A bake-hardening high-strength steel and its manufacturing method

A technology of bake hardening and manufacturing method, applied in the field of steel and its manufacturing, can solve the problems such as difficulty in attaining high strength, increase in production cost, influence on the surface quality of galvanized products, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1-A6 and comparative example B1-B2

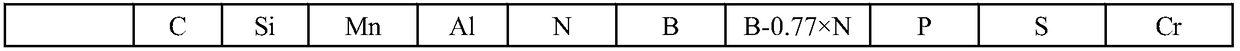

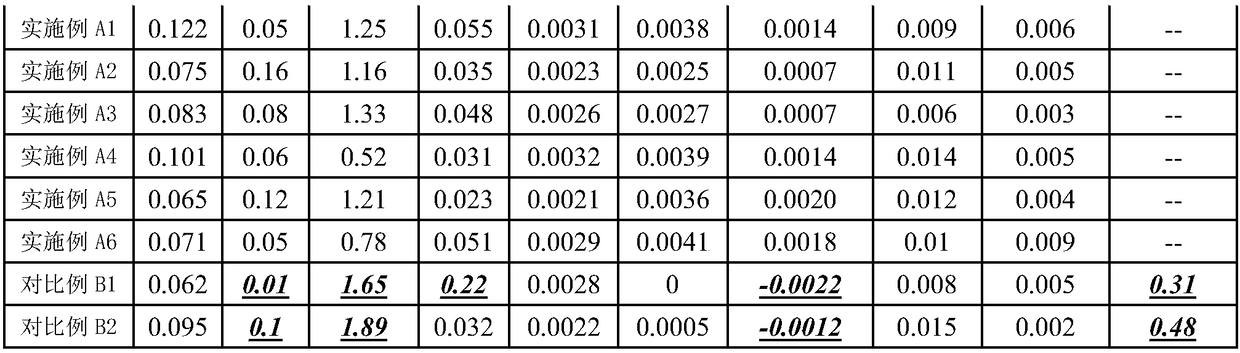

[0048] The manufacturing method of the bake-hardening high-strength steel of the above-mentioned embodiments A1-A6 and the conventional bake-hardening steel of the comparative examples B1-B2 is obtained by the following steps (see Table 2 for the specific process parameters of each embodiment and comparative example)

[0049] (1) smelting: control the mass percent of the chemical elements of Examples A1-A6 and Comparative Examples B1-B2 as shown in Table 1;

[0050] (2) Hot rolling: the heating temperature is controlled to be greater than 1180°C, the final rolling temperature is above Ar3, and the coiling temperature is less than 650°C;

[0051] (3) pickling;

[0052] (4) Cold rolling: control the cold rolling deformation to be greater than 50%;

[0053] (5) Continuous annealing: the annealing temperature is controlled at 750-850°C, the annealing cooling rate is 50-200°C / s, the overaging temperature of continuous annealing is less than 300°C, and the annealing time is 40-100s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com