Overturning plate type continuous fermentation system

A fermentation system, flap-type technology, applied in the field of continuous fermentation system, can solve the problems of poor overall material flow effect, poor mass and heat transfer effect, and difficult discharge, so as to achieve good mass and heat transfer effect and increase the speed of dry fermentation , the effect of increasing gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

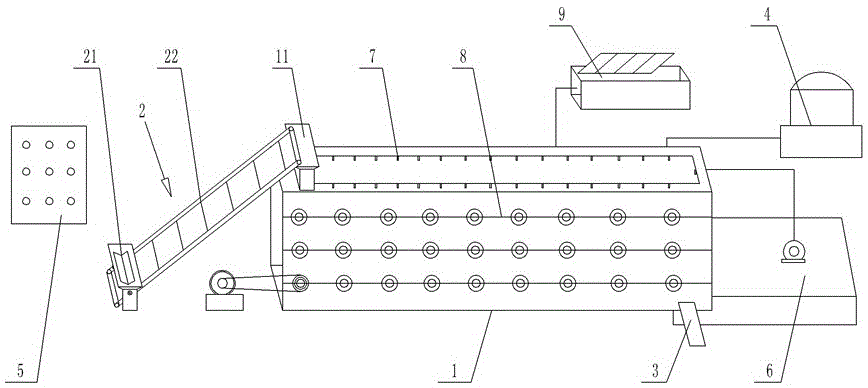

[0023] The flap type continuous fermentation system of the present embodiment, such as figure 1 As shown, it includes a fermentation bin 1 , a feeding device 2 , a discharging device 3 , a gas storage device 4 and a control device 5 .

[0024] The top, upper, lower and bottom of the fermentation bin 1 are respectively provided with a feed port connected to the feed device 2, an exhaust port connected to the gas storage device 4, a discharge port connected to the discharge device 3, and a liquid collection pool6. The gas storage device 4 includes an air intake pipeline, a desulfurization and dehydration mechanism, a pump and an air storage tank.

[0025] A biogas slurry spraying device 7 communicated with the sump 6 is evenly distributed on the top of the fermentation bin 1 . The biogas slurry spraying device 7 communicates with the liquid collection tank 6 through a pipeline, and a delivery pump is arranged on the pipeline.

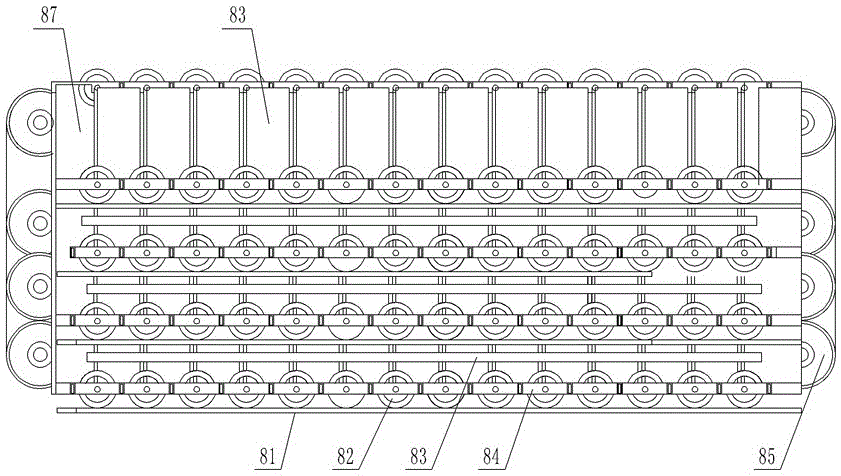

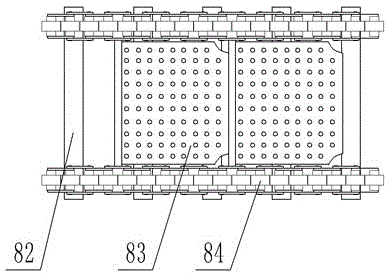

[0026] Such as figure 2 , image 3 and Figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com