Ceramic tile with color-assisting flower glaze layer and preparation method thereof

A technology for ceramic tiles and colored flowers, which is applied in the field of ceramic tiles with a color-aided flower glaze layer and the field of preparation thereof, and achieves the effects of clear boundary texture, improved color strength, and reduced production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

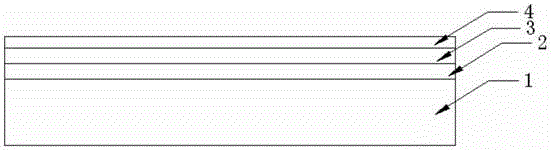

[0034] Refer to attached figure 1 , the present embodiment provides a ceramic tile with a whitening layer, which comprises from bottom to top: a green body layer 1, a glaze layer 2, a whitening layer 3 and a printed pattern layer 4, and the whitening layer 3 is made by screen printing Formed by whitening glaze, the thickness of the whitening layer 3 is 0.2-1.2mm.

[0035] Its preparation method is as follows:

[0036] Step 1) Selecting known ceramic body powder to be stamped into brick adobe;

[0037] Step 2) applying a known top glaze on the surface of the green body by glazing to form a top glaze layer;

[0038] Step 3) Printing a whitening glaze on the surface glaze layer by screen printing to form a whitening layer;

[0039] Step 4) adopting known printing methods to form a printing layer on the whitening layer;

[0040] Step 5) go into kiln and burn;

[0041] Step 6) Polishing and edging the fired body to obtain a ceramic tile product.

[0042] Wherein, the green bo...

Embodiment 2

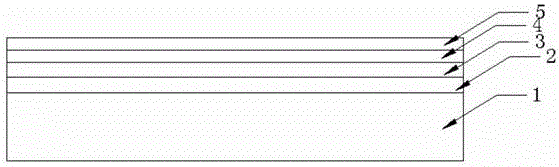

[0049] Refer to attached figure 2 , a kind of ceramic tile, it comprises from bottom to top: green body layer 1, surface glaze layer 2, whitening layer 3, printing pattern layer 4 and powdery glaze layer 5.

[0050] Here, the powder-enhancing glaze forming the powder-enhancing glaze layer 5 is calculated in parts by mass, and includes the following components: high-boron calcium transparent frit: 12 parts, 0.1-10 parts of complementary color pigments, carboxymethyl cellulose: 1.3 parts , ethylene glycol: 45 parts, water: 40 parts;

[0051] The chemical composition of the high boron calcium transparent frit is calculated in parts by weight of oxides, including the following components: Na 2 O: 6 parts, CaO: 12 parts, ZnO: 7 parts, B 2 o 3 : 8 servings, Al 2 o 3 :3 parts, SiO 2 :54 copies;

[0052] The complementary color pigment is one or more combinations of known ceramic glaze pigments.

[0053] For the preparation method, on the basis of Example 1, the step of apply...

Embodiment 3

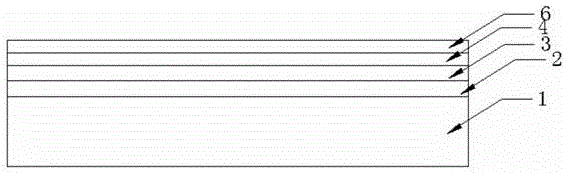

[0057] Refer to attached image 3 , a ceramic tile, which comprises from bottom to top: a body layer 1, a glaze layer 2, a whitening layer 3, a printed pattern layer 4 and a color-helping glaze layer 6.

[0058] Here, the color-helping glaze forming the color-helping glaze layer 6 is calculated in parts by mass, and includes the following components: 100 parts of high-zinc frit, 130 parts of printing paste, 0.3 parts of sodium tripolyphosphate, and 40 parts of water share;

[0059] The chemical components of the high-zinc frit are calculated in parts by weight of oxides, and include the following components:

[0060] SiO 2 : 53 parts, ZnO: 21 parts, K 2 O: 4 parts, Al 2 o 3 : 7 parts, MgO: 3 parts, CaO: 3.5 parts.

[0061] It should be noted that the inner glaze layer 2 and the whitening layer 3 may not be applied here, and of course the effect of the obtained ceramic tile product will decrease correspondingly. Of course, it is also possible to also include the powder-e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com