A high temperature slag granulation system

A slag granulation, high temperature technology, applied in recycling technology and other directions, can solve the problems of difficulty in achieving granulation sustainability, long time consuming for granulation system cleaning, and difficulty in coordinating wind speed and air volume to achieve granulation effect. Ideal, improved granulation efficiency, and guaranteed continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0029] In this embodiment, a high-temperature slag granulation system can receive high-temperature slag and perform granulation treatment on the slag, and the processed slag can be used for secondary use.

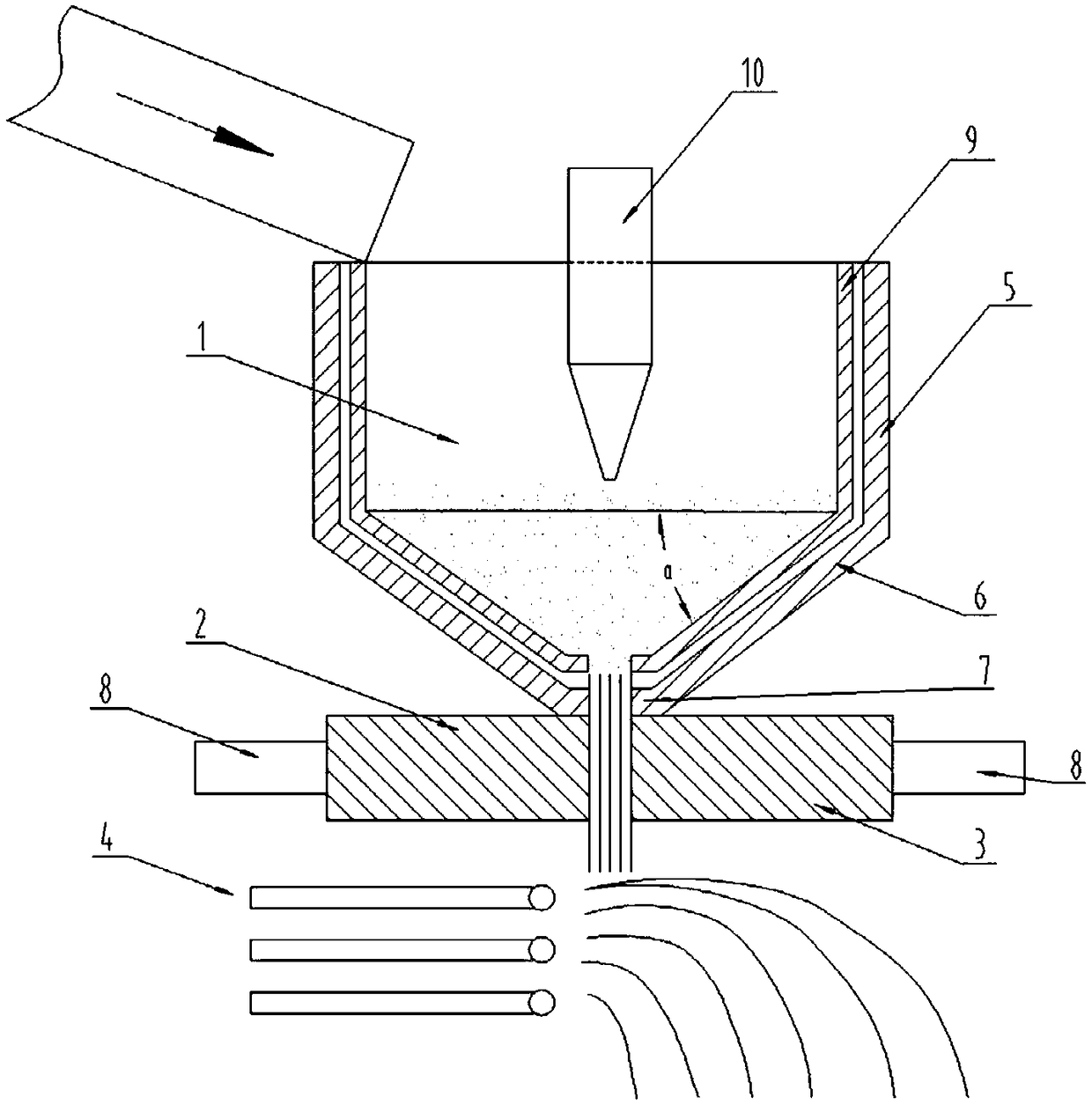

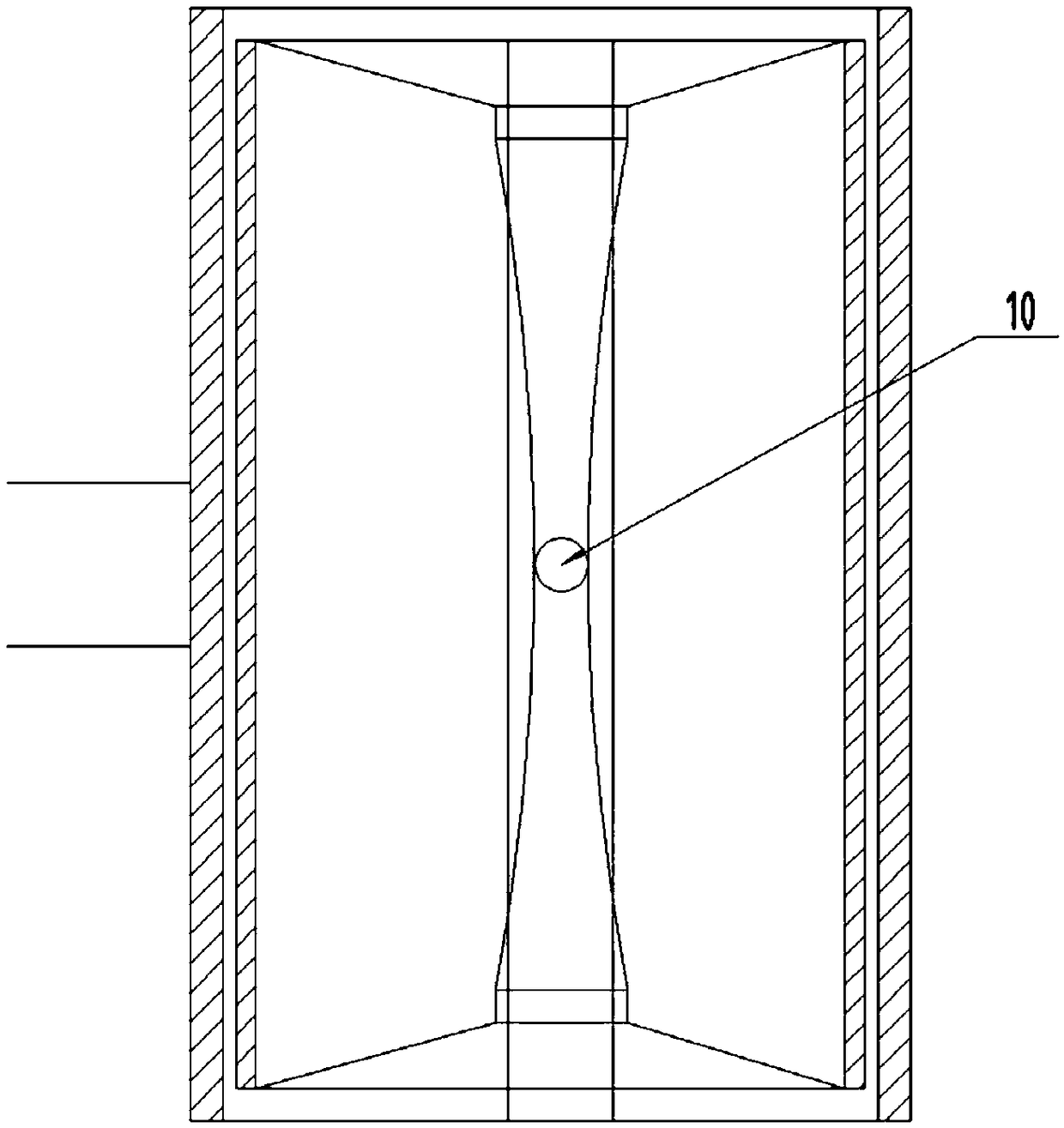

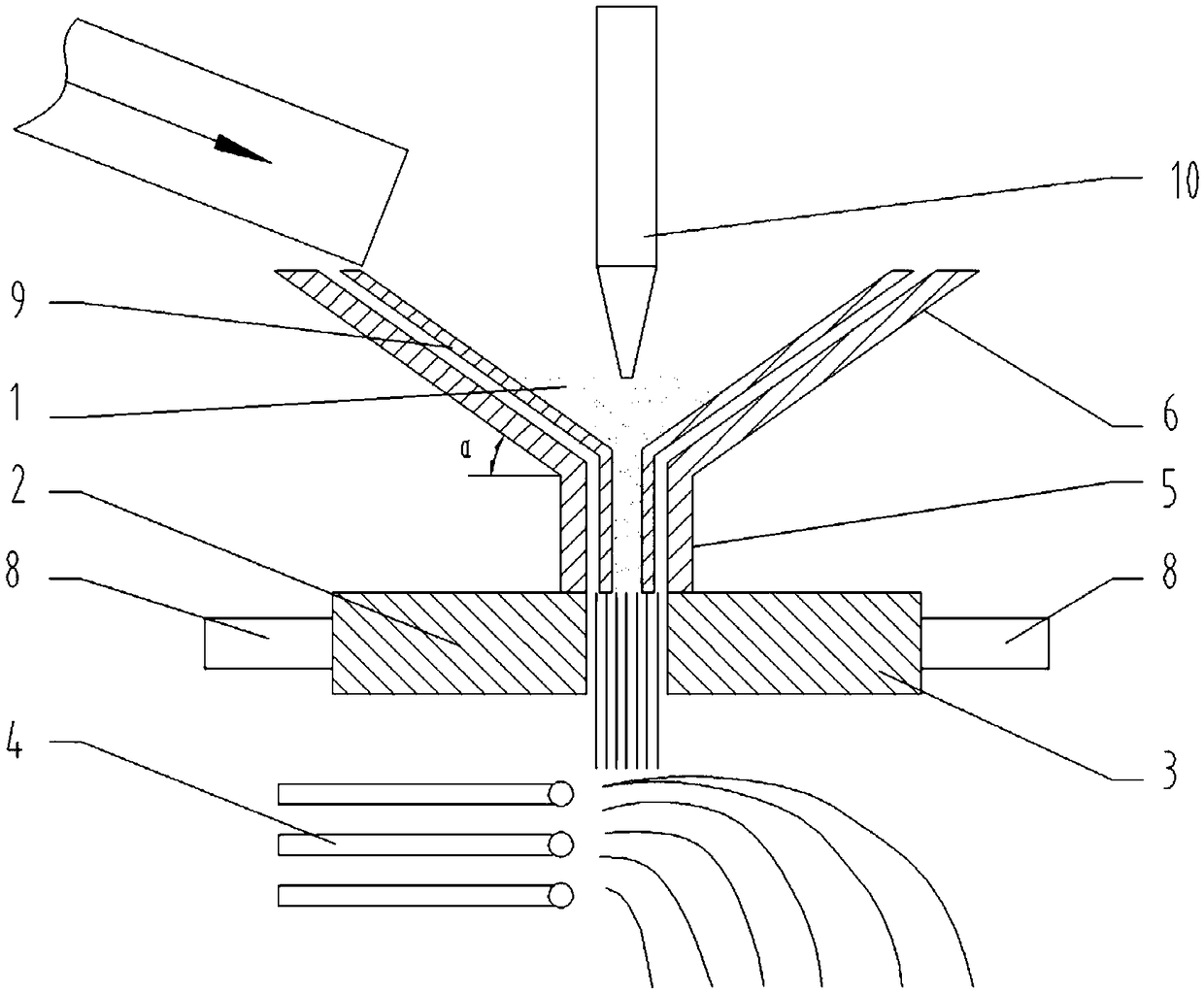

[0030] Such as figure 1 As shown, the granulation system includes a slag tank 1 , a first regulating brick 2 , a second regulating brick 3 , and a granulating device 4 .

[0031] The slag trough 1 includes a slag trough straight section 5 and a slag trough inclined section 6. The slag trough straight section 5 is vertically fixedly connected to the top of the slag trough inclined section 6. In order to slow down the impact velocity of incoming slag, a The horizontal straight section 7 of the slag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com