A temperature-resistant and salt-resistant ASP flooding produced water degreasing agent and its preparation method

A ternary composite, temperature-resistant and salt-resistant technology, applied in separation methods, mining wastewater treatment, chemical instruments and methods, etc., can solve the problems of difficult regeneration and high cost, and achieve good wetting performance, permeability, and temperature resistance. Superior, simple synthesis process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: Degreaser BE 1 and its preparation method

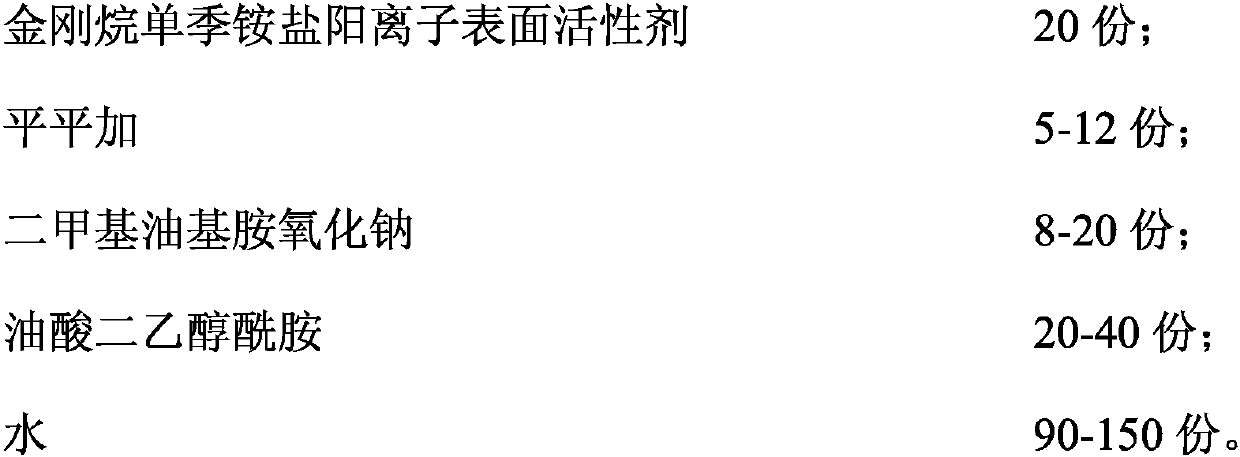

[0029] (1) Degreaser BE 1 The composition and its components are as follows:

[0030]

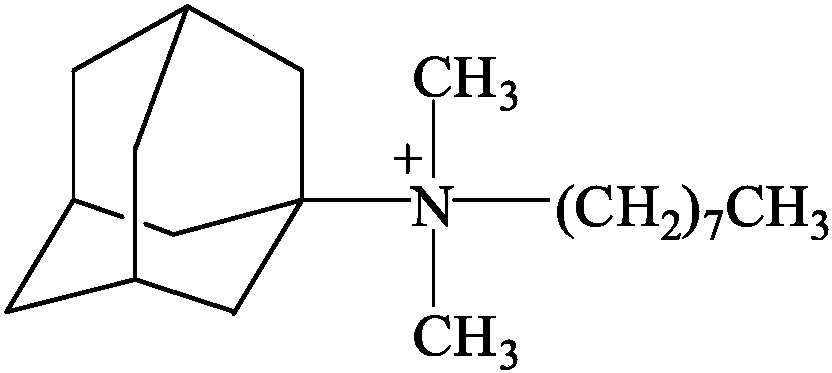

[0031] According to existing literature, the preparation method of described adamantane monoquaternary ammonium salt cationic surfactant is as follows:

[0032]

[0033] (2) Degreaser BE 1 The preparation method is as follows:

[0034] ① Mix 20 parts of adamantane monoquaternary ammonium salt cationic surfactant and 5 parts of Pingpingjia into the first beaker, add 30 parts of water, and heat while stirring. The stirring rate is 270ppm, and the heating temperature is 50°C. The heating time is 20min, and after the heating time is over, the temperature is naturally cooled to room temperature to obtain the mixed solution A;

[0035] ②Mix 8 parts of sodium dimethyl oleylamine oxide and 20 parts of oleic acid diethanolamide into the second beaker, add 30 parts of water, heat while stirring, the stirring rate is 500ppm, a...

