Grass-cutting hob, cutter welding tool of grass-cutting hob and manufacturing method of grass-cutting hob

A manufacturing method and welding tooling technology, applied in manufacturing tools, welding equipment, welding equipment and other directions, can solve the problems of poor quality and high cost, and achieve the effects of reducing work difficulty, high positioning accuracy and improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] First make improvements to the mowing reel:

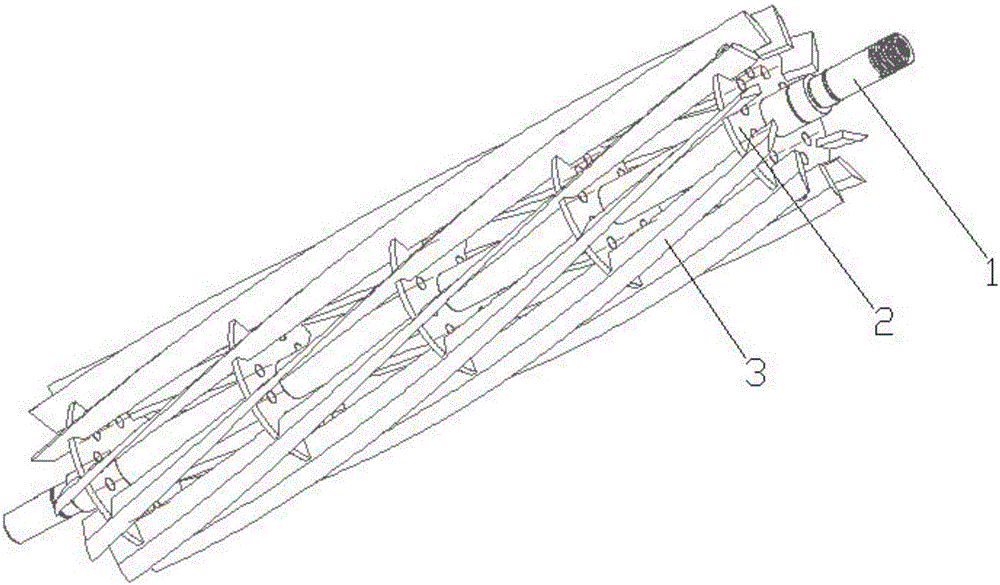

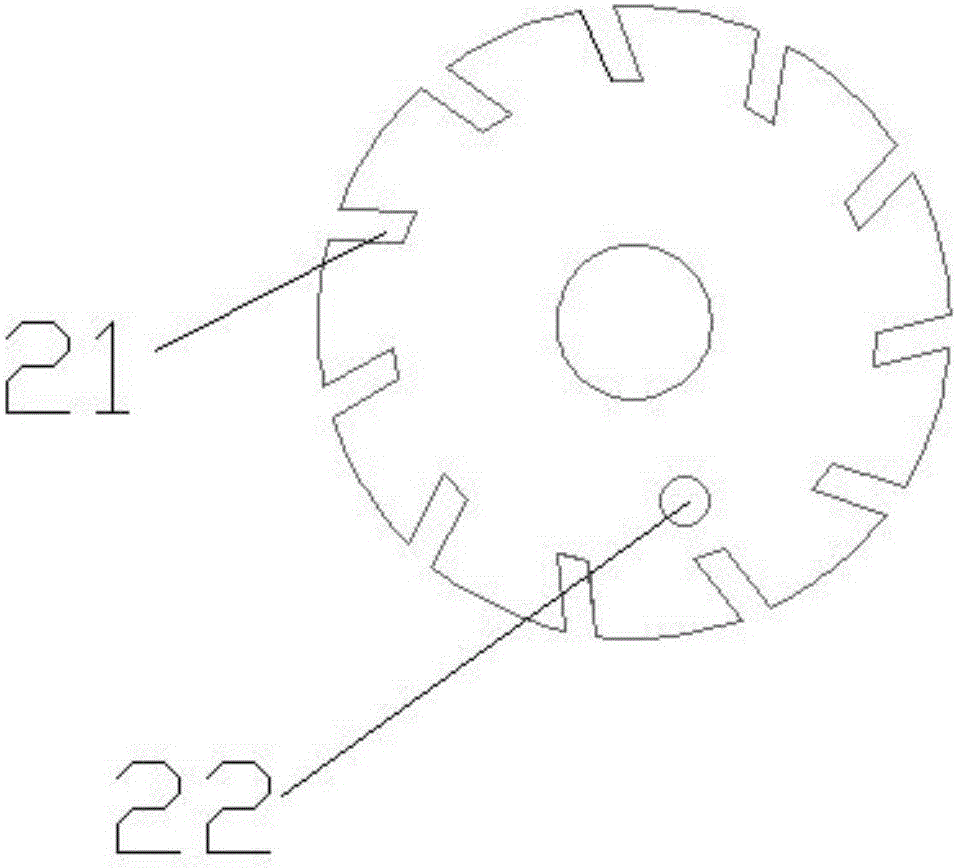

[0047] like figure 1 and figure 2Shown, a kind of mowing hob comprises main shaft 1, cutterhead 2 and blade 3, and described cutterhead 2 quantity is five, is arranged on the main shaft 1 equidistantly; Between five described cutterheads 2 The angle of rotation around the axis of the main shaft 1 differs from one end to the other by an angle of 28°; each cutter head 2 is provided with eleven slots 21, and the eleven slots 21 are formed by the cutter head 2. The center point of the surface is set on the cutter head 2 according to the 360° / 11 array of angles between items, and the number of the blades 3 is eleven; figure 1 As shown, the blade 3 is arranged on two adjacent slots on the five cutterheads whose rotation angles differ by 28°;

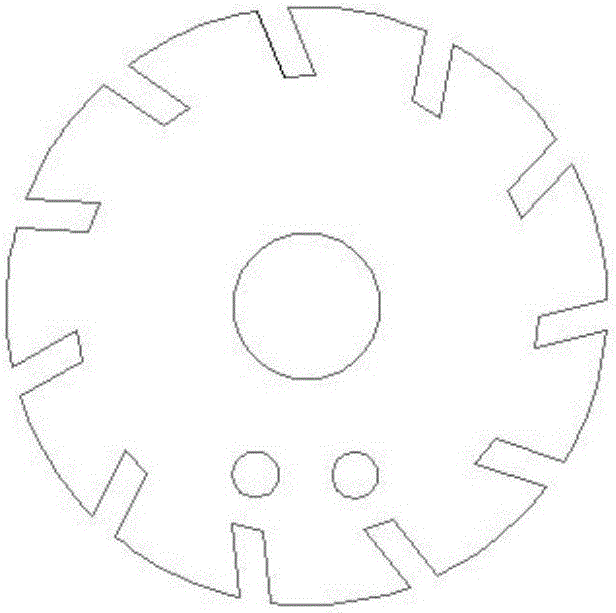

[0048] like figure 2 As shown, the described cutter head 2 is provided with positioning holes 22; the number of positioning holes 22 is 1 in the present embodiment, but as image 3 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com