Cement paste for buildings with energy conservation, lightweight, insulation and crack resistance

A building energy-saving and lightweight technology, applied in the field of building materials and high-performance cement materials, to achieve the effect of reducing cement density, low water absorption and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

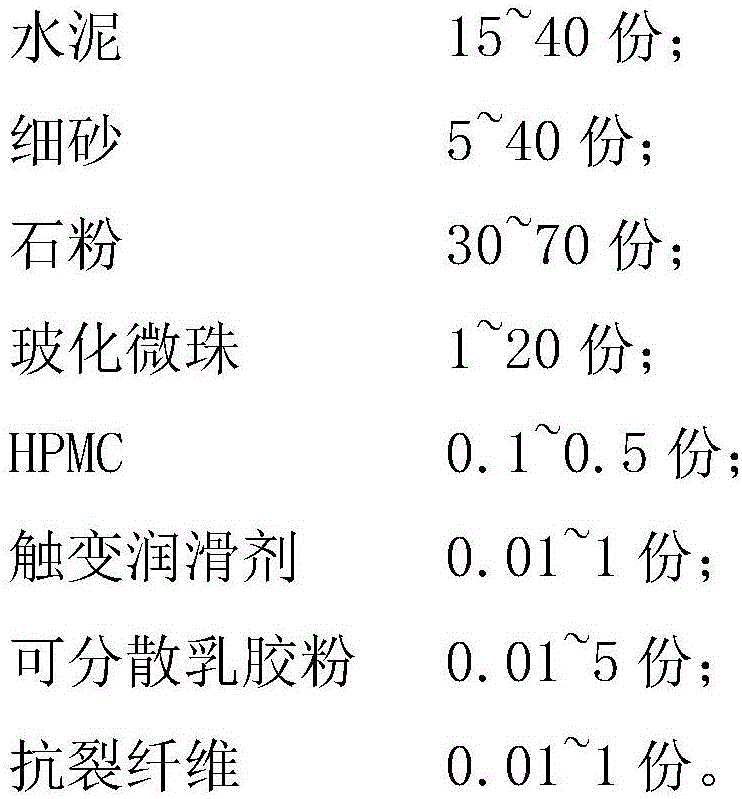

[0034] Building energy-saving lightweight thermal insulation and anti-cracking cement, the components are as follows in parts by weight:

[0035]

[0036] Manual scraping or mechanical spraying can be used. The average construction thickness is 5-8mm.

Embodiment 2

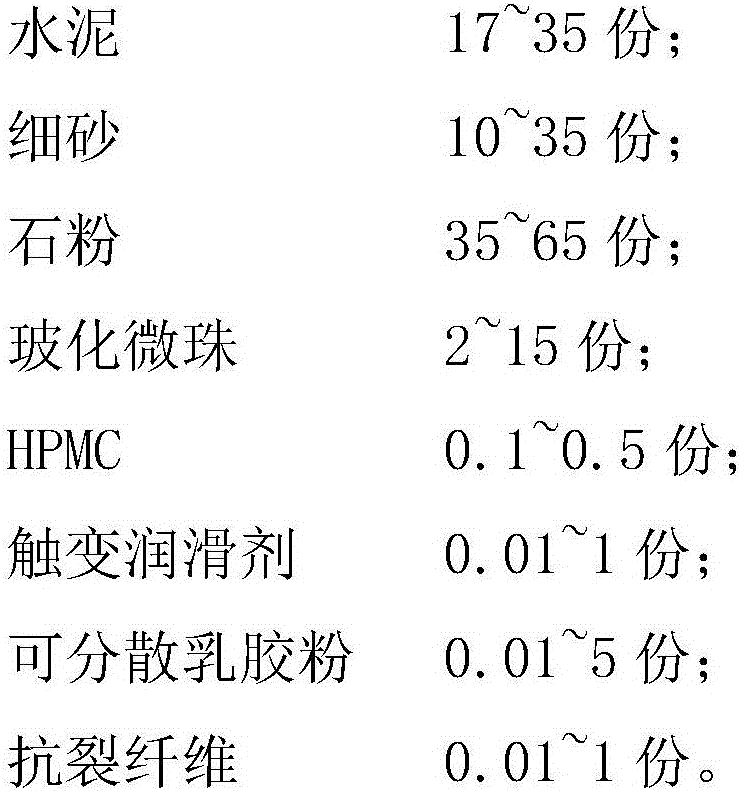

[0038] Building energy-saving lightweight thermal insulation and anti-cracking cement, the components are as follows in parts by weight:

[0039]

[0040] For construction methods and requirements, refer to Embodiment 1.

Embodiment 3

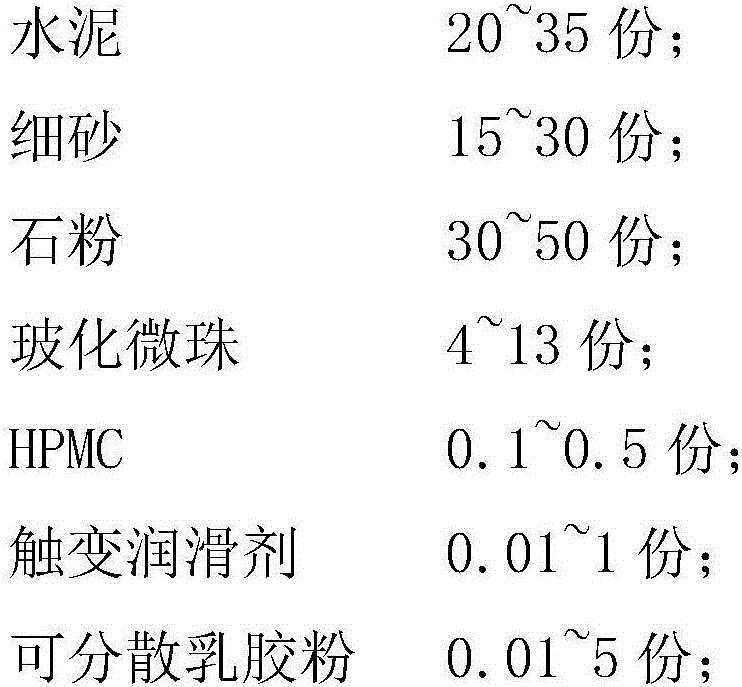

[0042] Building energy-saving lightweight thermal insulation and anti-cracking cement, the components are as follows in parts by weight:

[0043]

[0044] For construction methods and requirements, refer to Embodiment 1.

[0045] The construction method of the present invention can be manually scraped or mechanically sprayed. Ordinary mortar can only be constructed manually by layered scraping; When the next layer of construction is carried out, it is necessary to wait for the mortar of this layer to reach a certain degree of dryness; the use of mechanical spraying can also save labor and shorten the construction period; the average construction thickness is 5-8mm, and the traditional construction thickness is 15-20mm. It is equivalent to increasing the usable area of the house. Every meter of wall increases the plane usable area by about 0.010-0.015㎡; the dry powder density is 800-1000kg / m 3 , the traditional dry-mixed mortar and wet-mixed mortar are all converted into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com