Prestressed bridge surface connection device and prefabrication method and construction method thereof

A connecting device and prestressing technology, which is applied in the direction of bridges, bridge parts, bridge materials, etc., can solve problems such as cracking, crushing and sags, and achieve the effects of improving durability, solving easy damage, and driving smoothly and comfortably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

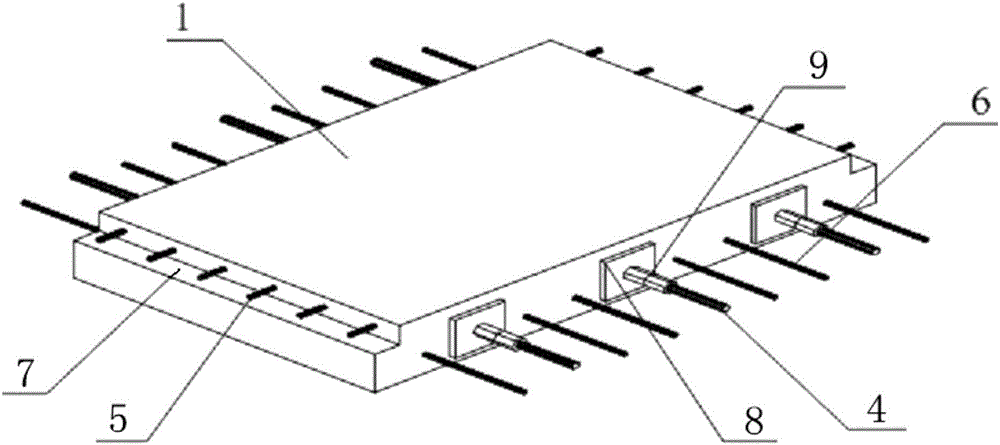

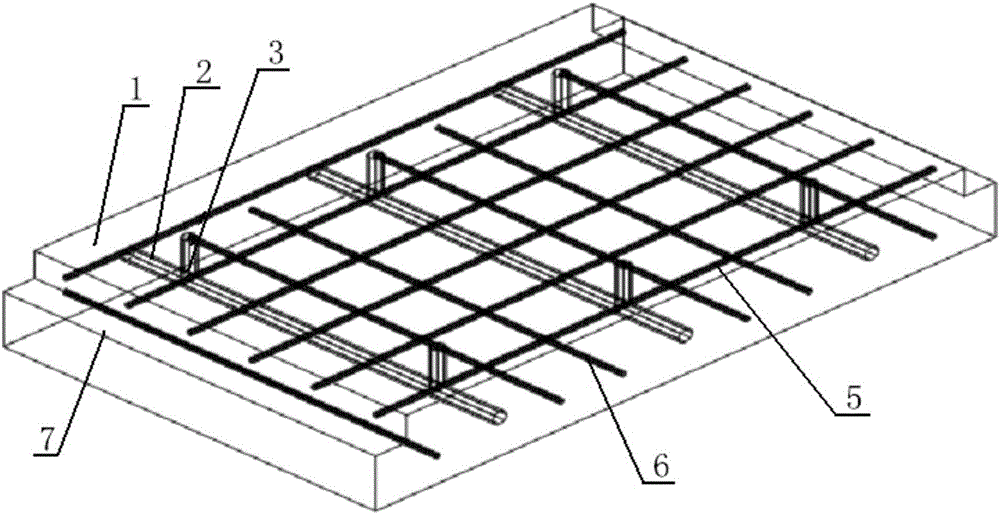

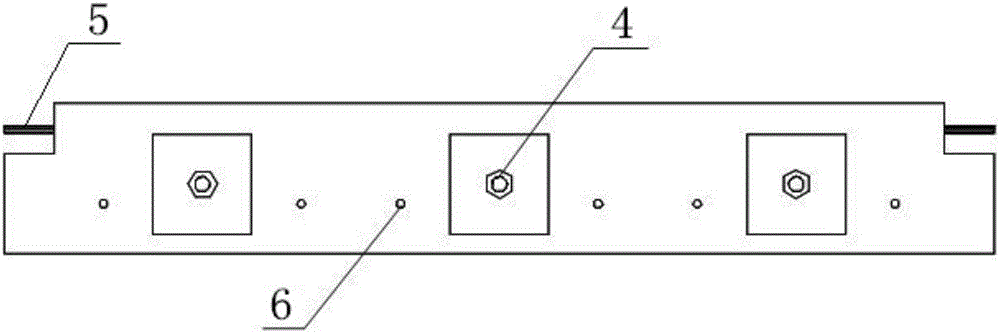

[0036] Such as Figure 1-Figure 7 As shown, a prestressed bridge deck connection device includes a connecting plate main body 1 poured with ultra-high performance concrete materials. Three parallel corrugated pipes 2 are fixed longitudinally inside the main body 1 of the connecting plate, and two through grouting holes 3 are arranged above the pipe wall of each corrugated pipe 2, and the grouting holes 3 communicate with the inside of the bellows 2 in the connecting plate main body 1 Channels are formed inside and closed after grouting. The bellows 2 is inserted with a prestressed steel bar 4 stretched by "post-tensioning" that can increase the prestress of the connecting plate main body 1. The length of the prestressed steel bar 4 is greater than the length of the bellows 2. The prestressed steel bar 4 and the corrugated There is a clearance fit between the pipes 2, and a fixing assembly for fixing the prestressed steel bar 4 to prevent retraction is provided between the two...

Embodiment 2

[0046] A prestressed bridge deck connection device of the present invention is prefabricated according to the following steps:

[0047] ① Preparation of concrete slurry;

[0048] In this example, in order to prepare ultra-high performance concrete slurry: add cement and silica fume into a dry mixer in proportion, start it up and stir for 2 minutes, then stop it, add fine quartz sand and stir for 1 minute, and then add a certain amount of water Mix with water reducer and keep stirring, stir for 4 minutes until uniform to obtain slurry, add a certain amount of steel fiber in stages and stir until the steel fiber is well wrapped and evenly distributed by the slurry, and ultra-high performance concrete slurry is obtained material. The resulting ultra-high performance concrete (UHPC) slurry is a cement-based material with ultra-high strength, high toughness and durability.

[0049] ②Pouring: The formwork of the prestressed bridge deck connection device is made in advance. The for...

Embodiment 3

[0062] Such as Figure 5-Figure 7 As shown, a kind of prestressed bridge deck connecting device of the present invention carries out on-site construction at the bridge construction site according to the following steps:

[0063] ①Pay the debonding layer 17 at the end of the main beam 15, that is, brush two layers of asphalt above the end of the precast concrete beam, and then spread a layer of plastic film, and use light material 18 to fill the space between the main beam 15, such as light Packaging board or bitumen impregnated cork board.

[0064] ②Assembly: Assemble the bridge deck connection device in a modular manner. The main body 1 of the horizontal connecting plate is connected with the horizontal connecting steel bar 5, and the longitudinal connecting steel bar 6 is used to connect the bridge deck steel mesh 16 on both sides vertically.

[0065] ③ Set waterproof material at 7 post-pouring belts at both ends of the bridge deck connection device, and use concrete above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Longitudinal length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com