Harmless oil sludge recycling device and using method thereof

A technology for sludge and sludge, which is applied in dewatering/drying/concentrating sludge treatment, mining wastewater treatment, etc., can solve the problems of deoiling effect and poor dehydration effect, etc. The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

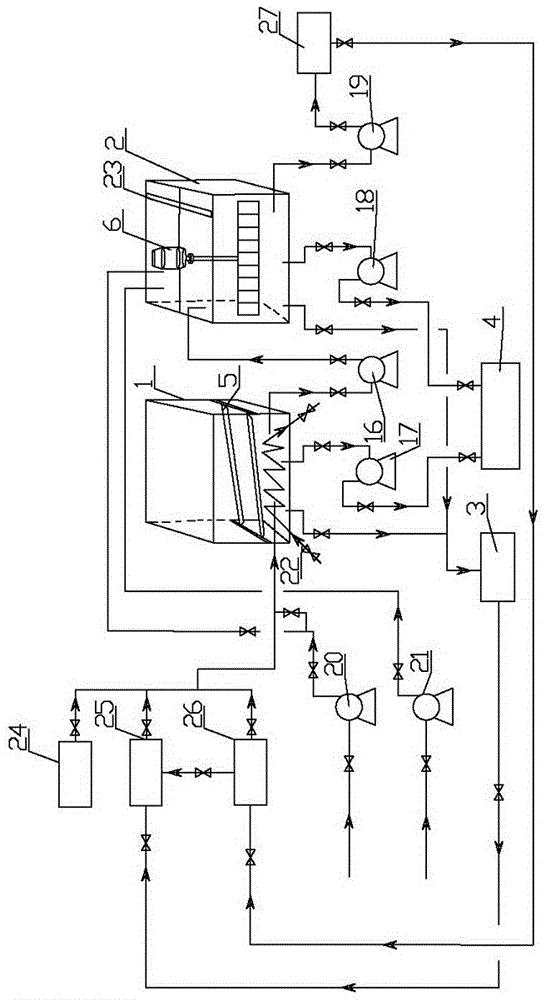

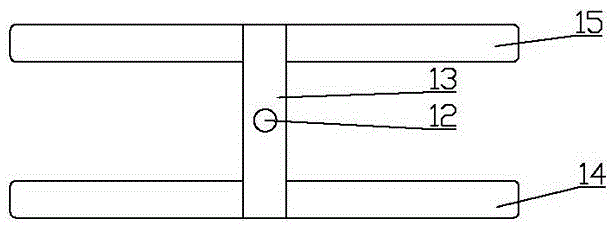

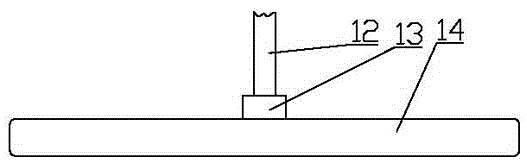

[0027] Embodiment 1: as attached Figures 1 to 5As shown, the waste oil sludge harmless recycling device includes a waste oil dehydration sedimentation tank 1, a waste oil purification tank 2, a sewage purification treatment equipment 3 and a sludge treatment equipment 4, and a waste oil dehydration sedimentation tank 1 is provided with a sewage Sludge inlet, at the lower end of the sludge dehydration sedimentation tank 1, there are respectively a sludge oil outlet, a first dehydration outlet connected to the sewage inlet of the sewage purification treatment equipment 3 through pipelines, and a sludge inlet of the sludge treatment equipment 4 The first sludge outlet connected through the pipeline is respectively provided with a demulsifier dosing port, a flocculant dosing port, and a dirty oil inlet connected with the dirty oil outlet through a pipeline on the upper part of the dirty oil purification tank 2. The lower end of the purification tank 2 is provided with a purified ...

Embodiment 2

[0042] Embodiment 2: as attached figure 1 As shown, the using method of the sludge harmless recycling device described in embodiment 1 is carried out as follows: the oily sewage produced in the production process of the refinery 25 and the oil storage process of the oil storage tank area 26 and The waste oil derived from the oil field 24 is used as sludge; the first step is to send the sludge into the sludge dehydration sedimentation tank 1, and then add a mass percentage of 1.3% to 1.5% demulsifier solution, add 40 kg to 45 kg of demulsifier per ton of sludge, after the sludge is evenly mixed with the added demulsifier under the stirring of the fast mixer 5, the sludge is demulsified and separated for the first time, The stirring time is 1 hour to 2 hours. After the stirring is completed, the mixed dirty oil separated in the upper part of the sewage oil dehydration sedimentation tank 1 is transported to the sewage oil purification tank 2, and the demulsification separation in...

Embodiment 3

[0050] Example 3: As an optimization of Example 2, in the first step, the 1.3% to 1.5% demulsifier solution is formed by dissolving the demulsifier in desalted water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com