A method for cultivating microalgae at high density using municipal sewage in a membrane photobioreactor

A photobioreactor and photobioreaction technology, applied in the direction of unicellular algae, bacteria, etc., can solve the problems of low nitrogen and phosphorus content, the water quality of the effluent does not meet the discharge requirements, and it is difficult to maintain high-density cultivation of algal cells, etc. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

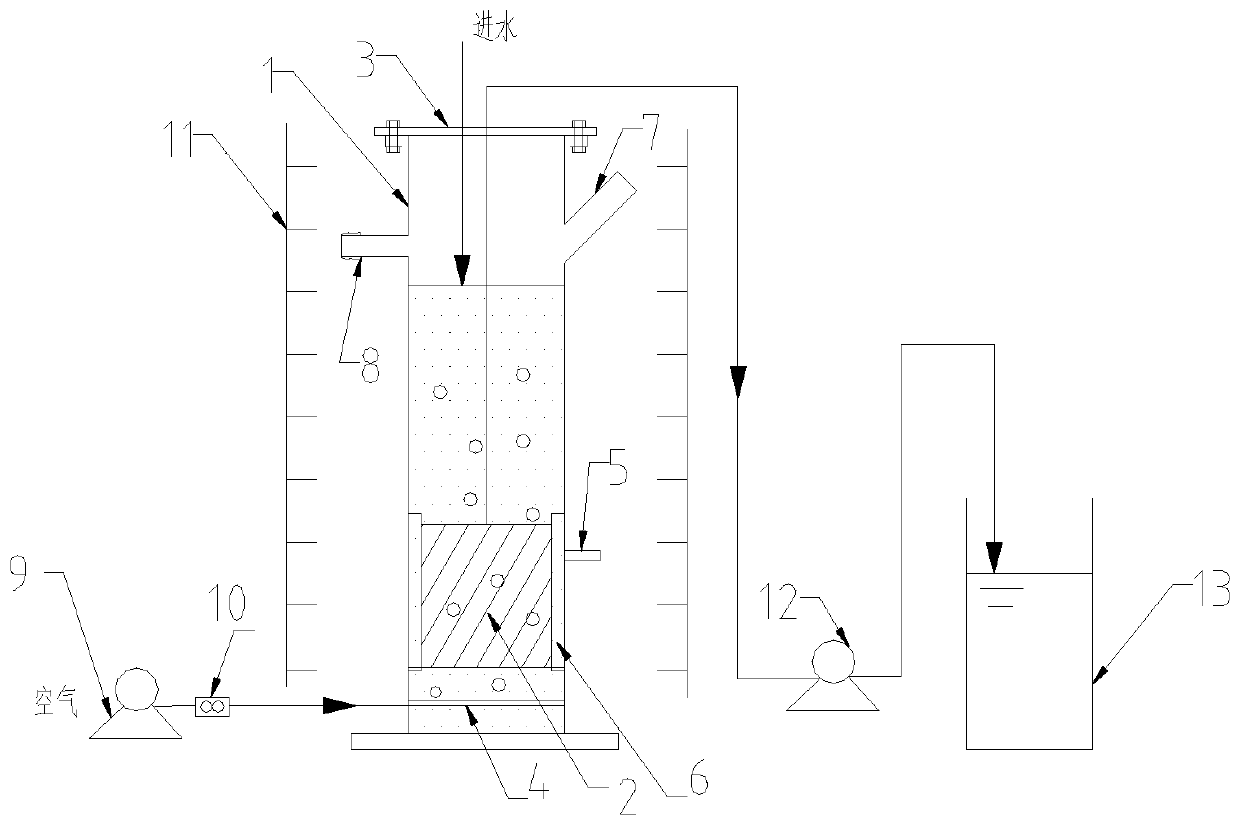

[0042] The membrane photobioreactor structure that the present invention uses is as figure 1 Shown (with CN 204727884U in figure 1 The reactors are basically the same).

[0043]The membrane photobioreactor comprises a photobioreaction device 1, an illumination device 11, a gas supply device 9, a membrane permeation device 2, and a permeate collection device 13; the illumination device 11 is located outside the photobioreaction device 1; the light The upper part of the bioreactor 1 is provided with a sample inlet 7 and a gas outlet 8, the lower part is provided with a sample outlet 5 and a membrane module slot 6, and the bottom is provided with a microporous aeration tube 4; the gas supply device 9 communicates with light through a pipeline. The microporous aeration pipe 4 at the bottom of the bioreactor 1 is connected; the membrane permeation device 2 is installed in the photobioreaction device 1; the membrane permeation device 2 and the permeate collection device 13 are conn...

