Range hood provided with position-sensorless brushless direct-current motor and control method thereof

A DC brushless, range hood technology, applied in the direction of electronic commutation motor control, single motor speed/torque control, control system, etc., can solve the problems that cannot meet the user's operation requirements, and have not proposed the implementation plan of the speed control module. , to achieve the effect of simple and reasonable structure, low power consumption and large torque range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the present invention is described in further detail:

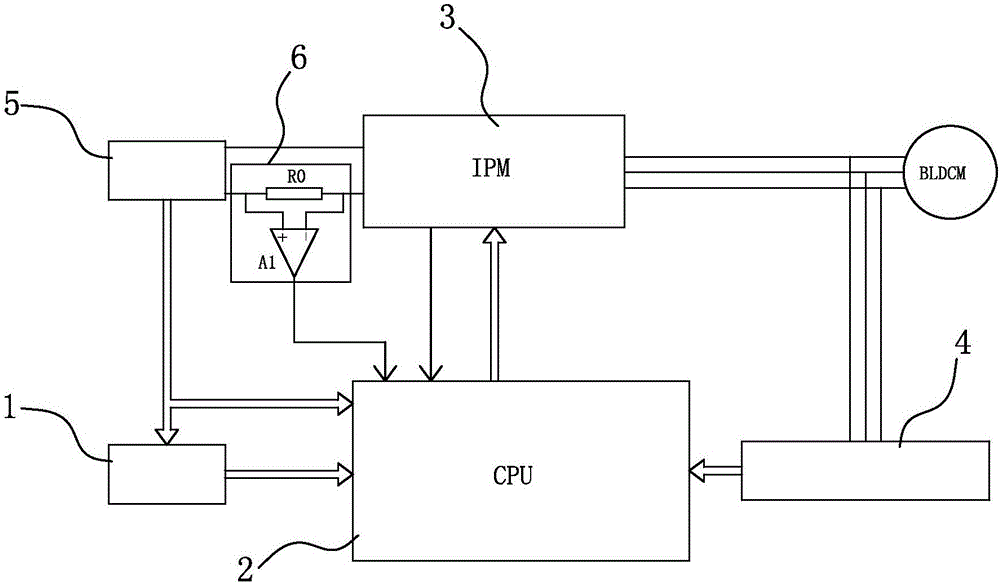

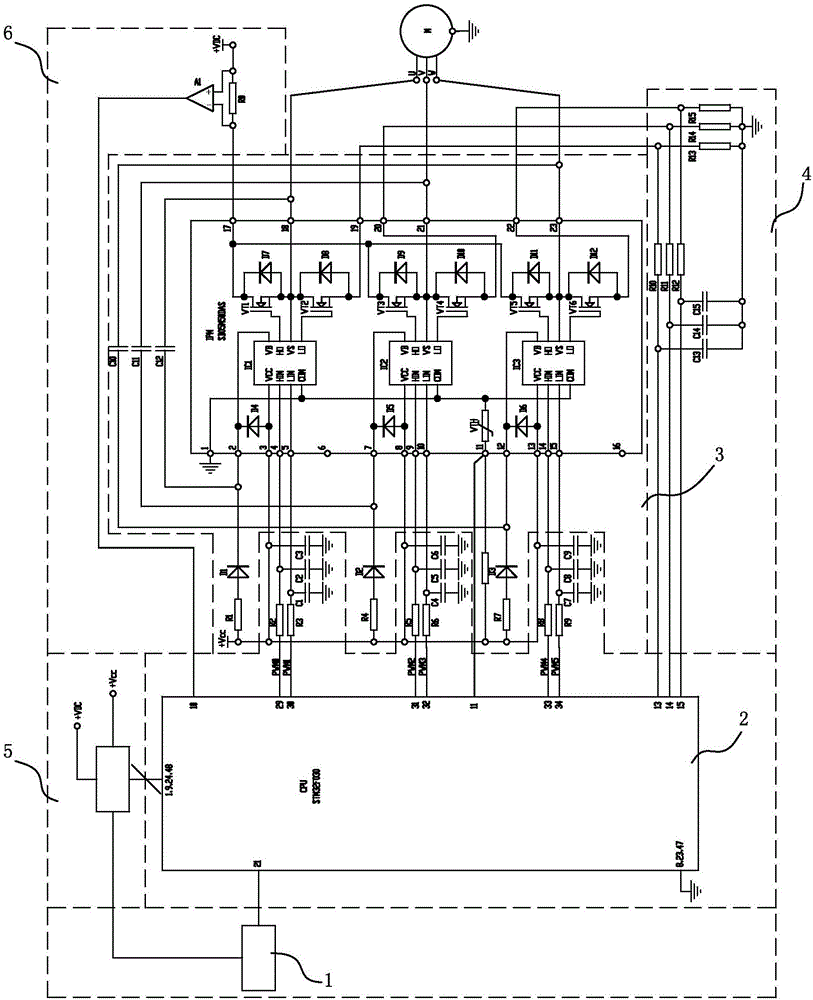

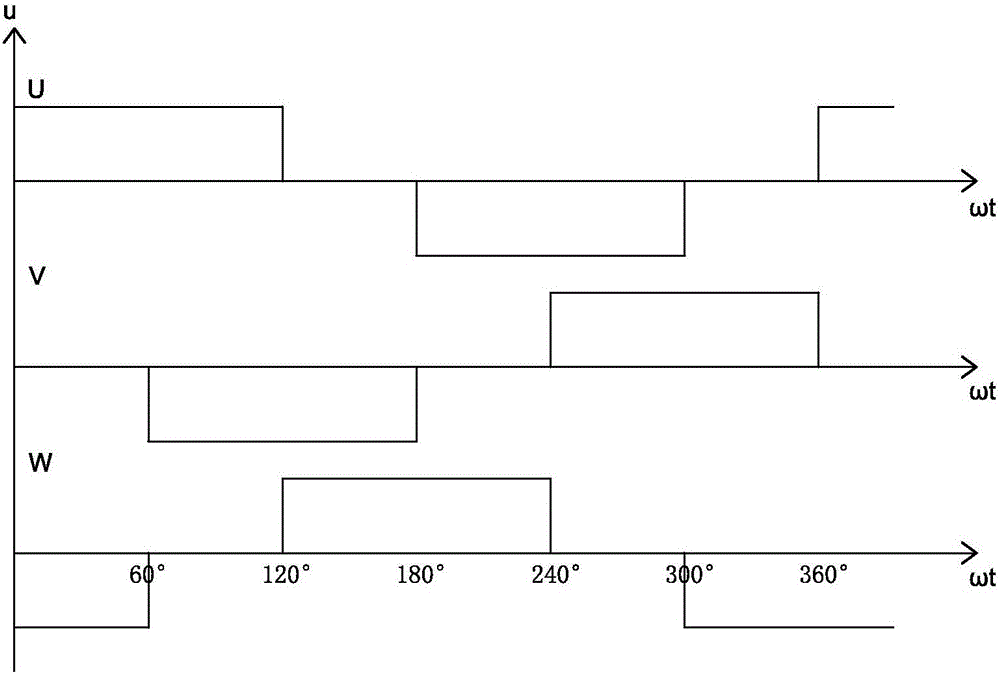

[0031] Such as Figure 1 to Figure 3 As shown, according to an embodiment of a range hood with a DC brushless position sensorless motor provided by the present invention, it includes a connected speed setting unit 1, a CPU microprocessor 2, a current sampling unit 6, and a counter electromotive force Zero detection unit 4 and the power supply 5 that provides power to the speed given unit 1 and the CPU microprocessor 2, the speed given unit 1 is a man-machine control panel, and also includes an IPM three-phase full-bridge intelligent power amplification unit 3 , the IPM three-phase full-bridge intelligent power amplification unit 3 includes a core unit, a temperature overrun monitoring unit and a three-phase inverter unit, and the CPU microprocessor 2 performs A / D conversion on the speed regulation signal input by the speed given unit 1 And after calculation, output t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com