Preparation method for difluorosulfonylimide salt

A technology of difluorosulfonimide salt and difluorosulfonimide, which is applied in the field of preparation of electrolyte salts for electrochemical devices, can solve problems such as product loss, large environmental protection burden, energy storage density and safety conflicts, and achieve The product yield is improved, the reaction temperature is precisely controlled, and it is beneficial to the removal of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0030] The preparation method of difluorosulfonimide salt, comprises the following steps:

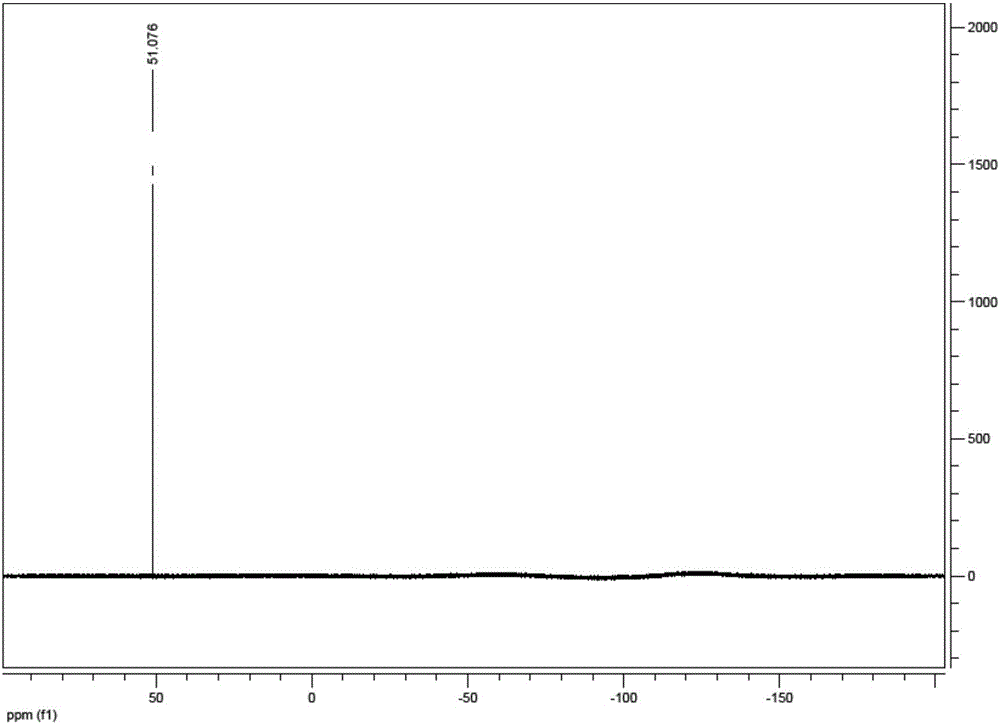

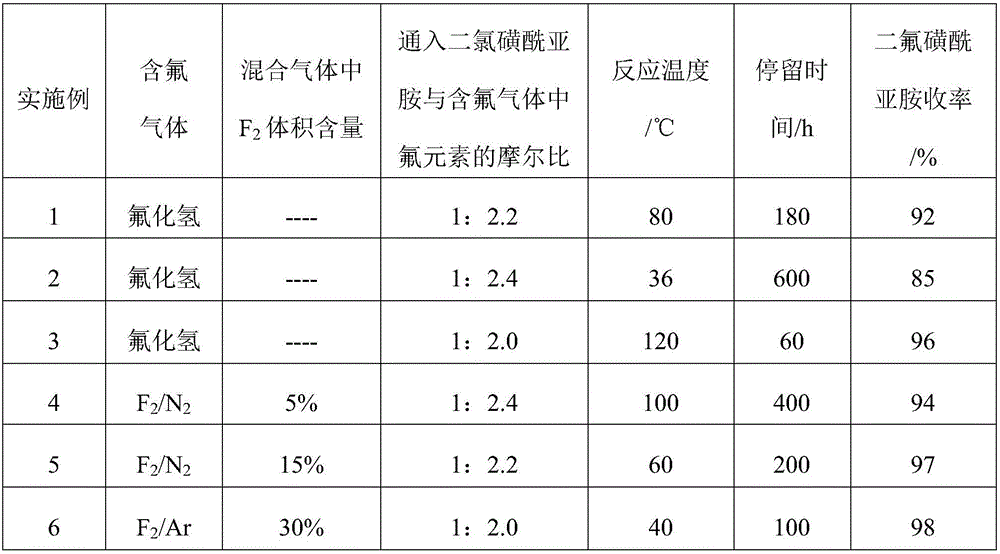

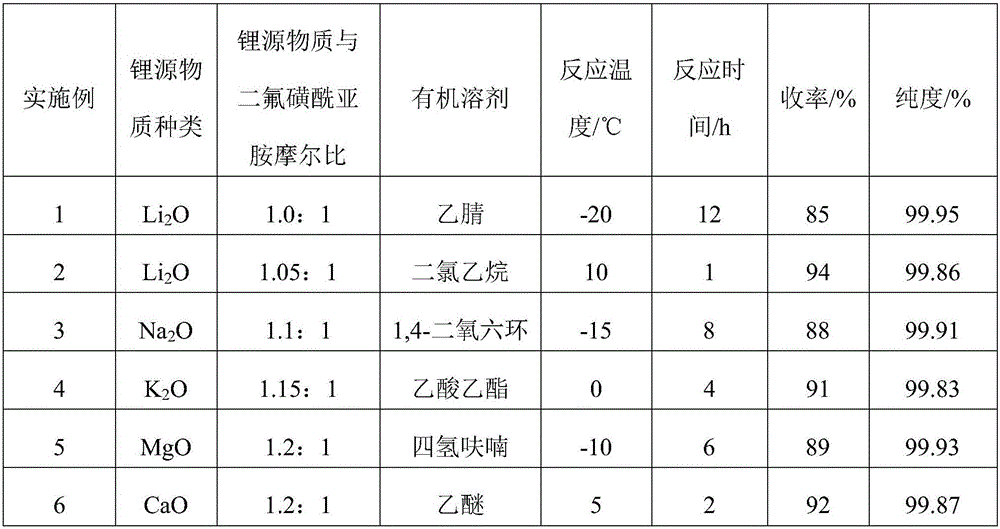

[0031] (1) Preparation of difluorosulfonimide (see Table 1 for specific preparation parameters): use a metering device to feed liquid dichlorosulfonimide and fluorine-containing gas into the microchannel reactor, wherein dichlorosulfonimide The flow rate is 30kg / h. After the two raw materials are reacted in the microchannel reactor, the gas-liquid separation is carried out first, and then the liquid phase is subjected to vacuum distillation, and the fraction at 98-102°C / 15mmHg is collected to obtain difluorosulfonimide Colorless transparent liquid. (2) Preparation of difluorosulfonimide salt (see Table 2 for specific preparation parameters): Dissolve difluorosulfonimide in an organic solvent, then add an oxide of an alkali metal or an oxide of an alkaline earth metal, in- React at 20-10°C for 1-12 hours to obtain the difluorosulfonimide salt. After the reaction is completed, filter at ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com