Steady state junction temperature prediction model of crimping IGBT module considering thermal coupling

A prediction model and thermal coupling technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of complex heat dissipation paths, no heat sinks, low junction temperature estimates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

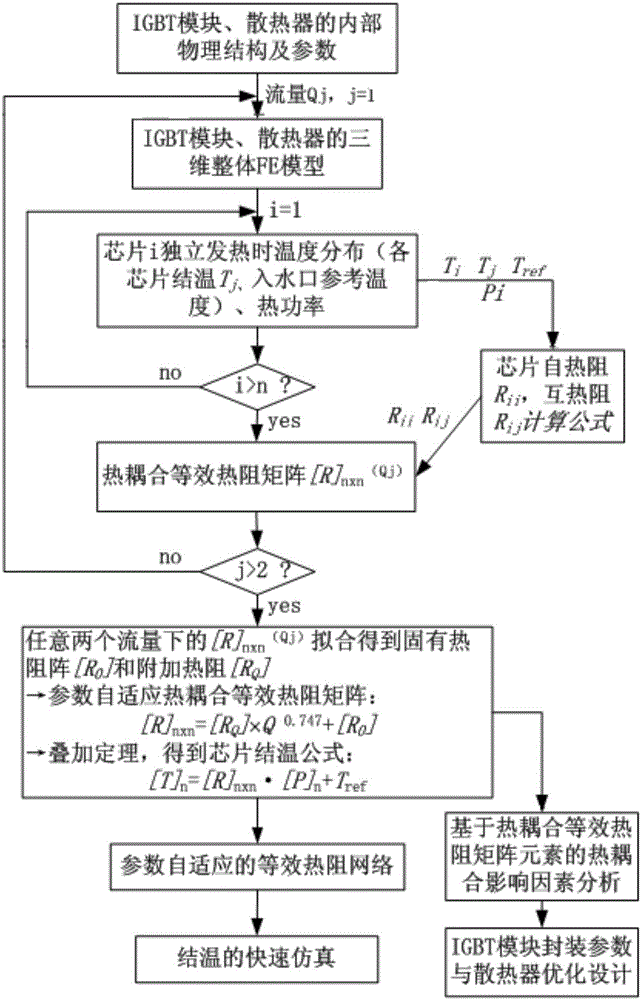

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings. The invention proposes a pressure-connected IGBT module steady-state junction temperature prediction model considering thermal coupling. figure 1 It is a block flow diagram of the method of the present invention, and the specific implementation steps are as follows:

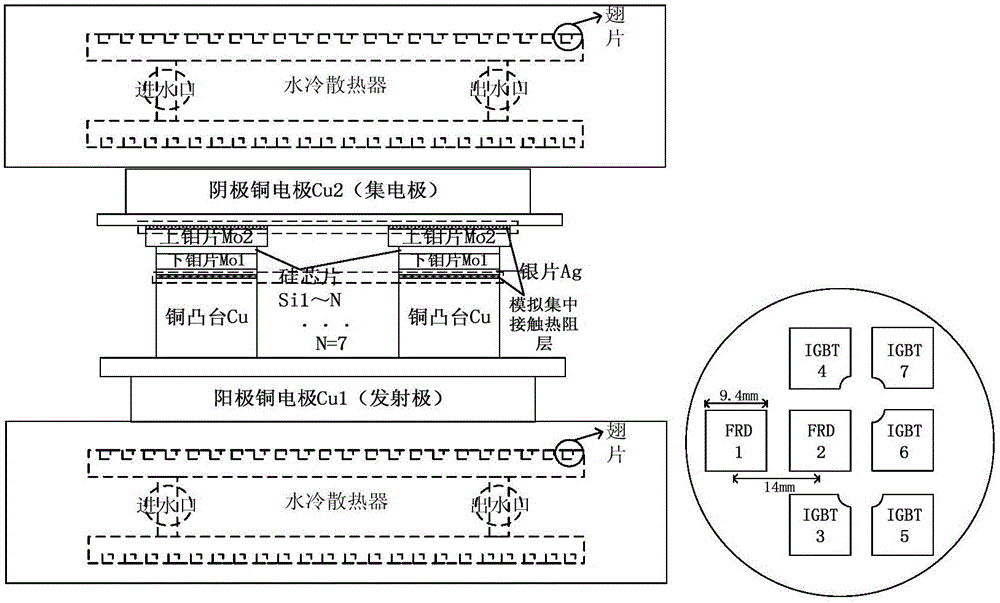

[0036] Step 1: Obtain the physical structure and material parameters of the press-fit IGBT module and its heat sink, as shown in Table 1 and figure 2 shown;

[0037] Table 1 IGBT module T0360NB25A material parameters

[0038]

[0039] Step 2: Based on the finite element simulation software, establish a three-dimensional simulation model of the IGBT module, and further obtain a three-dimensional overall simulation model of the IGBT module and the radiator;

[0040] The model is simplified as follows: 1) The thermal conductivity of the ceramic shell is small and the module is generally filled with iner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com