A real-time monitoring device for pavement paving thickness of balance beam type

A technology for real-time monitoring and balancing beams, applied in the direction of roads, roads, road repair, etc., can solve the problems of manual measurement, cumbersome process, and inability to monitor the thickness of paving in real time, so as to ensure measurement accuracy, reduce human errors, and facilitate feedback. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below in conjunction with accompanying drawing, the present invention will be further described:

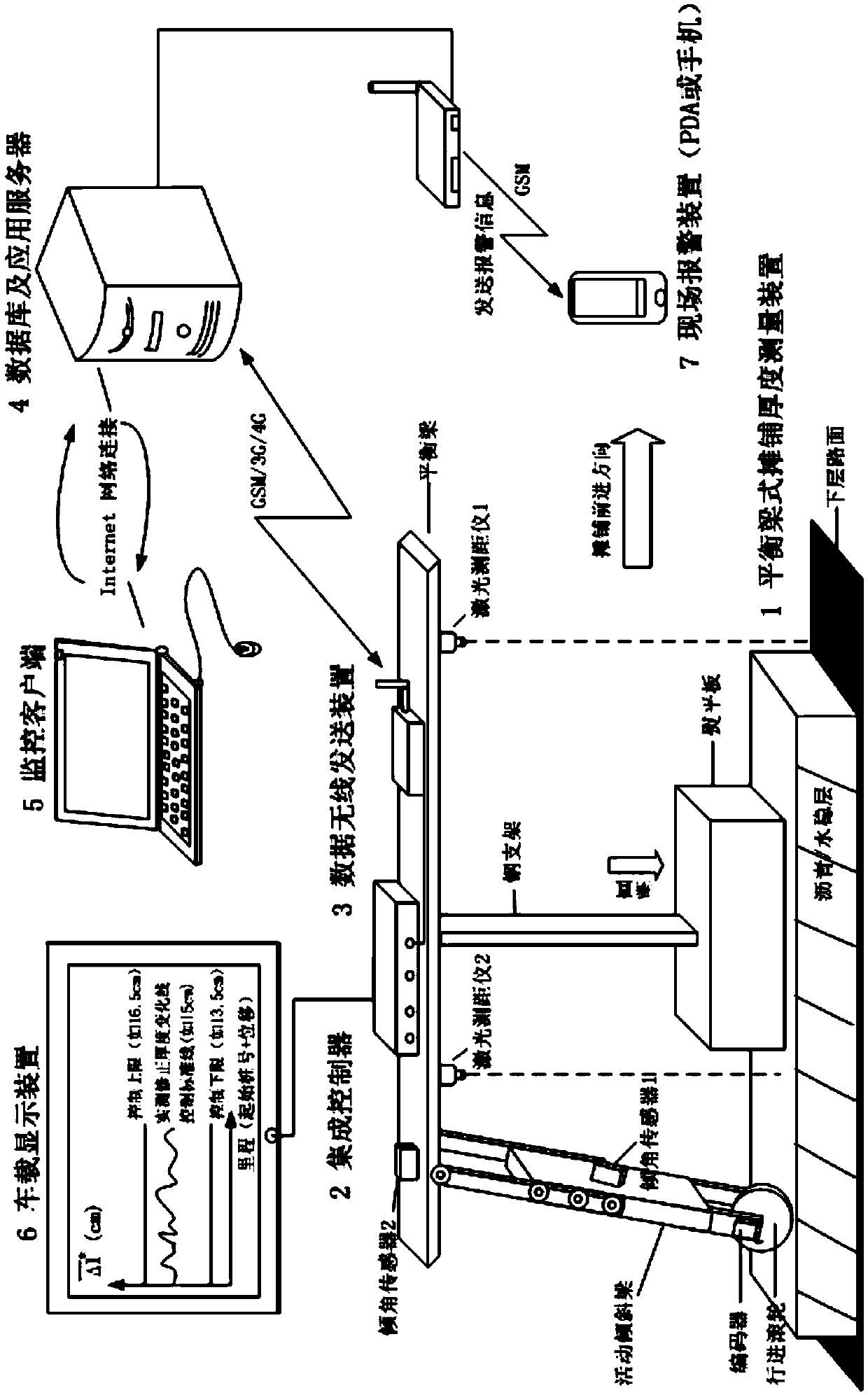

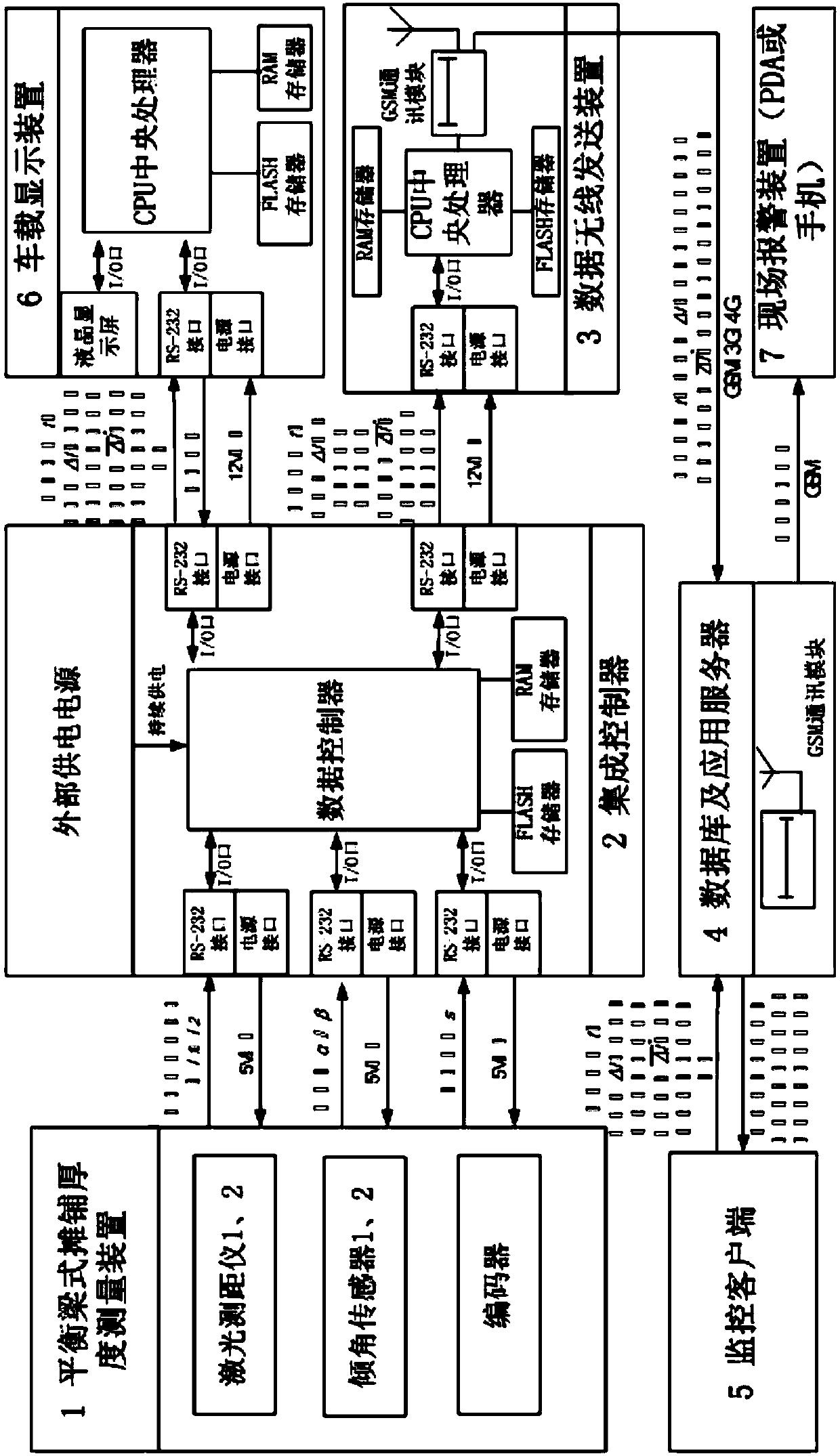

[0055] Aiming at the quality control of highway pavement, to realize automatic, real-time and high-precision monitoring of road pavement thickness, the example of the present invention provides a balance beam type road pavement real-time monitoring device for pavement thickness. The composition and structure diagram of the device of the present invention is shown in figure 1 , Including: balanced beam paving thickness measuring device, integrated controller, data wireless transmission unit (DTU), database and application server, monitoring client, vehicle display device, on-site alarm device, a total of seven parts.

