Micro-fluidic gel gas-liquid interface flue gas exposing device

A gas-liquid interface and microfluidic technology, which is applied in enzymology/microbiology devices, biochemical cleaning devices, methods for supporting/immobilizing microorganisms, etc., can solve the problems of bulky and expensive exposure devices, which limit the promotion and popularization of devices and other issues to achieve the effect of maintaining stability and avoiding direct impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0024] 1. The production process of the chip platform

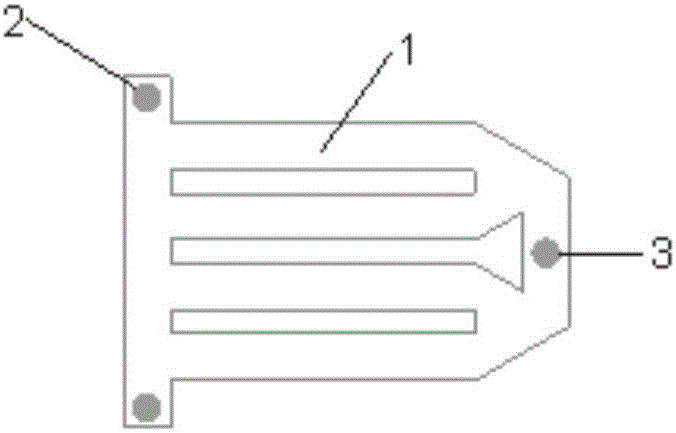

[0025] 1. Upper chip: Spread uncured polydimethylsiloxane (PDMS prepolymer: curing agent = 10:1) on the upper chip template, vacuum for 10 minutes to remove air bubbles, and heat on a heating platform at 70°C Cured for 45 minutes, peeled off, and punched at the designated position to get the upper chip, see figure 1 .

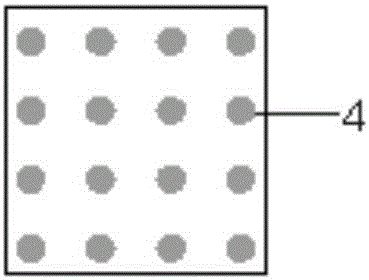

[0026] 2. Intermediate layer chip: Use a laser engraving machine to engrave a 4*4 array of hole-like structures on a 0.5mm thick organic plastic plate with a pore size of 1mm, which can be used for cell loading, see figure 2 .

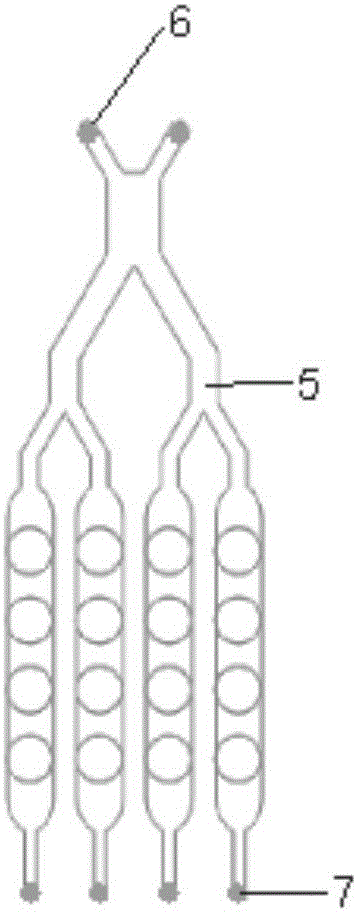

[0027] 3. Lower chip: Spread uncured polydimethylsiloxane (PDMS prepolymer: curing agent = 10:1) on the lower chip template, vacuum for 10 minutes to remove air bubbles, and heat on a heating platform at 70°C Cured for 45 minutes, peeled off, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com