Embodiment 2

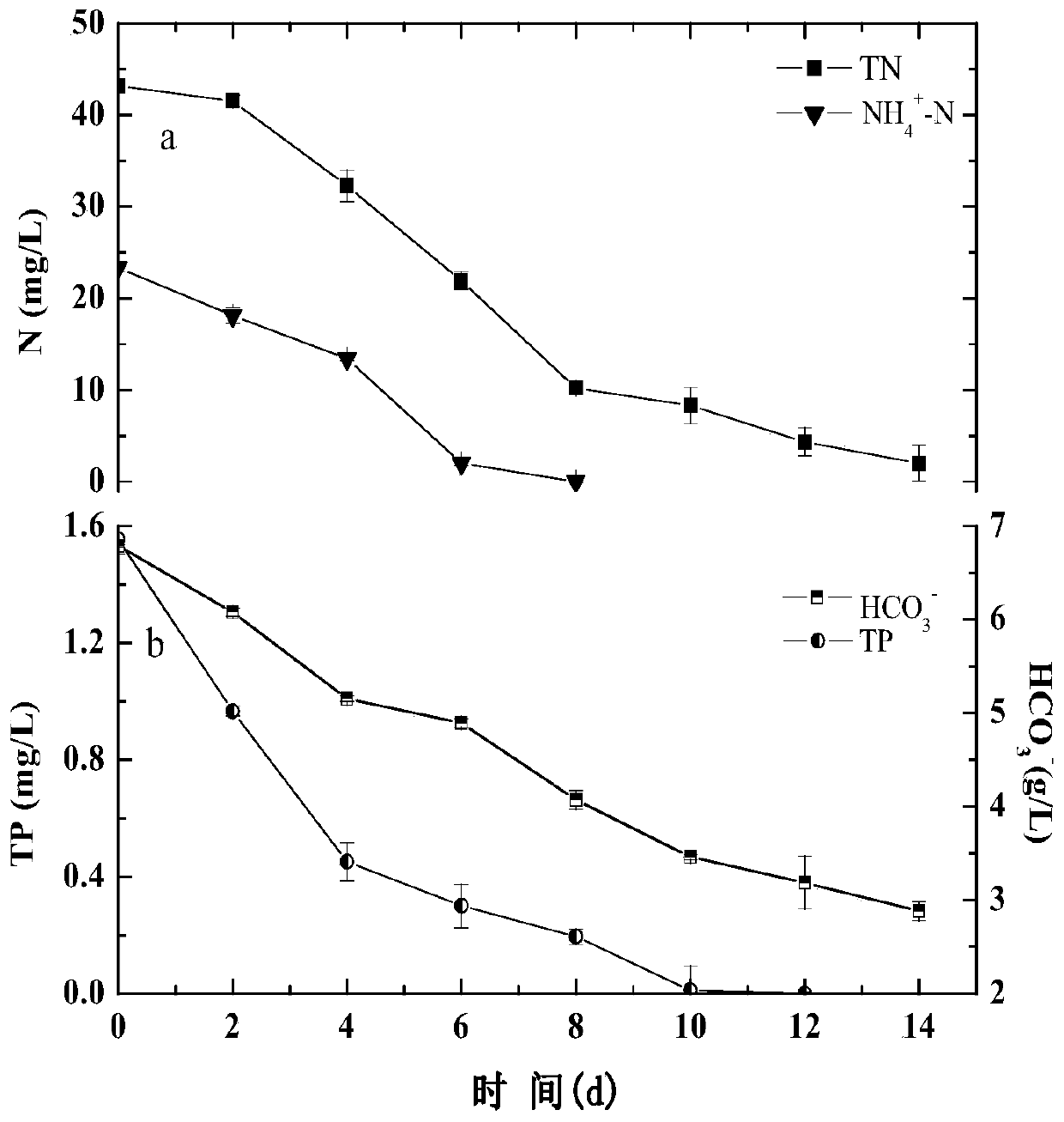

[0045] Example 2: Effect of Carbon Source Addition on the Growth of Spirulina and the Removal of Nutrients in Sewage

[0046] (1) The effect of carbon source addition on the biomass of Spirulina

[0047] The Spirulina platensis used in this example was purchased from the freshwater algae stock of the Institute of Hydrobiology, Chinese Academy of Sciences, numbered FACHB-901; the municipal sewage used was taken from the effluent of the primary sedimentation tank of Wuxi Taihu New Town Wastewater Treatment Plant, and the water quality indicators are shown in Table 1 shown.

