Assembled concrete filled steel tubular column splicing structure and method

A technology for concrete-filled steel pipe columns and concrete columns, which is applied in the direction of columns, pier columns, pillars, etc., and can solve the problems of non-compliance with applicable, economical, green, and beautiful architectural guidelines, low recycling rate of building materials, and high material and energy consumption. , to achieve superior energy dissipation capacity and ductility of the overall structure, reduce on-site welding work and template work, and achieve low repair and replacement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

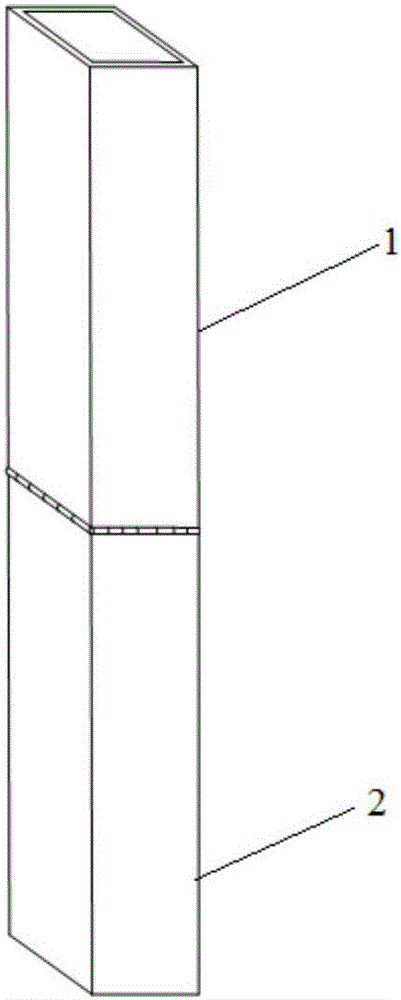

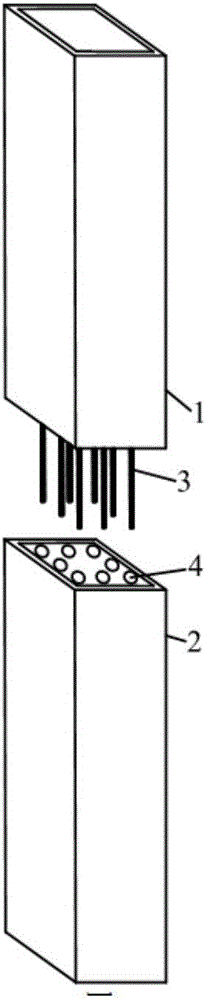

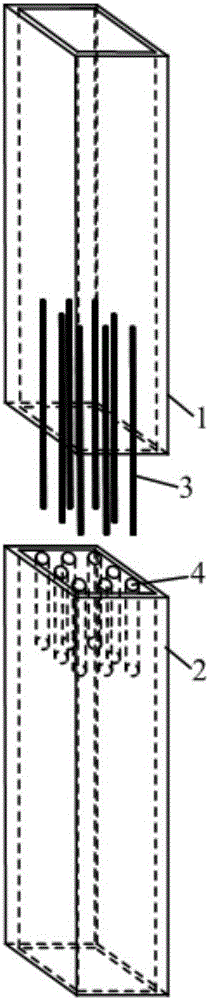

[0029] See Figure 1 to Figure 4 As shown, a splicing structure of prefabricated concrete-filled steel tube columns and columns, including two concrete-filled steel tube columns arranged one above the other. A number of steel bars 3 are pre-embedded in the upper concrete-filled steel pipe column 1, and part of the steel bars 3 extends downward out of the bottom surface of the upper concrete-filled steel pipe column 1; a number of corrugated sleeves 4 are embedded in the lower steel-filled steel tube concrete column 2, and one end of the corrugated sleeve 4 is exposed to the The top surface of the lower concrete filled steel pipe column 2. Concrete slurry is injected into the corrugated casing 4 and the steel bars 3 are connected to the corrugated casing 4 one by one, so that the bottom surface of the upper concrete-filled steel tube column 1 is connected to the top surface of the lower steel-filled steel tube concrete column 2. Realize the splicing of two steel pipe concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com