the internal stress of the concrete, small cracks usually appear on the surface of the concrete substrate of some bridge culverts and piers. If ordinary paint is applied, these cracks cannot be concealed and the building landscape is affected. [0003] The invention adopts the elastic fluorocarbon coating, so that the coating film has good stretchability, can maintain the integrity of the coating film when the substrate is cracked, and effectively saves the cost of surface treatment. Summary of the invention [0004] In view of this, the purpose of the present invention is to provide an elastic fluorocarbon coating with low VOC content, meeting the requirements for exemption of solvent-based co...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D127/12C09D201/00C09D5/08C09D7/12

CPCC09D127/12C08L2205/03C09D5/08C08L101/00C08K13/02C08K5/34924C08K13/06C08K9/04C08K3/346C08K2003/3045C08K2003/2241

Inventor 马翔宇于涛

Owner TIANJIN MEISHIBANG PAINT CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com