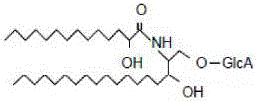

Method for preparing D-glucosylceramide by using soy sauce filter residue

A ceramide and glucosyl-based technology, which is applied in the field of preparing D-glucosyl ceramide, can solve the problems of low content and no economic value, and achieve the effects of improving economic benefits, improving resource utilization and developing high-value by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of method utilizing soy sauce filter residue to prepare D-glucosylceramide, adopts following steps:

[0025] A. Use an inoculation loop to measure 10 rings of Sphingomonas sp. strain, preservation number CICC10694, and 10 rings of Yarrowia lipolytica strain, preservation number CICC 1441; Inoculate into 100 mL activation medium respectively, and described activation medium is made up of the peptone of 0.50% mass ratio, 0.60% NaCl, 5% sucrose, the remainder distilled water; And culture 24 h in constant temperature incubator, culture temperature is At 28 ℃, the pH was controlled to 7.0, and the activated culture solution P of Sphingomonas sp. and the activated culture solution Q of Yarrowia lipolytica strain were obtained respectively, in which (Sphingomonas sp.) The concentration of the bacterial solution in the activated culture solution P of the strain is 1×105CFU / mL, and the concentration of the bacterial solution in the activated culture solution Q of the Yarr...

Embodiment 2

[0030] A kind of method utilizing soy sauce filter residue to prepare D-glucosylceramide, adopts following steps:

[0031] A. Use an inoculation loop to measure 15 strains of Sphingomonas sp., preservation number CICC10694, and 15 strains of Yarrowia lipolytica (Yarrowia lipolytica), preservation number CICC 1441; Inoculate into 100 mL activation medium respectively, the activation medium is composed of peptone of 0.50% by mass ratio, 0.60% of NaCl, 5% of sucrose, the rest of distilled water; At 28°C, the pH was controlled to 7.2, and the activated culture solution P of Sphingomonas sp. and the activated culture solution Q of Yarrowia lipolytica strain were respectively obtained, wherein (Sphingomonas sp.) The concentration of the bacterial solution in the activated culture medium P of the strain is 3×105CFU / mL, and the concentration of the bacterial solution in the activated culture medium Q of the Yarrowia lipolytica strain is 3×105CFU / mL;

[0032] B. Mix the activated cult...

Embodiment 3

[0036] A kind of method utilizing soy sauce filter residue to prepare D-glucosylceramide, adopts following steps:

[0037] A. Use an inoculation loop to measure 15 strains of Sphingomonas sp., preservation number CICC10694, and 15 strains of Yarrowia lipolytica (Yarrowia lipolytica), preservation number CICC 1441; Inoculate into 100 mL activation medium respectively, the activation medium is composed of 0.50% peptone by mass ratio, 0.60% NaCl, 5% sucrose, and the remaining distilled water; and cultivated in a constant temperature incubator for 72 h at a temperature of 26 ℃, control the pH to 7.2; respectively obtain Sphingomonas (Sphingomonas sp.) strain activated culture solution P and Yarrowia lipolytica (Yarrowia lipolytica) (Sphingomonas sp.) The concentration of the bacterial solution in the activated culture solution P of the strain is 7×105 CFU / mL, and the concentration of the bacterial solution in the activated culture solution Q of the Yarrowia lipolytica strain is 7×...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com