Rotary cutting operation assembly

A technology of components and moving parts, which is applied in the field of living body detection and sampling devices for medical operations, can solve the problems of unstable operation of rotary cutting operation components, complex structure of rotary cutting operation components, cumbersome manual operation, etc., and achieve high efficiency of surgical rotary cutting, It is difficult to interfere and ensures the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

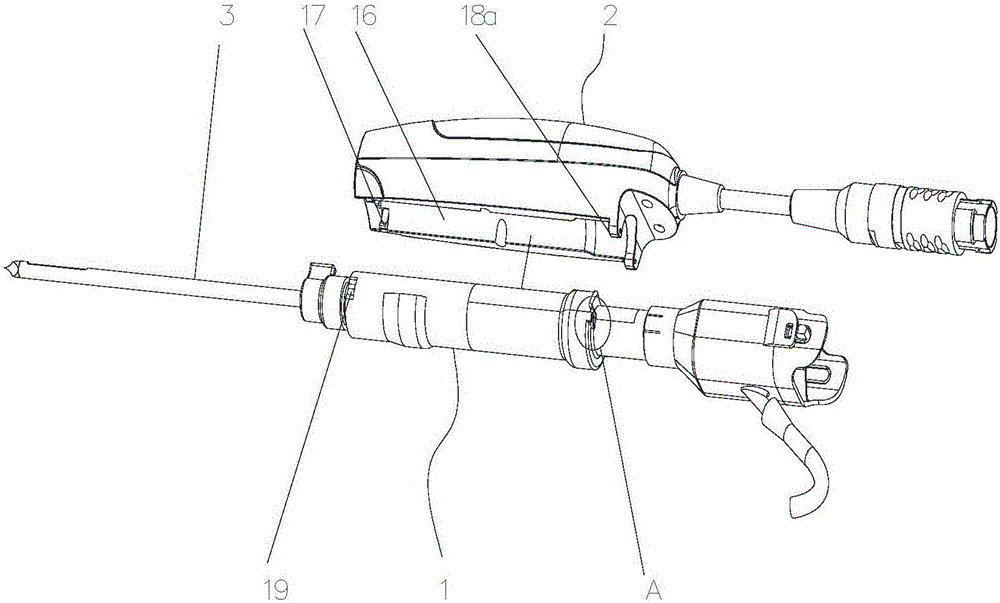

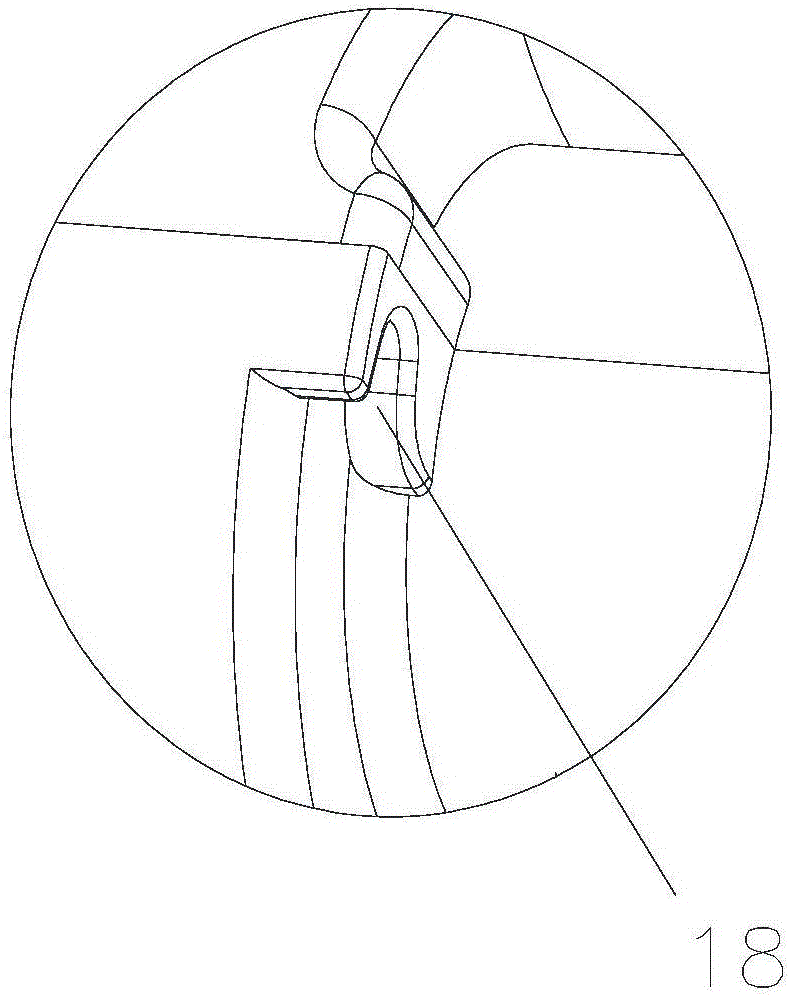

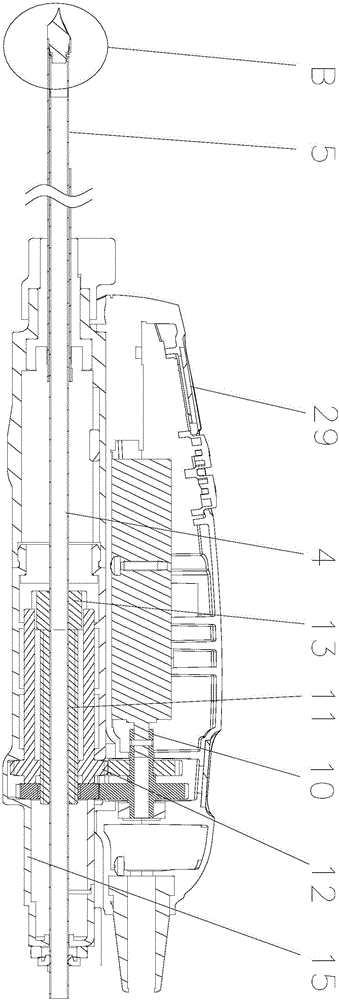

[0024] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 Enlarged view of A in the middle, image 3 It is another structural schematic diagram of the present invention, Figure 4 for image 3 Enlarged view of middle B, Figure 5 for Figure 4 Enlarged image at middle C; Figure 6 It is a structural schematic diagram of the driving mechanism in the present invention, Figure 7 for Figure 6 The left view, as shown in the figure, includes a knife 1 and a handle 2 fixedly installed on the knife 1, the knife at least includes an outer knife 3 with a sampling groove 5 at the front end and an inner knife 4 sleeved on the outer knife 3;

[0025] The tool 1 also includes a rotational follower 6 that is axially slidably engaged with the inner knife 4 in the circumferential direction and a translational follower 7 that cooperates with the inner knife 4 through a screw structure; the handle 2 includes a handle body and a mounting The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com