Method of using nickel alloy union squirrel cage air-cooling water-cooling motor system to treat kitchen sewage

A nickel alloy and squirrel cage technology is applied in the field of treating kitchen sewage with an alloy union squirrel cage air-cooled cooling motor system, which can solve the problems such as the inability to effectively control the water discharge in the kitchen, high housing prices, and difficult sewage treatment methods. Achieve the effect of obvious energy saving, cost reduction and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

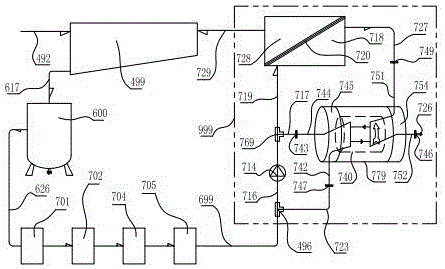

[0062] In conjunction with the accompanying drawings and embodiments, the structure and working principle of the present invention and its application in the kitchen waste sewage treatment process are further elaborated:

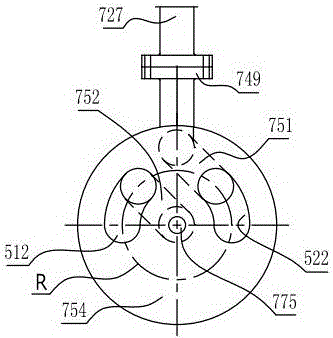

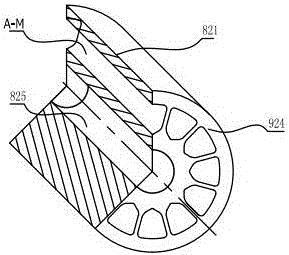

[0063] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 11 , Figure 32 with Figure 33 Among them, the nickel alloy union cage air-cooled water-cooled motor system is used to treat kitchen sewage. The nickel alloy union cage air-cooled water-cooled motor system includes a kitchen sink 499, a three-stage suit grille 600, and degreasing equipment 701 , centrifugal equipment 702, salt-tolerant anaerobic biofilm reactor 704, salt-tolerant aerobic biofilm reactor 705 and union energy recovery reverse osmosis system 999, as improvements:

[0064] The union energy recovery reverse osmosis system 999 includes a reverse osmosis membrane 720, a high-pressure tee 769, a high-pressure injection ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com