Magnet molding magnetic field monitoring magnetizing device

A technology for magnetizing devices and magnetizing magnetic fields, which is applied to measuring devices, magnetic objects, and measuring magnetic variables. It can solve the problems of affecting the efficiency of magnetization and the inability to monitor the magnetizing magnetic field, so as to reduce costs, improve monitoring capabilities, and improve usage. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

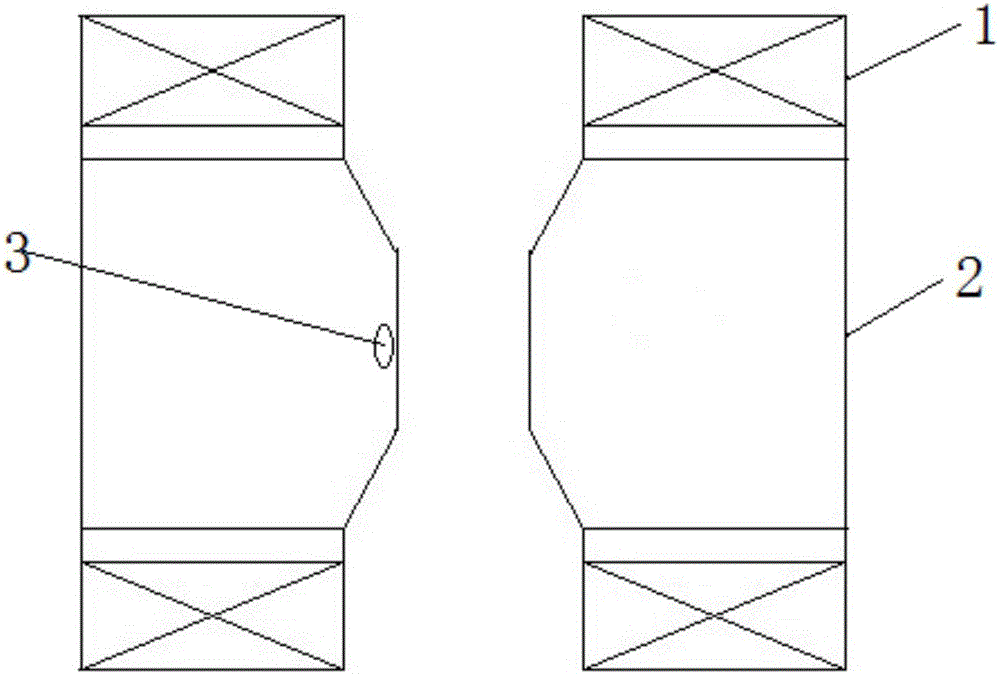

[0029] In this embodiment, the magnet forming magnetic field monitoring and magnetizing device includes a magnetizing magnetic head, which provides a magnetizing magnetic field for magnetizing the magnet, and the magnet forming magnetic field monitoring and magnetizing device also includes a Hall element and a display controller. The element detects the magnetized magnetic field and outputs a measurement signal to the display controller, and the display controller receives the measurement signal and displays it; the Hall element has one, and is arranged on the magnetized magnetic head.

Embodiment 2

[0031] In this embodiment, the magnet forming magnetic field monitoring and magnetizing device includes a magnetizing magnetic head, which provides a magnetizing magnetic field for magnetizing the magnet, and the magnet forming magnetic field monitoring and magnetizing device also includes a Hall element and a display controller. The element detects the magnetizing magnetic field and outputs a measurement signal to the display controller, and the display controller receives the measurement signal and displays it; there are two Hall elements, and they are arranged on the magnetization head.

Embodiment 3

[0033] In this embodiment, the magnet forming magnetic field monitoring and magnetizing device includes a magnetizing magnetic head, which provides a magnetizing magnetic field for magnetizing the magnet, and the magnet forming magnetic field monitoring and magnetizing device also includes a Hall element and a display controller. The element detects the magnetizing magnetic field and outputs a measurement signal to the display controller, and the display controller receives the measurement signal and displays it; there are three Hall elements, and they are arranged on the magnetization head.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture toughness | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com