Multi-functional paper-plastic cleaning separation and pulp quenching equipment

A multi-functional, paper-plastic technology, applied in raw material separation, papermaking, paper recycling, etc., can solve the problems of not being able to observe the working conditions of the rectangular buffer cover, external operators being unable to find faults in time, and delaying the timing of emergency shutdown, etc., to achieve Avoid inflexible or stuck rotation, compact structure, and meet the effect of shielding protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0038] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

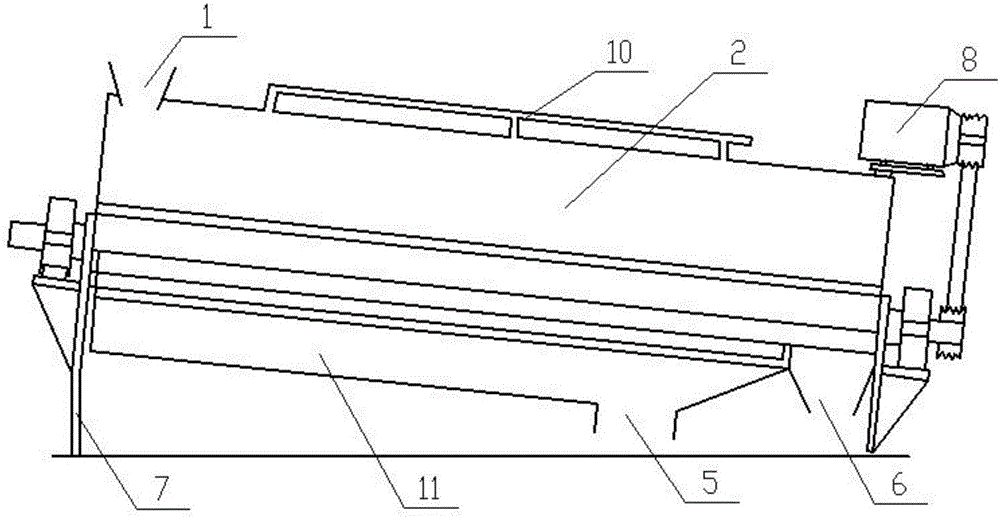

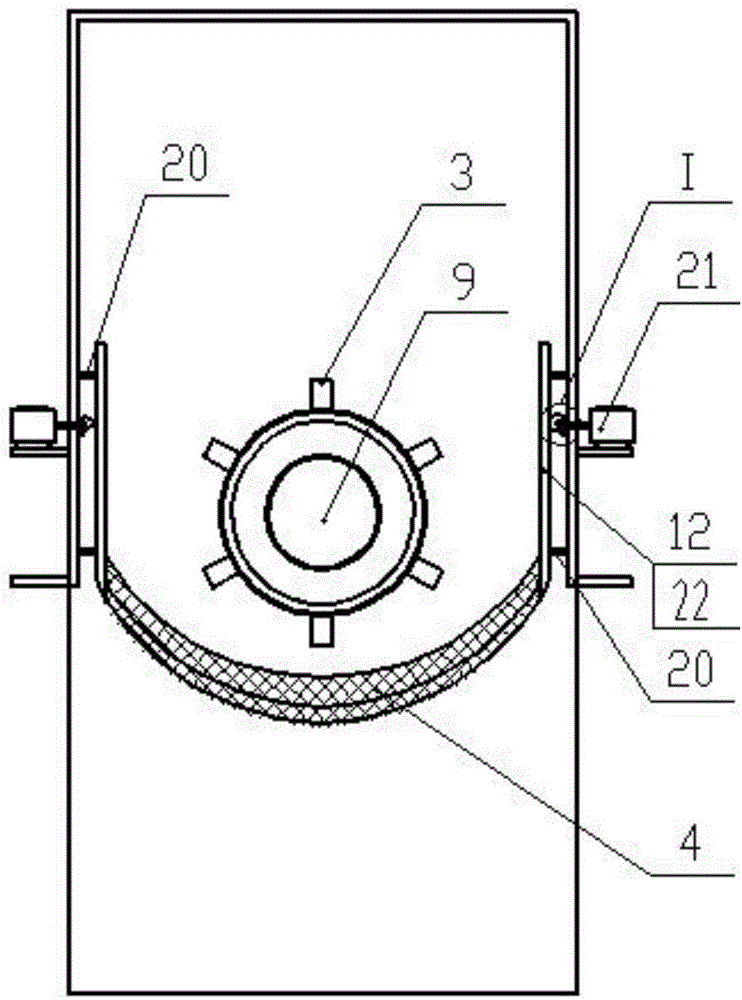

