Method for preparing sulfur-free davidii foex wine

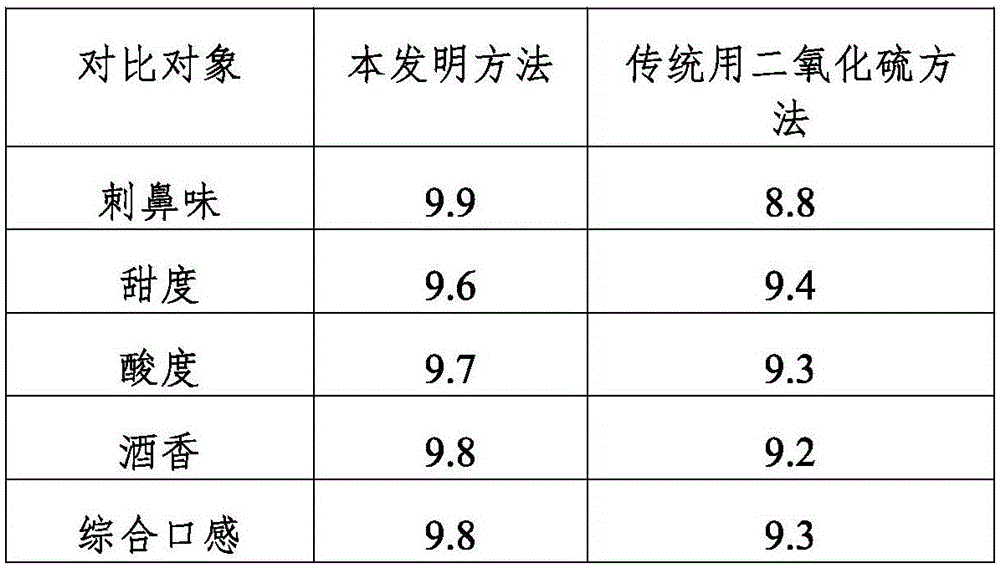

A wine and thorn grape technology, applied in the field of preparation of sulfur-free wine, can solve problems such as human harm, achieve the effects of short production cycle, pure and mellow taste, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of sulfur-free wine, comprising the following steps:

[0029] (1) Boil clear water, cool it to 10°C, set aside, remove impurities from the picked fresh thorn grapes, spray with treated clear water, and then evaporate the moisture on the surface with hot air, wherein the temperature of the hot air is 75°C, The drying time is 55s.

[0030] (2) Put the grapes that have passed step (1) into a crusher, crush them to obtain grape pulp, add pectinase, stir and extract at 30°C for 2 hours, heat the grape pulp to 50°C, and add cellulase , leaching for 80 minutes, and standing for 15 hours, wherein, the amount of pectinase added is 35 mg / L, and the amount of cellulase added is 15 mg / L.

[0031] (3) Send the grape syrup processed through step (2) into a fermenter, add sugar to adjust the sugar content of the grape syrup, the ratio of sugar added in the grape syrup is 0.1: 1, and the temperature of the glucose syrup is adjusted to 25°C. Wrap the feed inlet wi...

Embodiment 2

[0042] A preparation method of sulfur-free wine, comprising the following steps:

[0043] (1) Boil clean water, cool it to 15°C, set aside, remove impurities from the picked fresh thorn grapes, spray with treated clean water, and then evaporate the moisture on the surface with hot air, wherein the temperature of the hot air is 85°C, The drying time is 65s.

[0044] (2) Put the grapes that have passed step (1) into a crusher, crush them to obtain grape pulp, add pectinase, stir and extract at 35°C for 3 hours, heat the grape pulp to 60°C, and add cellulase , leaching for 120min, and standing for 18h, wherein, the amount of pectinase added is 40mg / L, and the amount of cellulase added is 20mg / L.

[0045] (3) Send the grape syrup processed through step (2) into the fermenter, add sugar to adjust the sugar content of the grape syrup, the ratio of sugar added in the grape syrup is 0.2: 1, and the temperature of the glucose syrup is adjusted to be 28°C. Wrap the feed inlet with ste...

Embodiment 3

[0056] A preparation method of sulfur-free wine, comprising the following steps:

[0057] (1) Boil clear water, cool it to 13°C, set aside, remove impurities from the picked fresh thorn grapes, spray with treated clear water, and evaporate the moisture on the surface with hot air, wherein the temperature of the hot air is 80°C, Blow dry time 60s.

[0058] (2) Put the grapes that have gone through step (1) into a crusher, crush them to obtain grape pulp, add pectinase, stir and extract at 33°C for 2.5h, heat the grape pulp to 55°C, add cellulose Enzyme, leaching for 100min, standing still for 17h, wherein, the addition amount of pectinase is 38mg / L, and the addition amount of cellulase is 18mg / L.

[0059] (3) Send the grape syrup processed through step (2) into a fermenter, add sugar to adjust the sugar content of the grape syrup, the ratio of sugar added in the grape syrup is 0.15: 1, and the temperature of the glucose syrup is adjusted to be 26°C. Wrap the feed inlet with s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com