[0048] Table 1 Municipal sewage water quality

[0049]

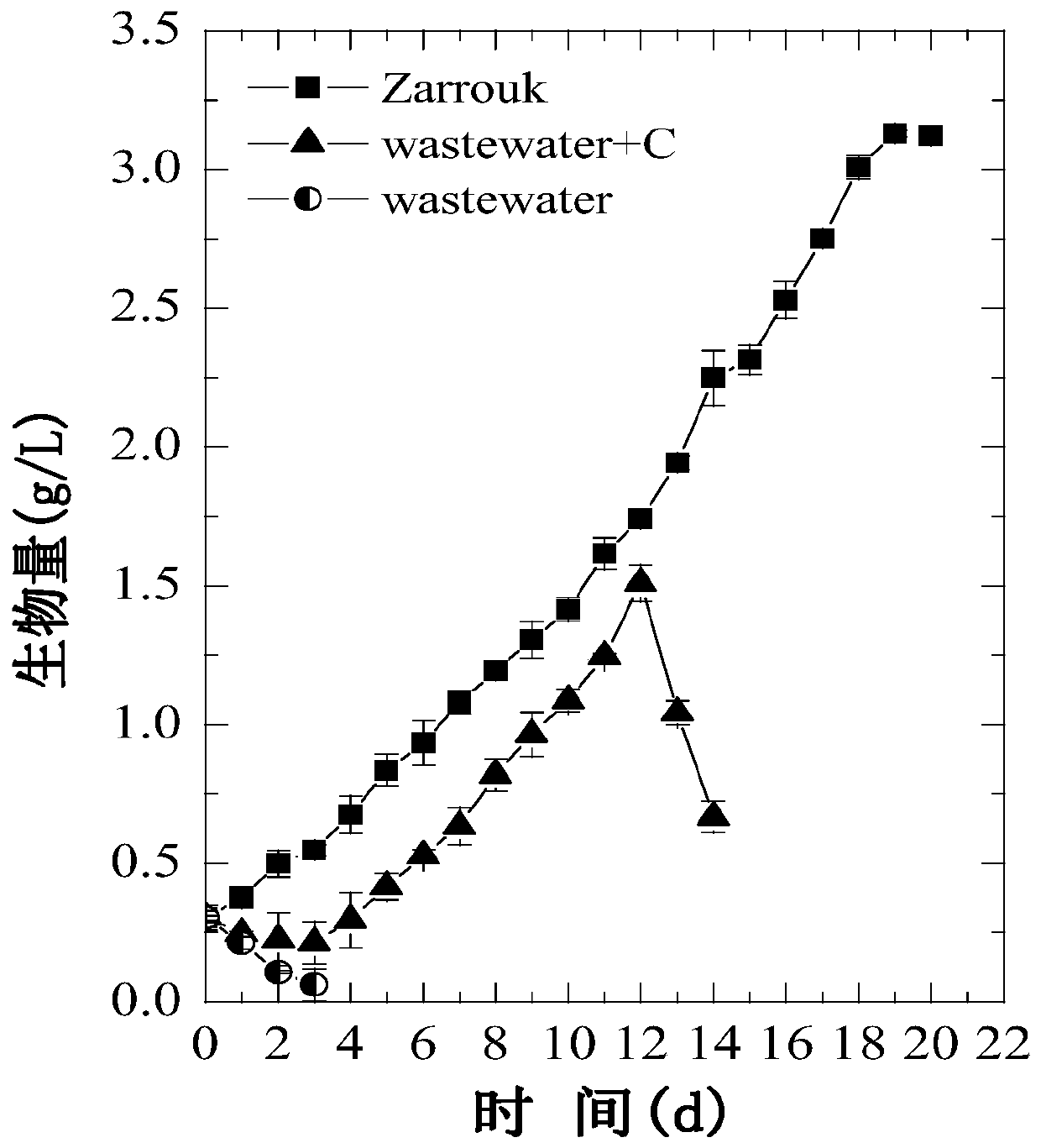

[0050] Changes in the biomass of microalgae during the process of cultivating microalgae with sewage figure 2 shown. figure 2 The results showed that the biomass of Spirulina continued to decrease in the raw sewage water without adding carbon source, and it grew to death on the third day, indicating that the raw sewage water could not be direct...

Embodiment 3

[0056] Embodiment 3: Determination of suitable hydraulic retention time in MPBR semi-continuous culture process

[0057] Inoculate Spirulina to add 1g / L NaHCO 3 In municipal sewage (see Table 1 for water quality indicators), when the density of MPBR algae reaches 1g / L-1.2g / L, semi-continuous culture is carried out, and the initial HRT is set to 7d. According to the daily growth of microalgae and the NH in sewage 4 + The removal of -N gradually reduces the HRT to 1.5d, maintaining the stable operation of the reactor. Among them, the inoculation density of algae cells is 0.5g / L, cultivated under the conditions of light intensity 3000Lux, temperature (30±1)°C, light-dark ratio 16 / 8.

[0058] (1) Changes of microalgae biomass, pH value and ammonia nitrogen in effluent under different HRT

[0059] The biomass changes of Spirulina in MPBR under different HRT as Figure 4 As shown, semi-continuous culture was started when the biomass reached 1.105g / L. When the HRT is 7d to 2d (t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com