Flame-retardant silicone rubber material

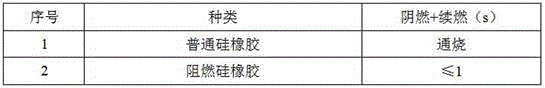

A technology of silicone rubber and decabromodiphenyl ether, which is applied in the field of gas mask cover materials, can solve problems such as poor flame retardant performance, and achieve the effects of improving flame retardant performance, wide application range and increasing flame retardant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A flame-retardant silicone rubber material, comprising the following components by weight:

[0024] Silicone rubber 100 parts, antimony trioxide 20 parts, decabromodiphenyl ether 30 parts, DCP 2 parts, zinc stearate 10 parts.

[0025] The preparation method is as follows:

[0026] XK-160mm open type rubber mixing machine is used for compounding rubber, and the speed ratio of the rollers is 1:1.25; when the silicone rubber is mixed, the temperature of the front roller is 60°C, and the temperature of the rear roller is slightly higher, which is 75°C; the mixing process is as follows :

[0027] (1) Adjust the roller distance to 0.8, add silicone rubber to make it cover the front roller;

[0028] (2) Add zinc stearate and DCP and knead for 15 minutes;

[0029] (3) Adjust the roller distance to 1.2, add antimony trioxide and decabromodiphenyl ether, and mix for 30 minutes;

[0030] (4) Adjust the roller distance to 0.8, and pass six times before and after thinning;

[0...

Embodiment 2

[0033] A flame-retardant silicone rubber material, comprising the following components by weight:

[0034] Silicone rubber 100 parts, antimony trioxide 10 parts, decabromodiphenyl ether 50 parts, DCP 6 parts, zinc stearate 5 parts.

[0035] The preparation method is as follows:

[0036] XK-160mm open type rubber mixing machine is used for mixing the rubber material, and the speed ratio of the rollers is 1:1.25; when the silicone rubber is mixed, the temperature of the front roll is 65°C, and the temperature of the rear roll is slightly higher, which is 72°C; the mixing process is as follows :

[0037] (1) Adjust the roller distance to 0.8, add silicone rubber to make it cover the front roller;

[0038] (2) Add zinc stearate and DCP and knead for 20 minutes;

[0039] (3) Adjust the roller distance to 1.2, add antimony trioxide and decabromodiphenyl ether, and mix for 30 minutes;

[0040] (4) Adjust the roller distance to 0.8, and pass six times before and after thinning;

...

Embodiment 3

[0043] A flame-retardant silicone rubber material, comprising the following components by weight:

[0044] Silicone rubber 100 parts, antimony trioxide 30 parts, decabromodiphenyl ether 20 parts, DCP 10 parts, zinc stearate 15 parts.

[0045] The preparation method is as follows:

[0046] XK-160mm open type rubber mixing machine is used for mixing rubber materials, and the speed ratio of the rollers is 1:1.25; when mixing silicone rubber, the temperature of the front roller is 60°C, and the temperature of the rear roller is slightly higher, which is 70°C; the mixing process is as follows :

[0047] (1) Adjust the roller distance to 0.8, add silicone rubber to make it cover the front roller;

[0048] (2) Add zinc stearate and DCP and knead for 15 minutes;

[0049] (3) Adjust the roller distance to 1.2, add antimony trioxide and decabromodiphenyl ether, and mix for 20 minutes;

[0050] (4) Adjust the roller distance to 0.8, and pass six times before and after thinning;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com