Temperature control system and temperature control method for microbial decomposition process of organic matters

A temperature control system and microbial decomposition technology, applied in the preparation of organic fertilizers, the treatment of biological organic parts, organic fertilizers, etc., can solve the problems of reducing the amount of decomposition, prone to odor, odor, etc. fast growing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

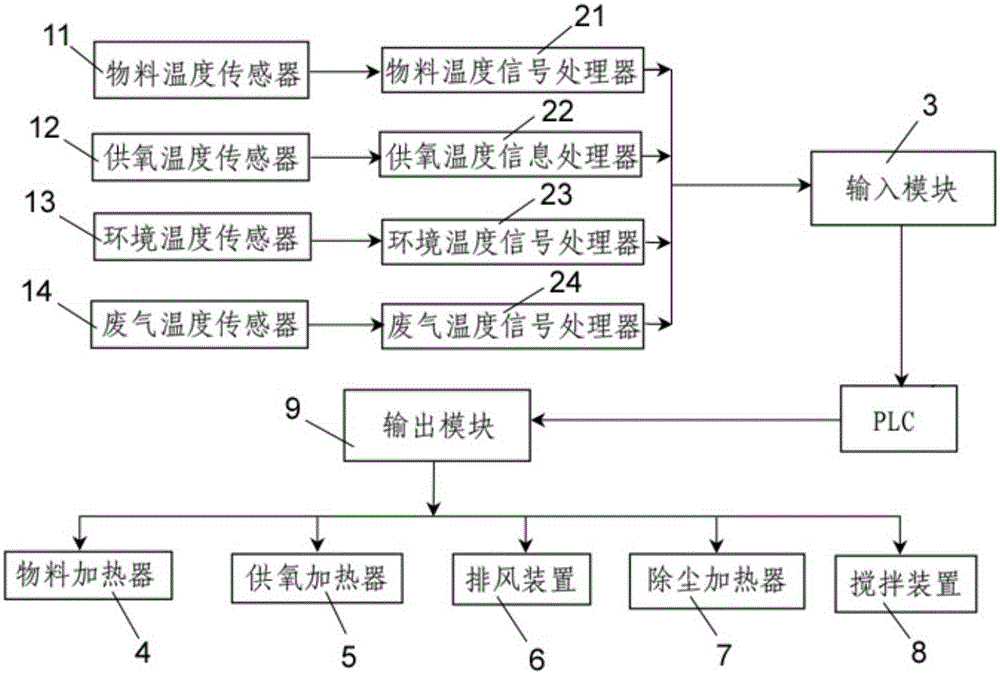

[0030] A temperature control system for the microbial decomposition process of organic matter, such as figure 1 As shown, it includes: material temperature sensor 11, oxygen supply temperature sensor 12, ambient temperature sensor 13, exhaust gas temperature sensor 14, material temperature signal processor 21 corresponding to each temperature sensor, oxygen supply temperature signal processor 22, and ambient temperature signal Processor 23, waste gas temperature signal processor 24, material heater 4, oxygen supply heater 5, exhaust device 6, dust removal heater 7 and stirring device 8. The signal wires of each temperature signal processor are connected to the input module 3 respectively.

[0031] Among them, the material temperature sensor 11 is arranged on the inner wall of the discharging door of the decomposition chamber to contact the material, the oxygen supply temperature sensor 12 is arranged in the oxygen supply duct, the ambient temperature sensor 13 is arranged at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com