Resin powder and metal particle separation method and apparatus for achieving resin powder and metal particle separation method

A separation method, a technology of metal particles, applied in the direction of wet separation, solid separation, chemical instruments and methods, etc., can solve the problems of metal separation, waste of non-ferrous metal resources, non-compliance with production regulations, etc., to achieve convenient operation and easy scale The effect of realizing and solving separation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

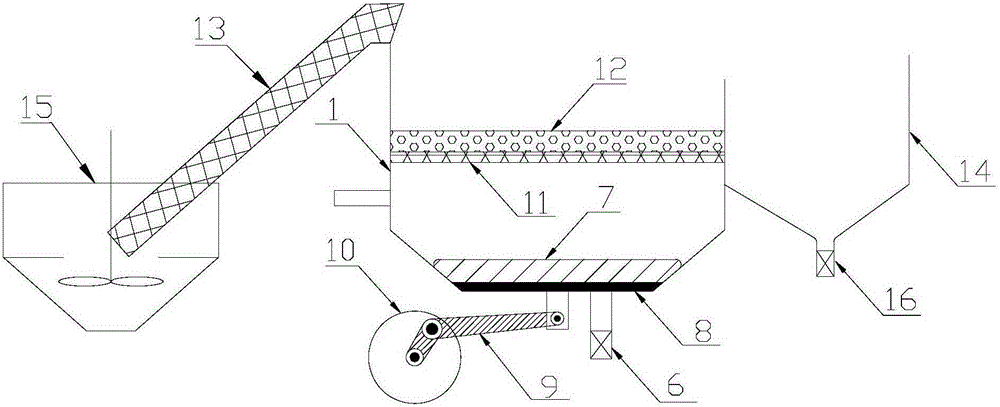

[0025] refer to figure 2 Shown: a kind of device that realizes above-mentioned separation method, comprises water container 1, pulse generator, feeder 13 and resin powder settling tank 14; The bottom of described water container 1 is provided with metal particle discharge opening 6, in The middle part of the water container 1 is provided with an isolation sieve 11, a medium particle bed 12 is laid on the isolation sieve 11, and the resin powder sedimentation tank 14 is provided with a resin powder discharge port 16; the feeder 13 is installed in the water The upper front end of the container 1, the resin powder settling tank 14 is installed at the tail of the water container 1, and the other end of the feeder 13 is equipped with an agitator 15.

[0026] The pulse generator includes a skin bag 7, a swing rod 8, an eccentric connecting rod 9 and an eccentric wheel 10, the skin bag 7 is installed on the bottom of the water container 1, the swing rod 8 is arranged on the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com