Trigona rearing box and application method

A technology of breeding boxes and stinging bees, which is applied to the breeding boxes and application fields of stingless bees, can solve the problems of inconvenient inspection and feeding management, large damage to the stinging bees, and reducing the amount of honey collected, so as to achieve rapid manual separation of bees and ensure normal operation. Survival, the effect of reducing labor consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Including the box bottom 1, the top of the box bottom 1 is provided with a powder storage box 5, and a plurality of first ventilation holes 4 are opened on the box bottom 1, and the inside of the powder storage box 5 is provided with a first inner box layer 8, and the inner wall of the powder storage box 5 and The first insulation layer 7 is filled between the outer walls of the first inner box layer 8, and the inner wall of the first inner box layer 8 is fixedly connected with a plurality of ring-shaped powder storage plates 9, and the diameters of the plurality of powder storage plates 9 are different. The material of a thermal insulation layer 7 is the mixture of vermiculite, sawdust and cement mixed in proportion to ensure that the inside of the powder storage box 5 is in a constant temperature state. The bees provide sufficient powder storage space, which is convenient and hygienic;

Embodiment 2

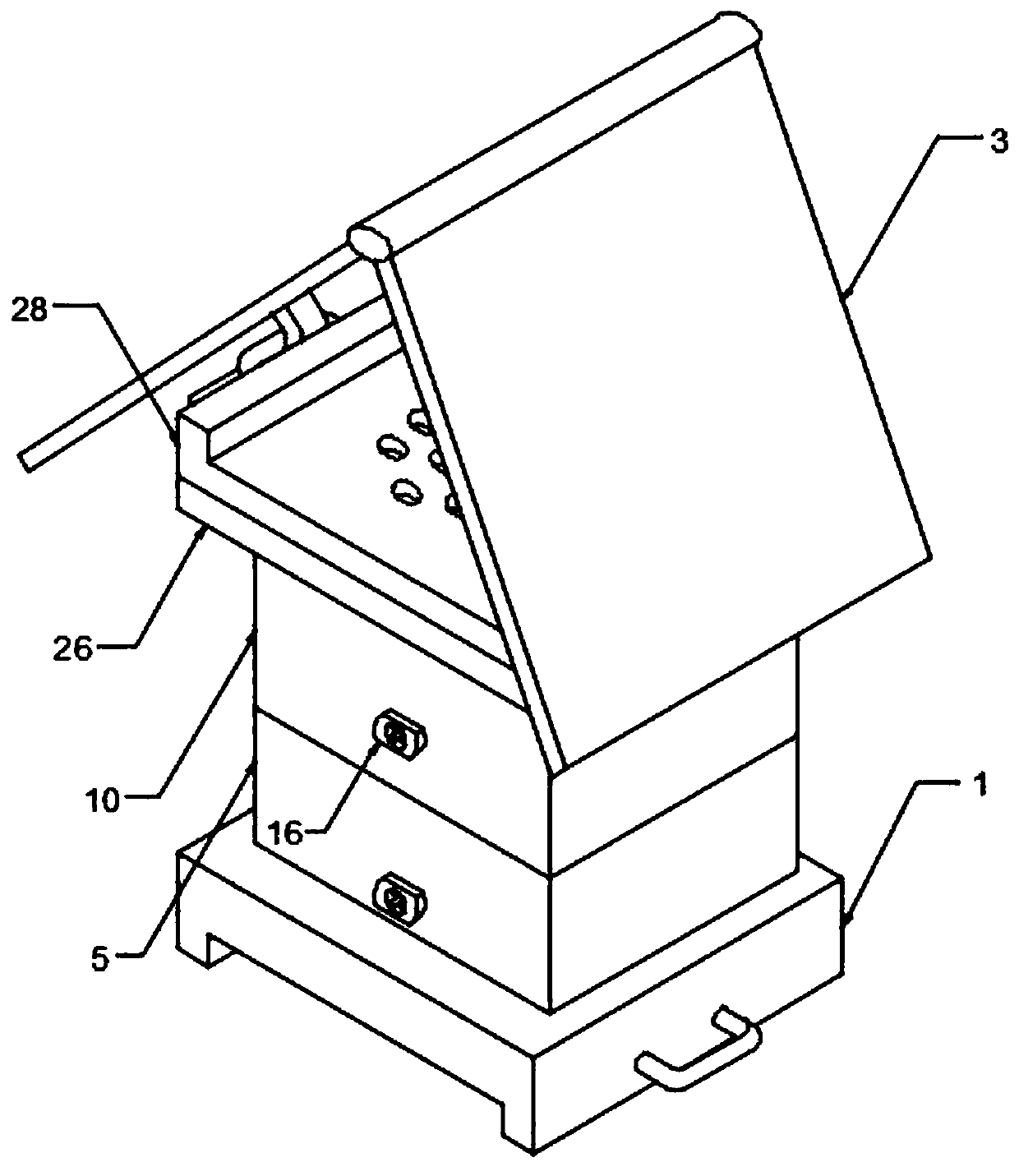

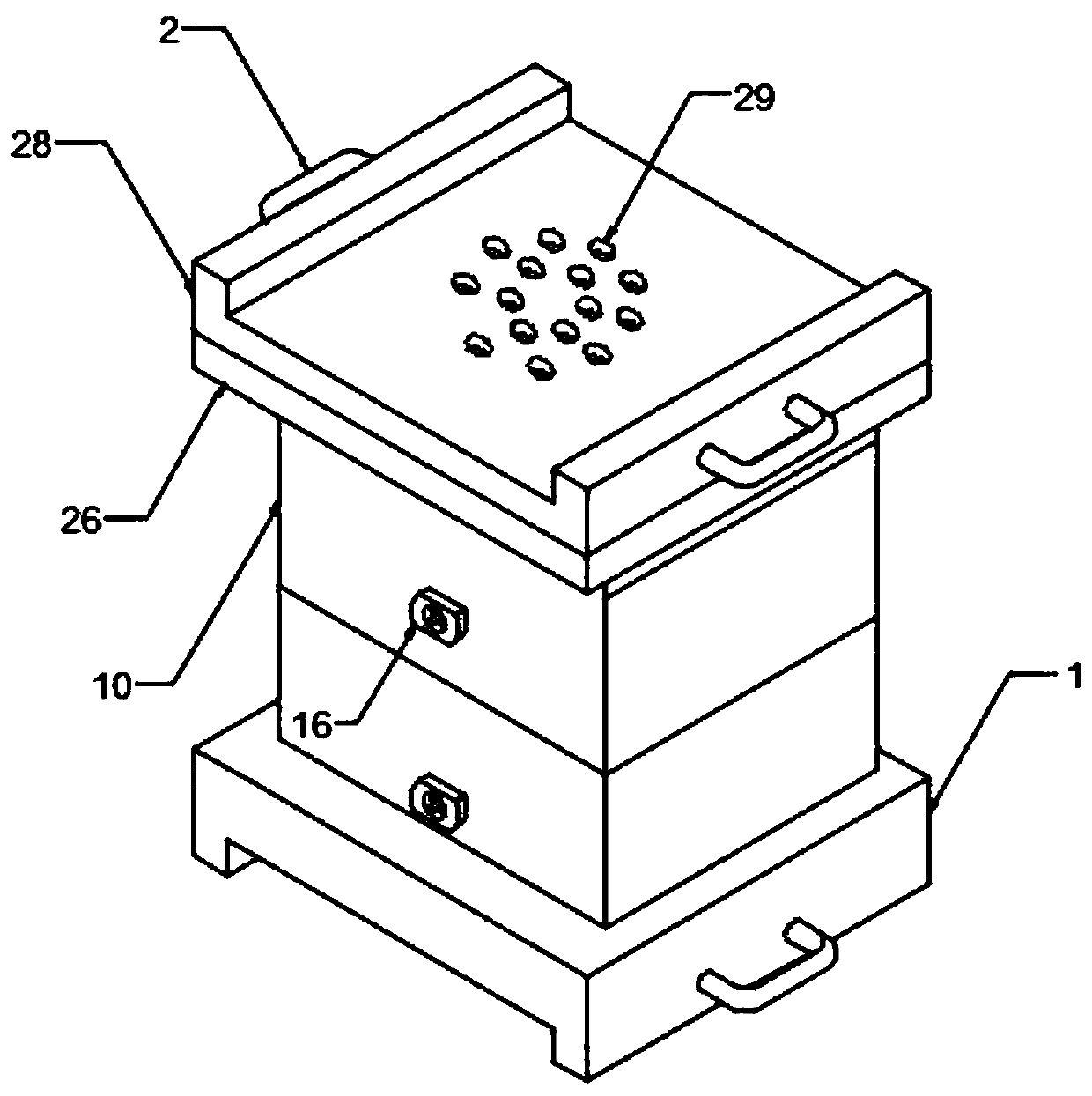

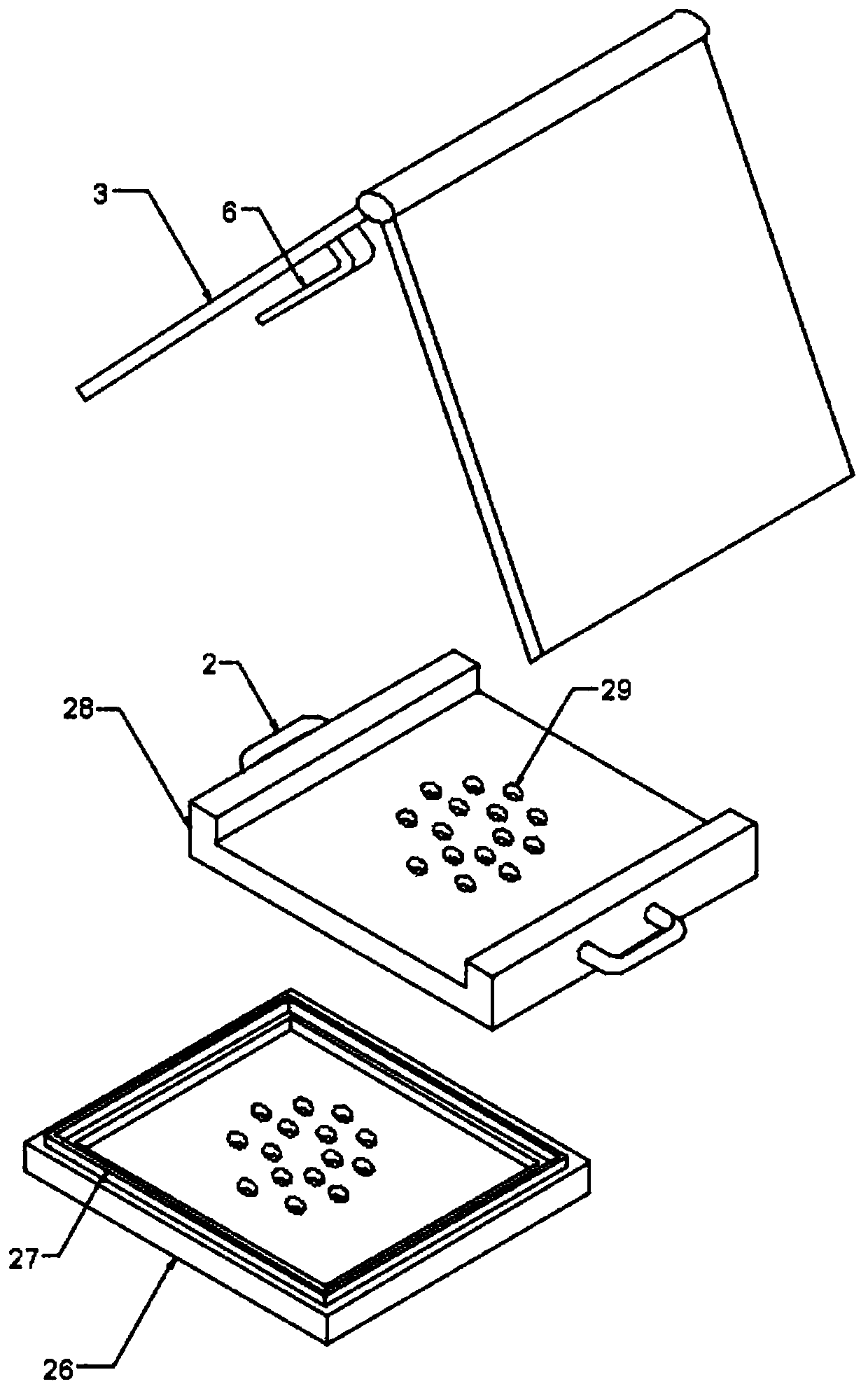

[0045] Further with respect to embodiment 1: the top of the powder storage box 5 is provided with a breeding box 10, and the inside of the breeding box 10 is provided with a second inner box layer 12, between the inwall of the breeding box 10 and the outer wall of the second inner box layer 12 Filled with the second insulation layer 11, the inner wall of the second inner box layer 12 is fixedly connected with a plurality of annular convex plates 13, and the outer wall of the annular convex plate 13 is provided with a plurality of honeycombs 14, and the front of the powder storage box 5 and the breeding box 10 All have nest door 15, and the inside of nest door 15 is provided with nest door plug 16, and the middle part of nest door plug 16 is provided with opening 17, and one end of opening 17 is embedded with lifting bar 18, and the other end of opening 17 is embedded with Be provided with screen cloth 19, the material of the second insulation layer 11 is the mixture of vermicul...

Embodiment 3

[0047] Further with respect to embodiment 2: the top of the breeding box 10 is provided with a honey storage box 20, the inner wall of the honey storage box 20 is clamped with a plastic honey box 21, and the inside of the plastic honey box 21 is embedded with a plurality of independent hemispherical Honeypot 22, the central position of plastic honey box 21 is provided with bee channel 23, and the top and bottom of honey storage box 20 are all provided with plastic grille 24, offers a plurality of air holes 25 on plastic grille sheet 24, plastic grille sheet The middle part of 24 is provided with the through hole relative to honeybee passage 23 positions, and the size of through hole is identical with the size of honeybee passage 23, and honeybee passage 23 is convenient to the stingless bee to pass through, and the size of plastic grid sheet 24 is identical with the size of plastic honey box 21 , the plastic honey box 21 is used to collect honey, which is clean and hygienic and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com