Lanthanide-series material containing nanometer polyester imide film and preparation method thereof

A technology of lanthanides and polyesterimides, applied in the direction of fireproof coatings, coatings, etc., to achieve good surface quality and mechanical properties, improve dispersion, enhance mechanical properties and insulation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

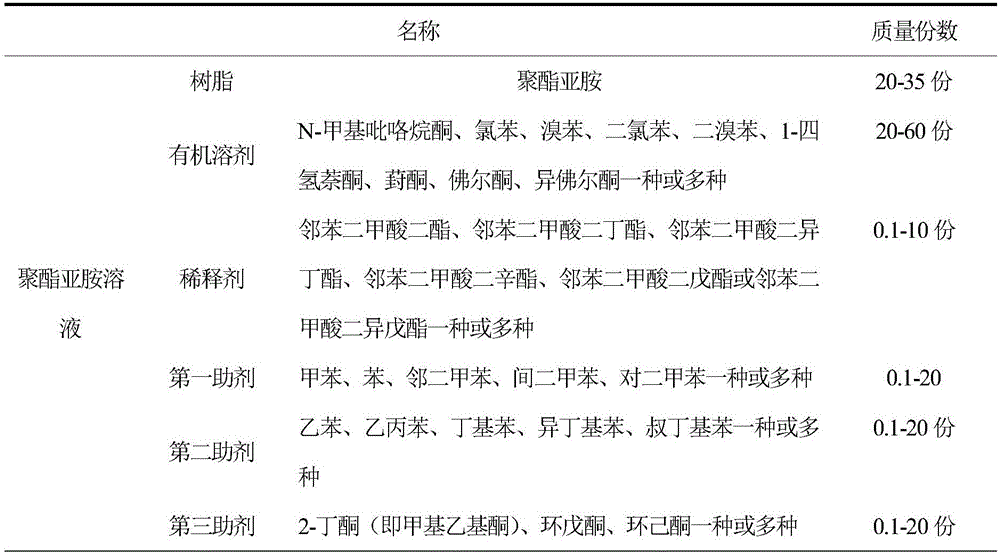

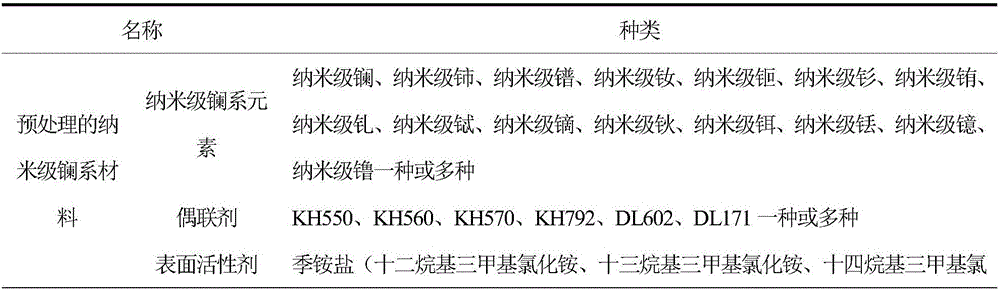

[0058] The formulation of the nano-polyesterimide film containing lanthanide material provided in this example is shown in Table 3.

[0059] table 3

[0060]

[0061]

[0062] The preparation method of the nano-polyesterimide film containing the lanthanide material provided by the present embodiment, according to the formula in the above table 3, it includes the steps in the following order:

[0063] 1) Preparation of polyesterimide solution: dissolve polyesterimide resin in an organic solvent, stir to dissolve completely, then add diluent, first auxiliary agent, second auxiliary agent and third auxiliary agent in sequence, after completely dissolving Obtain polyester imine solution for subsequent use;

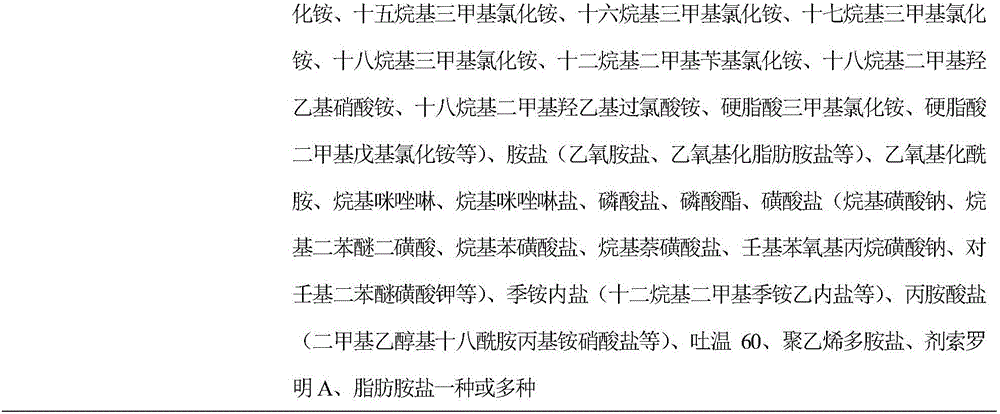

[0064] 2) Pretreatment of nanoscale lanthanide material: Mix nanoscale nanoscale lanthanide material, silane coupling agent and surfactant evenly, then disperse in an ultrasonic cleaner for 10 minutes at room temperature, and set aside;

[0065] 3) Preparation of polye...

Embodiment 2

[0069] The formula of the nano-polyesterimide film containing lanthanide material provided in this embodiment is shown in Table 4.

[0070] Table 4

[0071]

[0072]

[0073] The preparation method of the nano-polyesterimide film containing the lanthanide material provided by the present embodiment, according to the formula in the above table 4, it includes the steps in the following order:

[0074] 1) Preparation of polyesterimide solution: dissolve polyesterimide resin in an organic solvent, stir to dissolve completely, then add diluent, first auxiliary agent, second auxiliary agent and third auxiliary agent in sequence, after completely dissolving Obtain polyester imine solution for subsequent use;

[0075] 2) Pretreatment of nano-scale lanthanide material: Mix nano-scale nano-scale lanthanide material, silane coupling agent and surfactant evenly, then disperse in an ultrasonic cleaner for 20 minutes at room temperature, and set aside;

[0076] 3) Preparation of pol...

Embodiment 3

[0079] The formula of the nano-polyesterimide film containing lanthanide material provided in this embodiment is shown in Table 5.

[0080] table 5

[0081]

[0082] The preparation method of the nano-polyesterimide film containing the lanthanide material provided by the present embodiment, according to the formula in the above table 5, it includes the steps in the following order:

[0083] 1) Preparation of polyesterimide solution: dissolve polyesterimide resin in an organic solvent, stir to dissolve completely, then add diluent, first auxiliary agent, second auxiliary agent and third auxiliary agent in sequence, after completely dissolving Obtain polyester imine solution for subsequent use;

[0084] 2) Pretreatment of nanoscale lanthanide material: mix nanoscale nanoscale lanthanide material, silane coupling agent and surfactant evenly, then disperse in an ultrasonic cleaner for 30 minutes at room temperature, and set aside;

[0085] 3) Preparation of polyesterimine sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com