Allogeneic decalcified bone and titanium stent combined material for rhinoplasty filling and preparation method of allogeneic decalcified bone and titanium stent combined material

A demineralized bone, allogeneic technology, used in prostheses, nose implants, medical science, etc., can solve the problems of complex production process, prone to displacement and wear, and achieve the effect of preventing pain and preventing movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

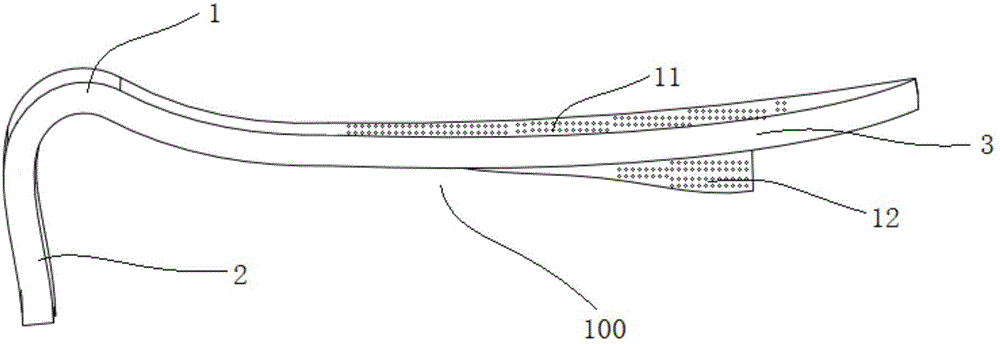

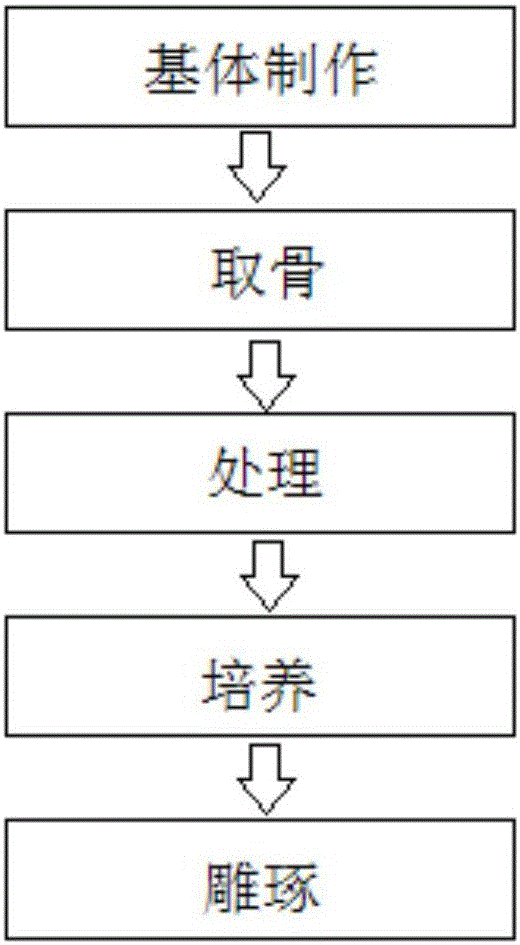

[0043] refer to image 3 As shown, the present invention also proposes a method for preparing a material for rhinoplasty filling allogeneic decalcified bone combined with titanium scaffold, comprising the following steps:

[0044] A) matrix production, the nasal bone matrix is made of titanium alloy material;

[0045] B) taking bone and obtaining allogeneic cartilage in a sterile environment;

[0046] C) treatment, degreasing, decalcifying, deproteinizing and sterilizing the obtained allogeneic cartilage in sequence;

[0047] D) culturing, assembling the treated allograft cartilage in step C onto the nasal bone matrix, and culturing for 24 hours,

[0048] E) Carve, carve the nasal bone matrix into the required shape after the cultivation in step D).

[0049] Concrete processing in the step C of the present invention comprises:

[0050] (1) immersing the allograft cartilage in a mixed liquid of chloroform and methanol for 6-24 hours; wherein: the volume ratio of chlorofor...

Embodiment 1

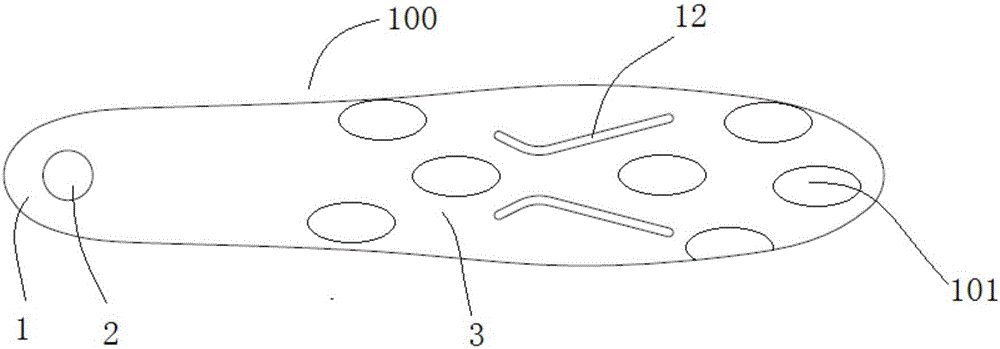

[0056] 1. The nasal bone matrix is made of titanium alloy material, and there are many hollow holes on the nasal bone matrix;

[0057] 2. The allogeneic rib cartilage is obtained under a sterile environment; the eleventh or twelfth rib is preferably obtained, cleaned with distilled water and soaked;

[0058] 3. Immerse the allogeneic cartilage in a mixed liquid of chloroform and methanol for 24 hours to degrease; wherein: the volume ratio of chloroform and methanol in the mixed liquid of chloroform and methanol is 1:1, and wash it with distilled water after taking it out;

[0059] 4. Immerse the degreased allograft cartilage in a hydrochloric acid solution with a concentration of 0.5mol / L, and keep stirring for 12 hours for decalcification, and wash it with distilled water after taking it out;

[0060] 5. Immerse the decalcified allogeneic cartilage in a mixed solution of TritonX-100 and ammonia water for 72 hours to deproteinize; wherein, the volume percentage of TritonX-10...

Embodiment 2

[0065] 1. The nasal bone matrix is made of titanium alloy material, and there are many hollow holes on the nasal bone matrix;

[0066] 2. Obtain allogeneic ear cartilage in a sterile environment; clean and soak in distilled water;

[0067] 3. Immerse the allogeneic cartilage in a mixed liquid of chloroform and methanol for 24 hours to degrease; wherein: the volume ratio of chloroform and methanol in the mixed liquid of chloroform and methanol is 1:1, and wash it with distilled water after taking it out;

[0068] 4. Immerse the degreased allograft cartilage in a hydrochloric acid solution with a concentration of 0.6mol / L, and keep stirring for 12 hours for decalcification, and wash it with distilled water after taking it out;

[0069] 5. Immerse the decalcified allogeneic cartilage in a mixed solution of TritonX-100 and ammonia water for 72 hours to deproteinize; wherein, the volume percentage of TritonX-100 in the mixed solution of TritonX-100 and ammonia water is 1 %, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com