Embodiment 2

[0037] Embodiment 2: Degreaser BE 2 and its preparation method

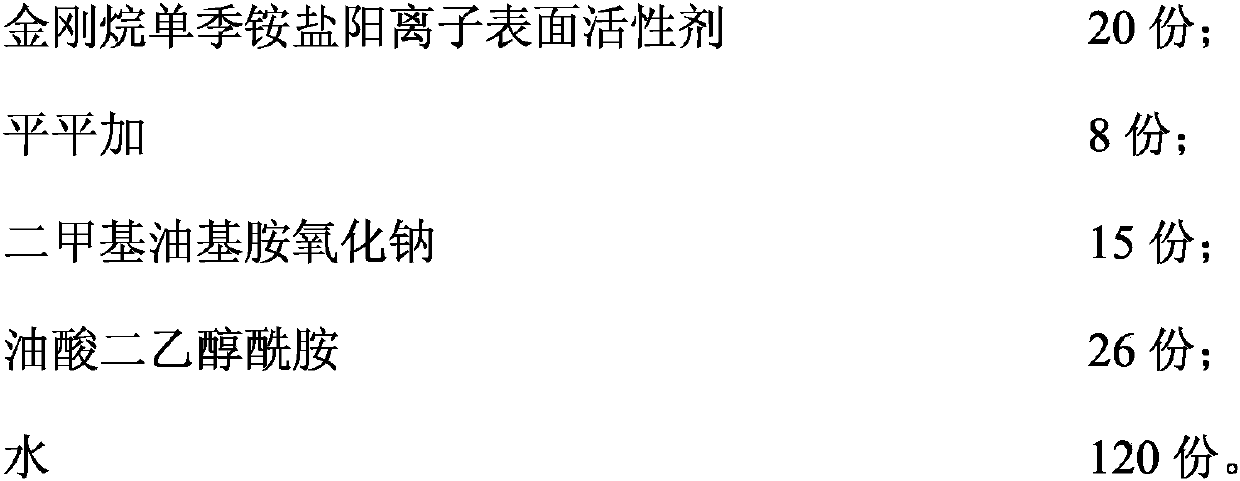

[0038] (1) Degreaser BE 2 The composition and its components are as follows:

[0039]

[0040] According to existing literature, the preparation method of described adamantane monoquaternary ammonium salt cationic surfactant is as follows:

[0041]

[0042] (2) Degreaser BE 2 The preparation method is as follows:

[0043] ① Mix 20 parts of adamantane monoquaternary ammonium salt cationic surfactant and 8 parts of Pingpingjia into the first beaker, add 40 parts of water, and heat while stirring. The stirring rate is 200ppm, and the heating temperature is 53°C. The heating time is 25min, and after the heating time is over, the temperature is naturally lowered to room temperature to obtain the mixed solution A;

[0044] ② Mix 15 parts of sodium dimethyl oleylamine oxide and 26 parts of oleic acid diethanolamide into the second beaker, add 40 parts of water, heat while stirring, the stirring rate is 530ppm, ...

Embodiment 3

[0046] Embodiment 3: Degreaser BE 3 and its preparation method

[0047] (1) Degreaser BE 3 The composition and its components are as follows:

[0048]

[0049] According to existing literature, the preparation method of described adamantane monoquaternary ammonium salt cationic surfactant is as follows:

[0050]

[0051] (2) Degreaser BE 3 The preparation method is as follows:

[0052] ① Mix 20 parts of adamantane monoquaternary ammonium salt cationic surfactant and 10 parts of Pingpingjia into the first beaker, add 45 parts of water, and heat while stirring. The stirring rate is 240ppm, and the heating temperature is 57°C. The heating time is 26min, and after the heating time is over, the temperature is naturally cooled to room temperature to obtain the mixed solution A;

[0053] ② Mix 18 parts of sodium dimethyl oleylamine oxide and 35 parts of oleic acid diethanolamide into the second beaker, add 45 parts of water, heat while stirring, the stirring rate is 550ppm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| oil removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com