Mechanism capable of improving parallel light ejection of LED exposure machine

A technology of parallel light and exposure machine, which is applied in the field of etching, circuit board exposure, and development, and can solve the problems that affect the processing accuracy of PCB board 5 and cannot reach the processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

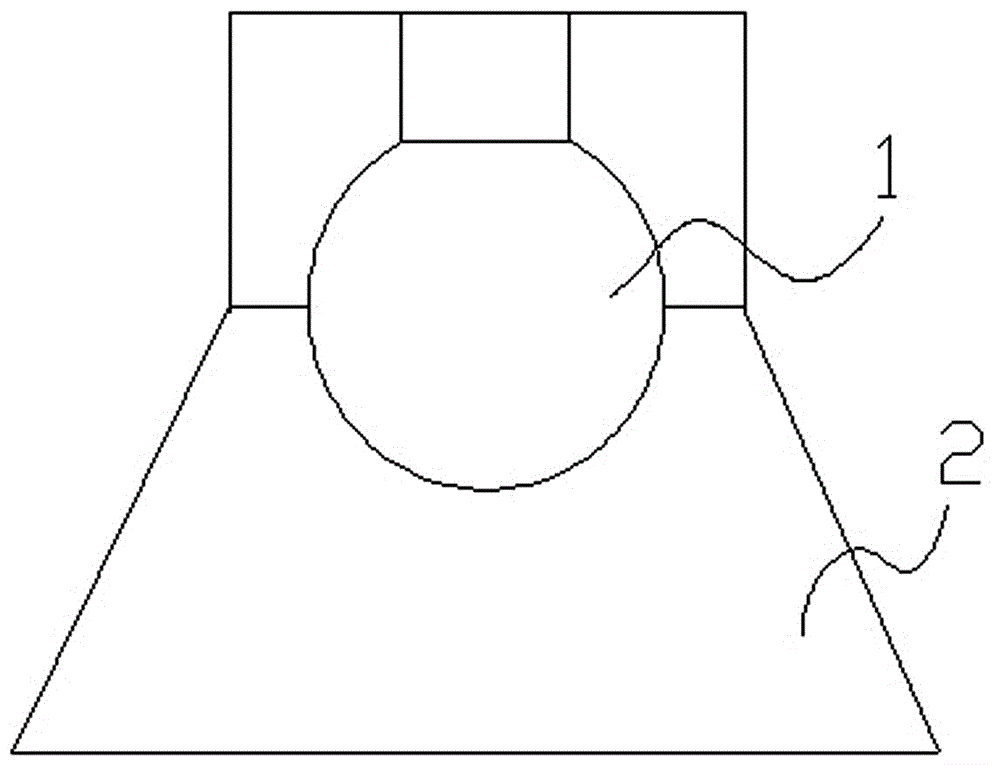

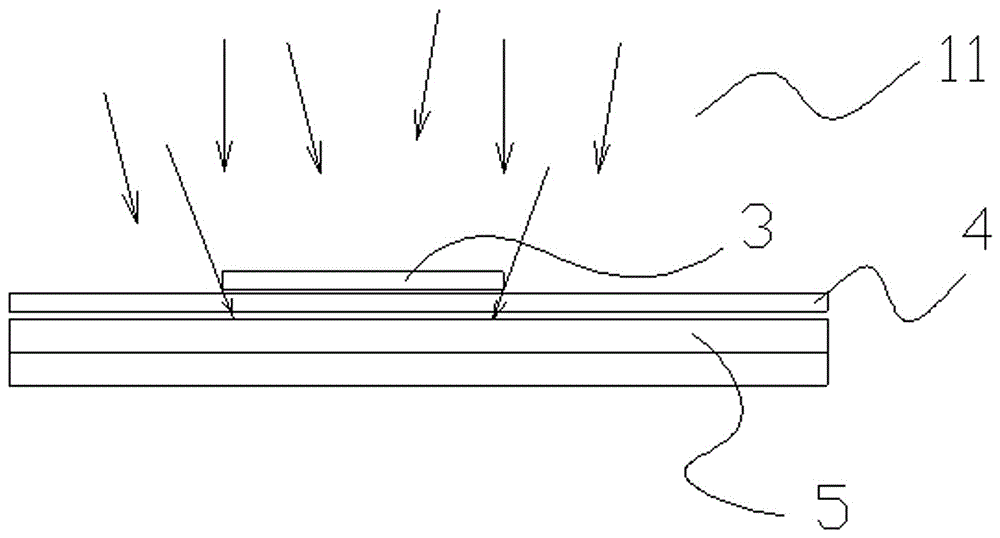

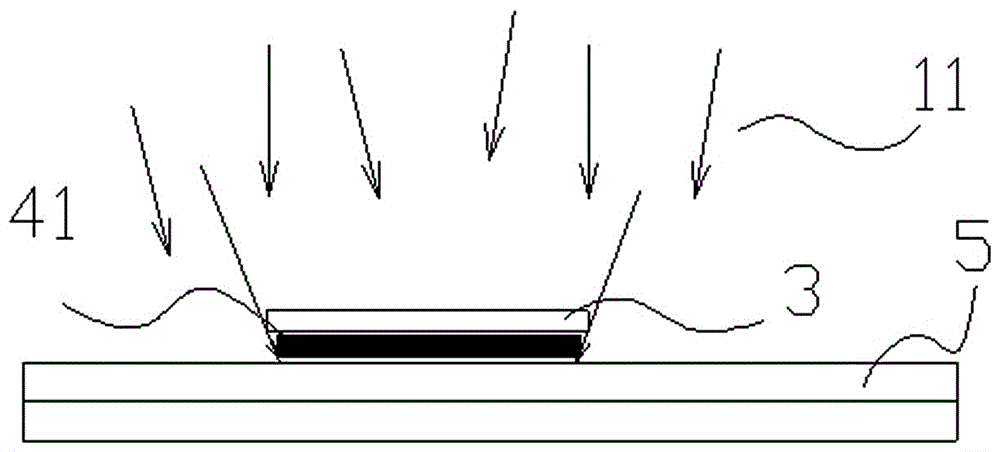

[0020] See attached Figure 4~7 , an improved parallel light emission mechanism of an LED exposure machine, comprising a PCB board 5, a light source 1 and a reflective cup 2, the reflective cup 2 is fixed on the PCB board 5, and the light source 1 is fixed on the PCB board 5 at the inner focus position of the reflective cup 2, A light guide cover 7 is also included, and the light guide cover 7 is fixed on the open end of the reflective cup 2 and coaxial with the reflective cup 2 .

[0021] The light guide cover 7 is coated with a light-absorbing material.

[0022] The light guide cover 7 is preferably made of aluminum.

[0023] The light guide cover 7 is made of high temperature resistant plastic material.

[0024] The light guide cover 7 is made of glass material.

[0025] When the present invention is used, the light source 1 generates light after it is energized. Due to the objective problems of the processing accuracy of the reflective cup 2 and the assembly accuracy of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com