Electrolytic corrosive agent of industrial pure titanium TA2 and electrolytic polishing corrosion method

An industrial pure titanium and electropolishing technology, applied in the field of metallographic structure detection, can solve the problems of poor operation by new experimental operators and unsatisfactory corrosion effect of industrial pure titanium TA2, and achieve good erosion effect, good corrosion effect, and preparation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

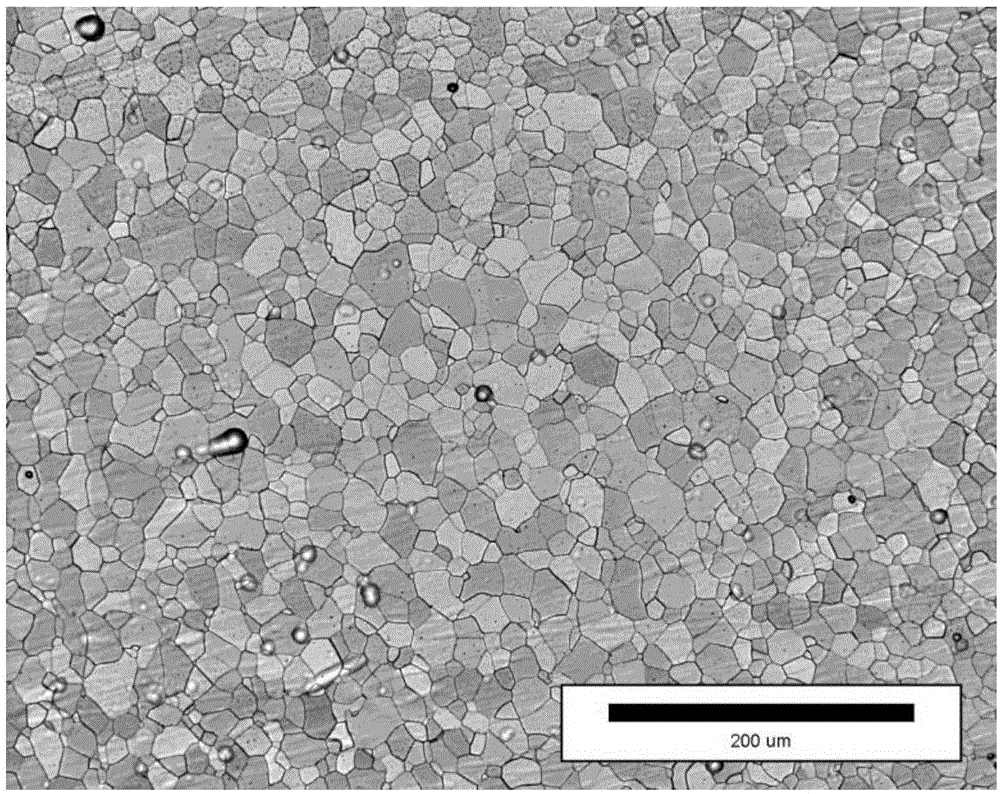

[0035] The industrially pure titanium TA2 in the annealed state is inlaid with dental tray powder, and after curing, it is ground with 120#, 320#, 600# (1000#) sandpaper in sequence according to the preparation method of the metallographic sample. After replacing the sand paper, the grinding direction is perpendicular to the wear marks of the previous sand paper, and the wear marks of the previous process are removed. After grinding each type of sandpaper, the sample should be cleaned to avoid leaving the residual abrasive from the previous process in the next process, so as to protect the surface of the sample.

[0036] After grinding the sample, use No. 1 electrolytic corrosion agent (HF: 90ml, (NH 4 ) 2 S 2 o 8 : 10g, CH 3 CH 2 OH: 200ml, distilled water: 360ml) for electrolytic corrosion, electrolytic corrosion parameters are: polishing voltage: 50V, electrolyte flow rate: 20, electropolishing corrosion time 50s; corrosion voltage: 25V, electrolyte flow rate 20, corro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com