Installation structure of photovoltaic assembly

A photovoltaic module and installation structure technology, which is applied to the support structure of photovoltaic modules, photovoltaic power generation, photovoltaic modules, etc., can solve the problems of large frame gaps and no drainage channels, etc., achieve waterproof and sealing, reduce manufacturing and installation costs, The effect of improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to fully explain the implementation of the present invention, the following provides implementation examples of the present invention. These implementation examples are merely illustrative of the present invention and do not limit the scope of the present invention.

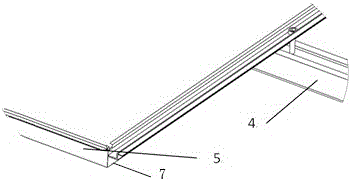

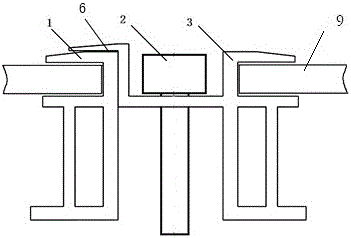

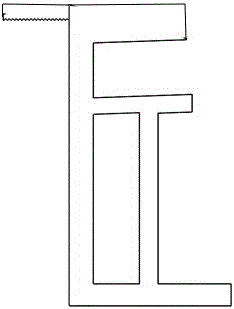

[0011] The present invention will be explained in further detail in conjunction with the accompanying drawings, which are marked as: 1. aluminum alloy frame A; 2. bolts; 3. aluminum alloy frame C; 4. beams; 5. aluminum alloy frame B; 6. waterproof rubber cotton ; 7. Water guide; 8. Reverse B-shaped flat eaves; 9. Photovoltaic panels.

[0012] It can be seen from the figure: a photovoltaic module installation structure, including beam 4, photovoltaic modules, the photovoltaic module includes aluminum alloy frame A1, aluminum alloy frame B5, aluminum alloy frame C3, photovoltaic panel 9, aluminum alloy frame A1 includes a profile body with a rectangular cross section. A photovoltaic cell panel holding gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com