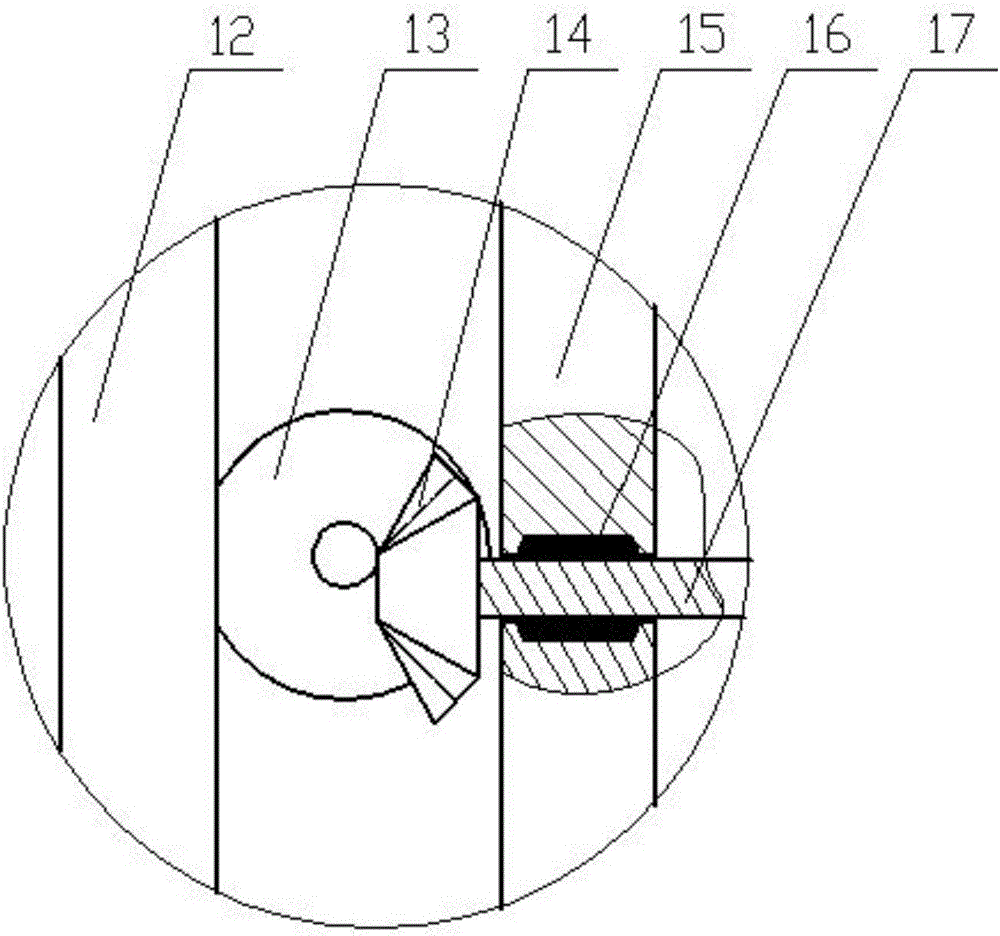

[0039] like figure 1 As shown in -5, a multi-functional paper-plastic cleaning, separating and quenching equipment is composed of a rectangular buffer cover 2 and a semicircular screen 4. The rectangular buffer cover 2 is made into a rectangle, which can prevent excessive feeding and have a buffer space to prevent the spindle 9 stuck. Main shaft 9 runs straight through the machine barrel, and the motor is installed above the rectangular buffer cover 2, and the 9 rotating speeds of the main shaft are regulated with belt pulleys. The friction strip 3 is in the same direction as the main shaft 9, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com