Preparation method for candesartan cilexetil crystals

A technology of candesartan cilexetil and crystallizer, applied in the field of crystallization, can solve the problems of poor fluidity, inability to effectively meet the different needs of customers, electrostatic adsorption, etc., and achieve the effect of uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

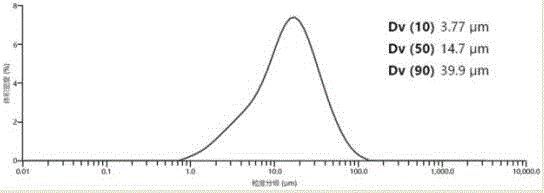

[0025] Add 1 g of candesartan cilexetil into a three-neck flask containing 100 g of methanol and water mixed solvent (mass ratio: 23:2), stir and dissolve at 30°C, and after continuous stirring for 60 minutes, filter and decolorize; transfer the filtrate into In the crystallizer, add 8 g of water to the crystallizer at 30 ° C, and the flow rate is 0.8 g / min; after adding water, add 0.01 g of seed crystals to the clear solution, and grow crystals at this temperature for 1 hour; Subsequently, 80 g of water was added to the crystallizer at a rate of 0.8 g / min, and then the crystal was grown for another 2 hours. Suction filter, wash the filter cake with water, and dry at 40° C. under normal pressure for 12 hours. The final product yield is 86.4%, and the HPLC purity is 99.91%, and the main particle size of the product is 14.70 microns (such as figure 1 Shown), there is no electrostatic adsorption between product particles.

Embodiment 2

[0027] Add 3 g of candesartan cilexetil into a three-neck flask filled with 100 g of methanol and water mixed solvent (mass ratio: 23:2), stir and dissolve at 45°C, and after continuous stirring for 40 minutes, filter and decolorize; transfer the filtrate into In the crystallizer, add 8 g of water to the crystallizer at 45 ° C, and the flow rate is 0.5 g / min; after adding water, add 0.02 g of seed crystals to the clear solution, and grow crystals at this temperature for 1 hour; Subsequently, 80 g of water was added to the crystallizer at a rate of 0.5 g / min, and then the crystal was grown for another 2 hours. Suction filter, wash the filter cake with methanol, and dry at 45° C. under normal pressure for 7 hours. The yield of the final product is 85.2%, the HPLC purity is 99.92%, the main particle size of the product is 13.82 microns, and there is no electrostatic adsorption phenomenon between the product particles.

Embodiment 3

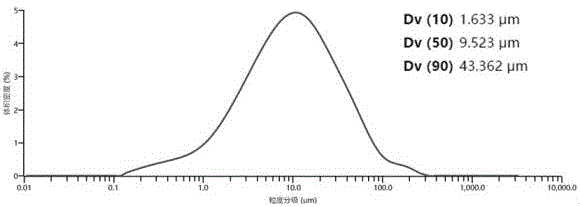

[0029] Add 5 g of candesartan cilexetil into a three-neck flask filled with 100 g of ethanol and water mixed solvent (mass ratio: 9:1), stir and dissolve at 30°C, and after continuous stirring for 40 minutes, filter and decolorize; transfer the filtrate into In the crystallizer, add 15 g of water to the crystallizer at 30 ° C, and the flow rate is 1 g / min; after adding water, add 0.03 g of seed crystals to the clear solution, and grow crystals at this temperature for 1.5 hours; Subsequently, 200 g of water was added to the crystallizer at a rate of 2 g / min, and then the crystal was grown for another 3 hours. Suction filter, wash the filter cake with water, and dry at 40° C. under normal pressure for 12 hours. The final product yield is 87.1%, and the HPLC purity is 99.92%, and the main particle size of the product is 9.523 microns (such as figure 2 Shown), there is no electrostatic adsorption between product particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com