3D printing and electrolytic polishing combined machining system for CoCrMo dental crown

A technology of electrolytic polishing and 3D printing, which is applied in the direction of electrolytic components, electrolytic process, additive processing, etc., can solve the problems of low precision, high surface roughness, complicated polishing process, etc., and achieve high production efficiency, satisfactory surface roughness, Tissue compaction and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

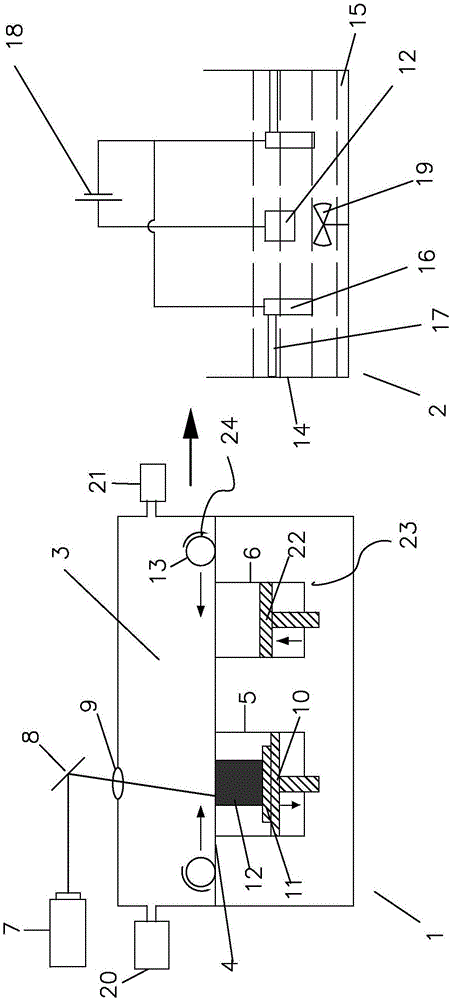

[0028] Such as figure 1 As shown, a CoCrMo alloy dental crown 3D printing and electrolytic polishing composite processing system includes: laser selective melting printing equipment 1 and electrolytic polishing equipment 2 for polishing the product 12 printed by the laser selective melting printing equipment, said The laser selective melting printing equipment 1 includes an optical transmission system and a vacuum chamber 3 for the laser of the optical transmission system to enter. The vacuum chamber 3 is provided with a forming platform 11 that can be lifted. The vacuum chamber 3 is also provided with A powder feeding device 23 for conveying printing powder. The powder feeding device 23 is connected with a powder spreading device 24 capable of paving the printing powder there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com