System and method for disposing house refuse

A technology for domestic garbage and garbage charcoal, which is applied in chemical instruments and methods, transportation and packaging, and solid waste removal, etc., can solve the problems of complex water quality of landfill leachate, high cost, and difficulty in leachate treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

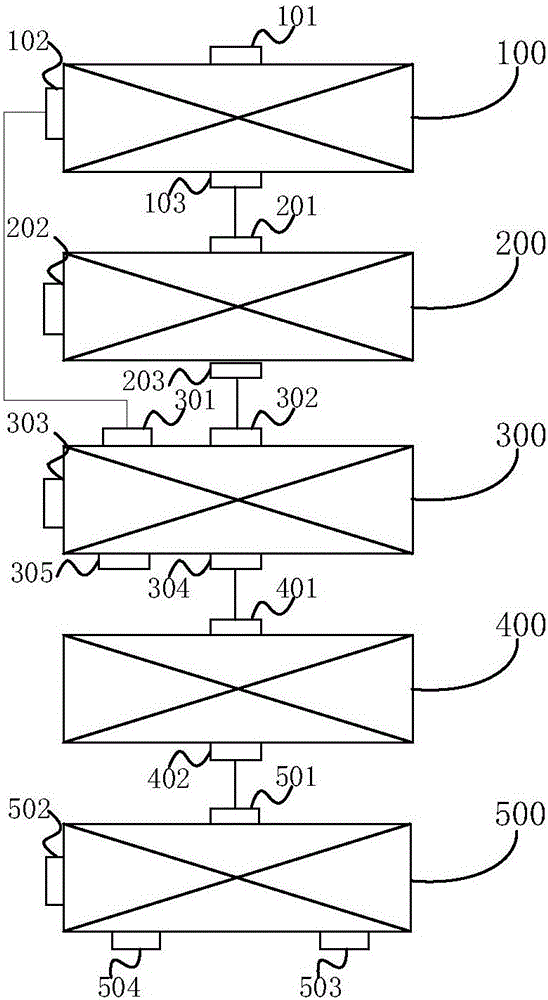

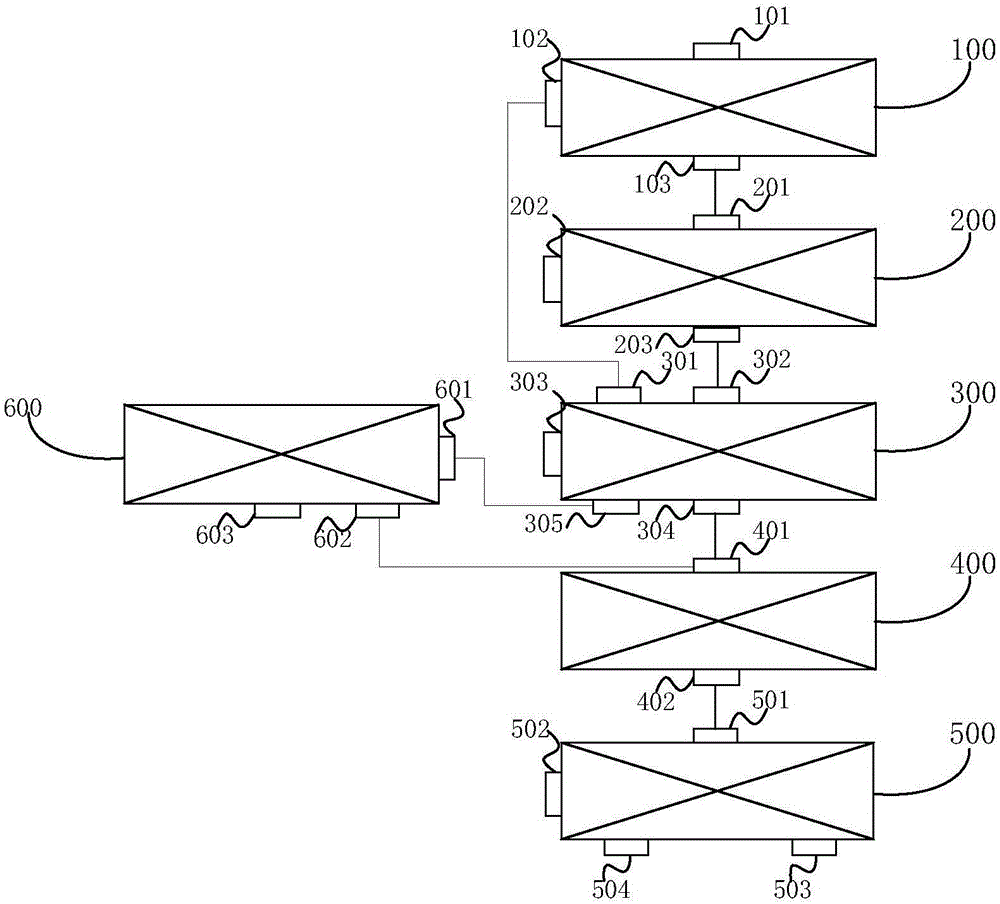

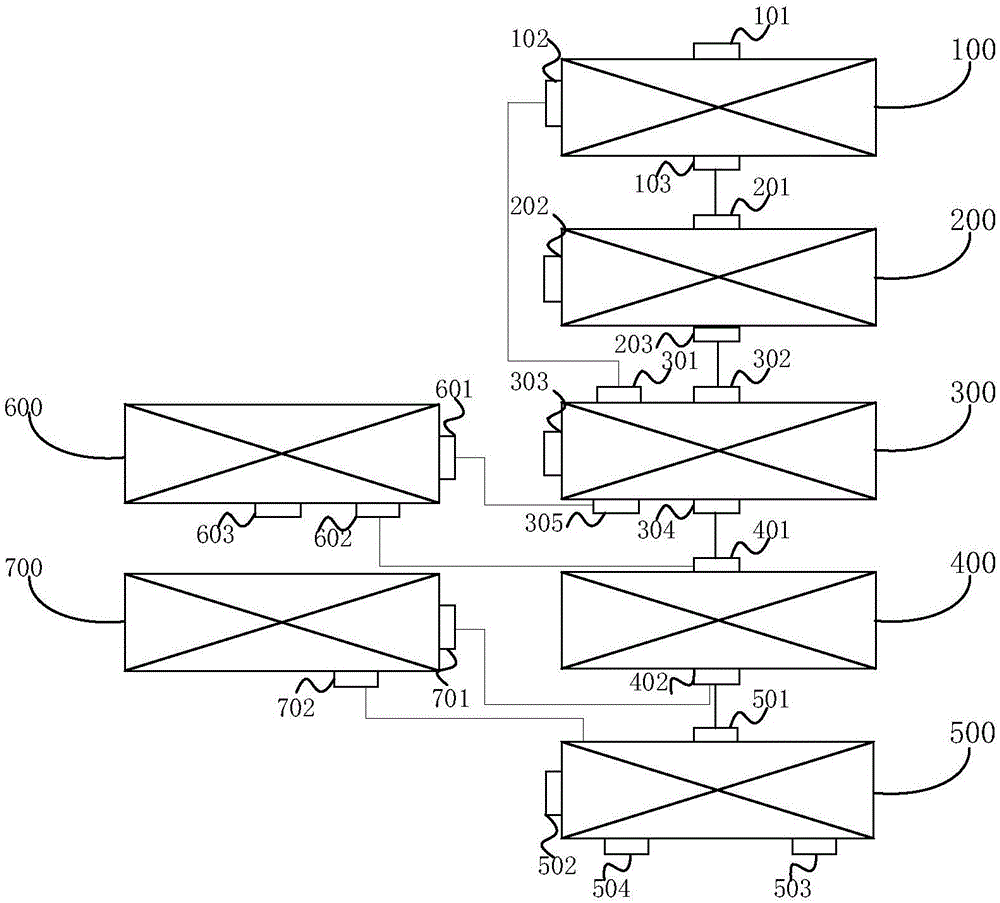

[0102] refer to Figure 13 , supply 100t / d domestic waste to the stockpiling device for stockpiling treatment, and obtain 15t / d landfill leachate, 19t / d inorganic solids and 66t / d pretreated domestic waste; pretreated domestic waste obtained above Supply to the regenerative gas radiant tube rotary hearth furnace for pyrolysis treatment to obtain high-temperature oil gas and garbage charcoal with a temperature of 800 degrees Celsius; supply the above-mentioned garbage charcoal and the above-mentioned garbage leachate to the screw discharger for heat exchange treatment to obtain 7 tons of water vapor with a vaporization temperature of about 110 degrees Celsius, wet garbage charcoal adsorbed with 5 tons of garbage leachate, and 3 tons of leachate mixed with garbage charcoal at about 90 degrees Celsius; the above leachate mixed with garbage charcoal is supplied to the filter device Carry out filtration treatment to obtain filter carbon and filtrate; supply the above-mentioned obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com