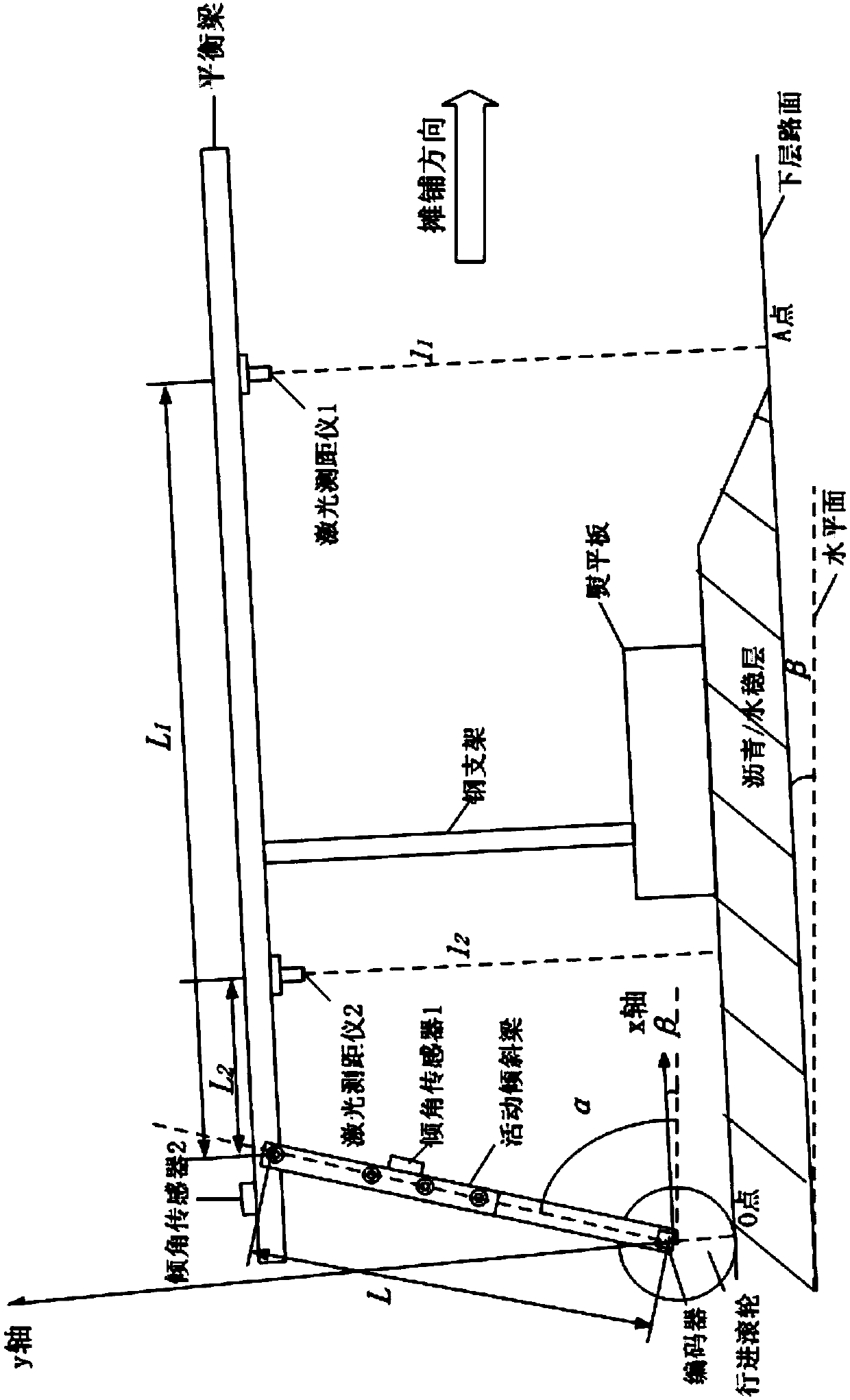

[0056] (1) Balance beam type paving thickness measuring device

[0057] Balance beam type paving thickness measuring device consists of balance beam, movable inclined beam, laser range finder (2, CANKEYPH80A type laser range finder can be used), steel bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com