A kind of processing method of high-quality distilled liquor

A processing method and technology for distilled wine, applied in the field of food processing, can solve the problems of high fusel alcohol, low utilization rate of mulberry fruit, and not strong wine aroma in distilled wine, and achieve the effects of unique aroma, unique aroma, and guaranteeing a mellow and positive wine aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

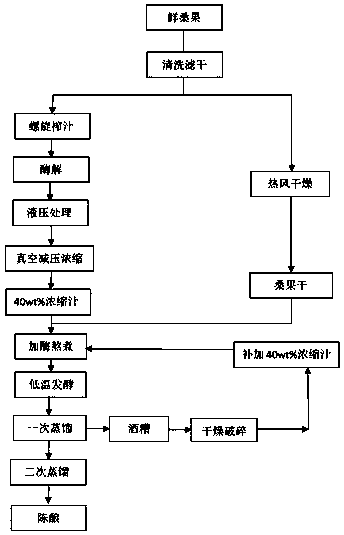

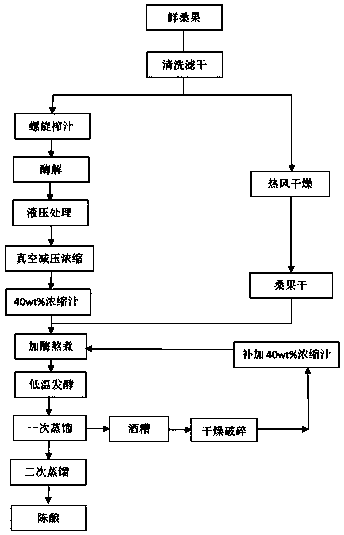

Image

Examples

Embodiment 1

[0035] A processing method for high-quality distilled liquor, comprising the following steps:

[0036] a) Pretreatment of fresh mulberries: picking and selecting 1000kg of mulberry fruits with good maturity as raw materials, pouring them into the water tank, cleaning them, draining them, and using them for later use;

[0037] b) Squeeze the pretreated fresh mulberry fruit with a screw juicer to obtain mulberry puree, and use 45°C warm water to activate pectinase for enzymatic hydrolysis of the pectinase After 45 minutes, pressurize at a pressure of 0.75MPa and a power of 17.5kw for 30 minutes to carry out hydraulic treatment, filter to obtain the original mulberry juice, and carry out vacuum decompression concentration at a vacuum of 0.08MPa and a temperature of 70°C for 5 hours to obtain 40wt% mulberry juice concentrate;

[0038] c) Dry the pretreated fresh mulberries at a temperature of 50°C for 24 hours with hot air to obtain dried mulberries accounting for 32wt% of fresh ...

Embodiment 2

[0046] A processing method for high-quality distilled liquor, comprising the following steps:

[0047] a) Pretreatment of fresh mulberries: picking and selecting 1000kg of mulberry fruits with good maturity as raw materials, pouring them into the water tank, cleaning them, draining them, and using them for later use;

[0048] b) Squeeze the pretreated fresh mulberries with a screw juicer to obtain mulberry puree, and use pectinase activated by warm water at 45°C to enzymolyze the mulberry puree with a dosage of 2mL / L for 40min Afterwards, carry out hydraulic treatment at a pressure of 0.5 MPa and a power of 15 kw for 35 minutes, filter to obtain the original mulberry juice, and carry out vacuum decompression and concentration for 6 hours at a vacuum of 0.07 MPa and a temperature of 60 ° C to obtain 35wt% mulberry concentrated juice;

[0049] c) Dry the pretreated fresh mulberries at a temperature of 45°C for 25 hours with hot air to obtain dried mulberries accounting for 30wt...

Embodiment 3

[0057] A processing method for high-quality distilled liquor, comprising the following steps:

[0058] a) Pretreatment of fresh mulberries: picking and selecting 1000kg of mulberry fruits with good maturity as raw materials, pouring them into the water tank, cleaning them, draining them, and using them for later use;

[0059] b) Squeeze the pretreated fresh mulberries with a screw juicer to obtain mulberry puree, and use 45°C warm water to activate pectinase for 50 minutes. Afterwards, carry out hydraulic treatment at a pressure of 1MPa and a power of 15kw for 35 minutes, filter to obtain the original mulberry juice, and carry out vacuum decompression and concentration for 4 hours at a vacuum degree of 0.09MPa and a temperature of 80°C to obtain 45wt% mulberry fruit concentrate juice;

[0060] c) Dry the pretreated fresh mulberries at a temperature of 45~60°C for 23 hours with hot air to obtain dried mulberries accounting for 35wt% of fresh weight, and then combine them with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com