Crosslinking agent for sea water-based fracturing fluid as well as preparation method and application of crosslinking agent

A technology of cross-linking agent and base pressure, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of affecting the sand-carrying ability of fracturing fluid, affecting the cross-linking performance of cross-linking agent, and the low cross-linking strength of jelly To achieve the effects of improving offshore fracturing efficiency, easy flowback, and superior viscoelasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

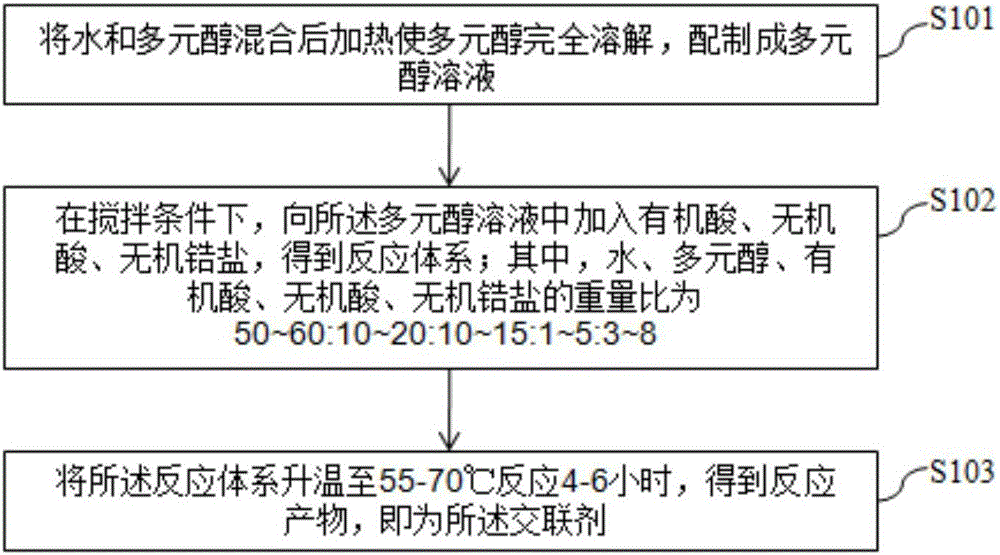

[0035] On the other hand, based on the same inventive concept, the embodiment of the present invention provides a preparation method of the above-mentioned crosslinking agent, see figure 1 ,include:

[0036] Step S101: Mix water and polyol and heat to completely dissolve the polyol to prepare a polyol solution; wherein the dissolving temperature of the polyol is 40° C., and heat for 10-15 min to rapidly and fully dissolve the polyol.

[0037] Wherein, the polyhydric alcohol is one or a mixture of triethanolamine, pentaerythritol and glycerol.

[0038] Step S102: Add organic acid, inorganic acid, and inorganic zirconium salt to the polyol solution under stirring conditions to obtain a reaction system; wherein, the weight ratio of water, polyol, organic acid, inorganic acid, and inorganic zirconium salt is 50~60:10~20:10~15:1~5:3~8;

[0039] Wherein, the organic acid is one of citric acid, lactic acid and acetic acid; the inorganic acid is hydrochloric acid; the inorganic zirc...

Embodiment 1

[0047] Weigh 50 parts of water and 15 parts of pentaerythritol according to the weight ratio and add them into the reactor with a stirring and reflux device, while heating the temperature in the reactor to 40°C and preheating for 10 minutes to completely dissolve the pentaerythritol. Then, under stirring conditions, 12 parts of lactic acid, 3 parts of hydrochloric acid, and 5 parts of zirconium oxychloride octahydrate were successively added into the reactor. While continuing to stir, the temperature in the reactor was raised to 65° C., and reacted at this temperature for 4.5 hours to obtain a light yellow homogeneous liquid, which was the crosslinking agent.

Embodiment 2

[0049] Weigh 55 parts of water and 18 parts of pentaerythritol according to the weight ratio and add them to the reactor with a stirring and reflux device, while heating the temperature in the reactor to 40°C and preheating for 15 minutes to completely dissolve the pentaerythritol. Then, under stirring conditions, 15 parts of acetic acid, 3 parts of hydrochloric acid and 6 parts of zirconium oxychloride octahydrate were successively added into the reactor. While continuing to stir, the temperature in the reactor was raised to 60° C., and reacted at this temperature for 5.5 hours to obtain a light yellow liquid, which was the crosslinking agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com