Method for detecting deep ultraviolet laser radiation induction surface change of CaF2 optical substrate

A technology of laser radiation and change detection, applied in fluorescence/phosphorescence, Raman scattering, material excitation analysis, etc., can solve the degradation of microscopic imaging clarity, difficult to accurately locate damage morphology, observation and accurate judgment of surface morphology difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

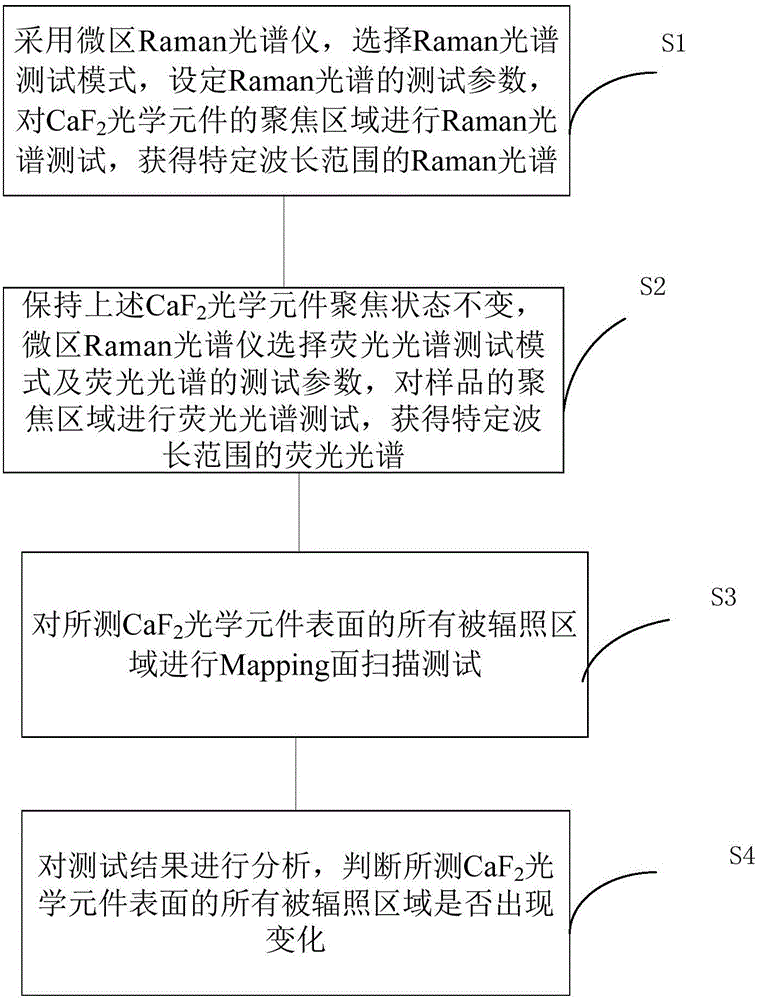

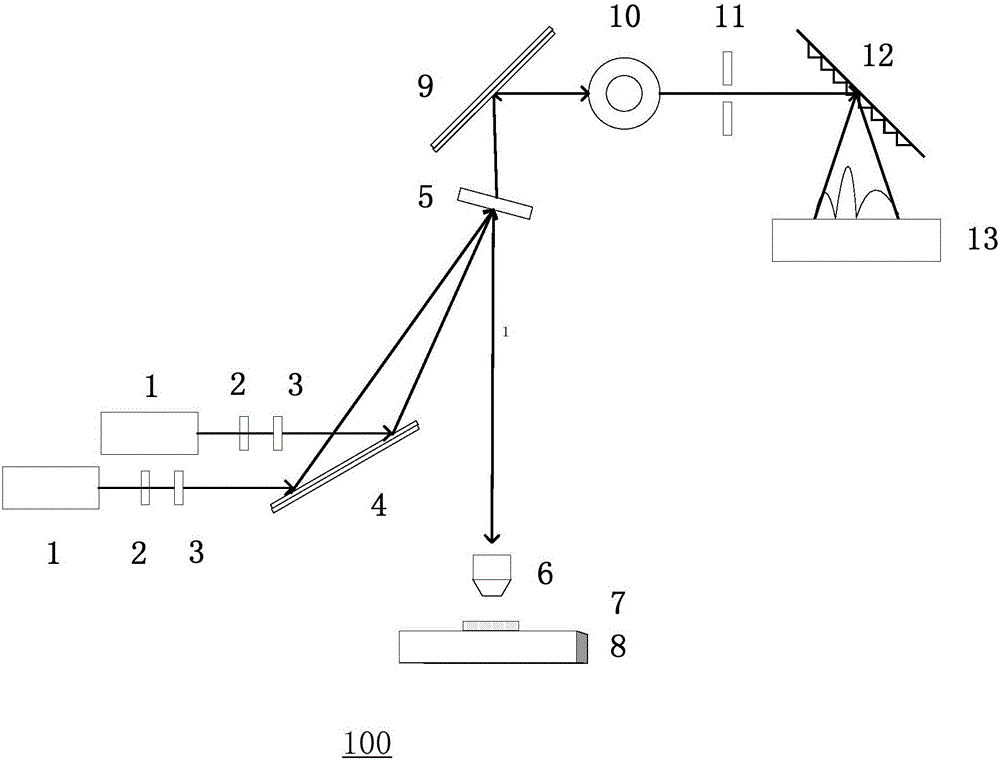

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

[0023] Refer below Figure 1 to Figure 2 To the CaF of the embodiment of the present invention 2 A method for detecting surface changes induced by deep ultraviolet laser radiation on optical substrates is described in detail.

[0024] Raman spectroscopy and fluorescence spectroscopy are two relatively mature techniques for the study of crystal materials and surfaces, and have been widely used in the characterization of various materials. For long-term irradiation of CaF with high repetition rate and low energy density deep ultraviolet laser 2 The irradiated surface of the optical el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com