Method for adjusting near-infrared light based on silver nano-wire (Ag NW) substrate electrochromic material

An electrochromic material and silver nanowire technology, applied in nonlinear optics, optics, instruments, etc., can solve problems such as reduced optical transmittance, poor toughness of glass, and lack of near-infrared intelligent control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

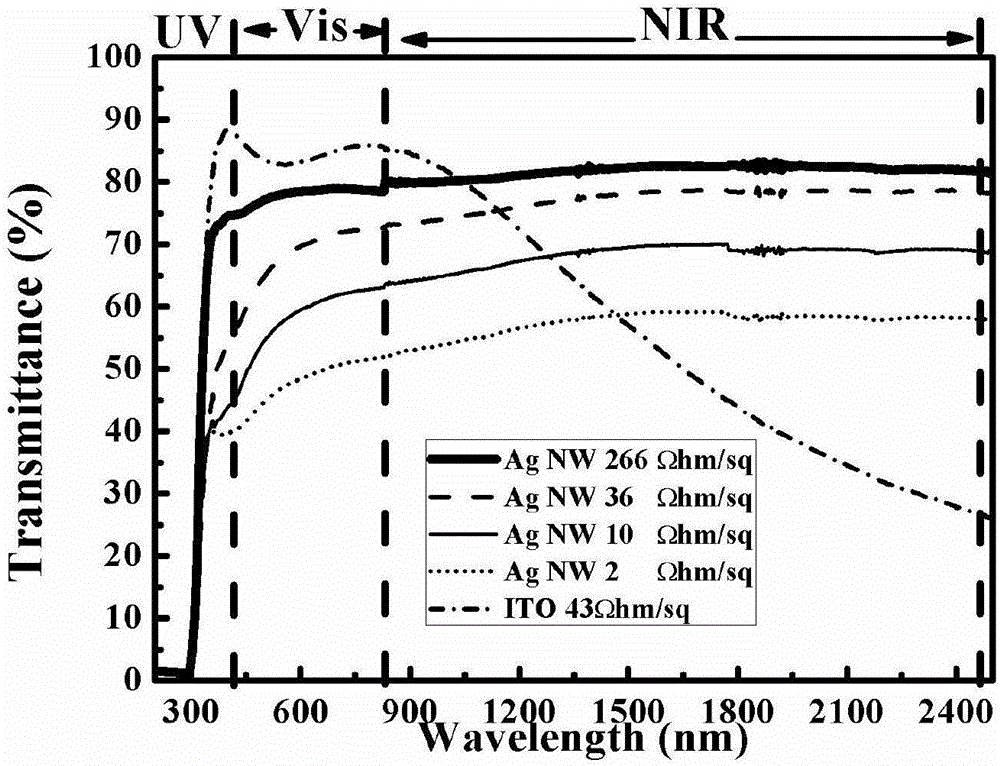

[0024] Silver nanowire (Ag NW) substrate WO 3 Electrochromic material modulates near-infrared light

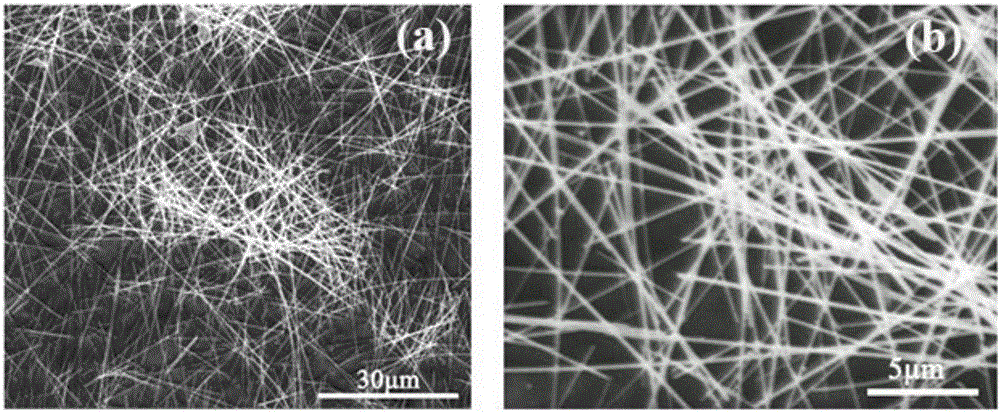

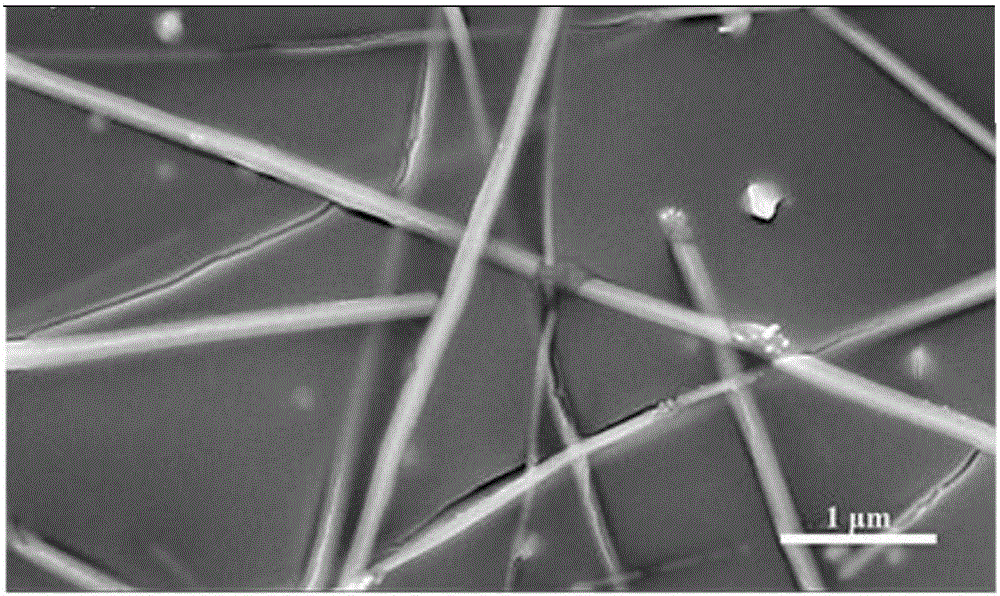

[0025] 1) Silver nanowires (about 100 nm in radius) with an aspect ratio of 700 were prepared by hydrothermal method, and then a 0.01 g / ml PVA solution with high cohesiveness, colorless transparency and good chemical stability was prepared. At the same time, a 3 mg / L silver nanowire ethanol solution was prepared. Using the spin-coating coating process, a layer of PVA bonding layer was spin-coated on the glass substrate at a speed of 2500 rpm for 20 minutes, and then silver nanometers were spin-coated on the PVA layer at a speed of 3500 rpm for 30 seconds. Then, a transparent conductive electrode was prepared by applying a pressure of 100 N to the electrode at 150° C. in a vacuum environment of -0.1 MPa.

[0026] 2). Preparation of WO on silver nanowire conductive glass substrate by electrochemical deposition method 3 electrochromic film, followed by LiClO 4 The electrolyte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com