Wind-gathering pressurized maglev vertical wind power generation system

A wind power generation system and wind collection technology, applied in the field of vertical wind power generation system, wind collection pressurized maglev vertical wind power generation system, can solve the problem of small working wind area, easy to be destroyed by storm, large impact on power grid, etc. problems, to achieve the effect of maintaining continuity and stability, increasing power generation capacity and utilization efficiency of wind resources, and increasing wind drive torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

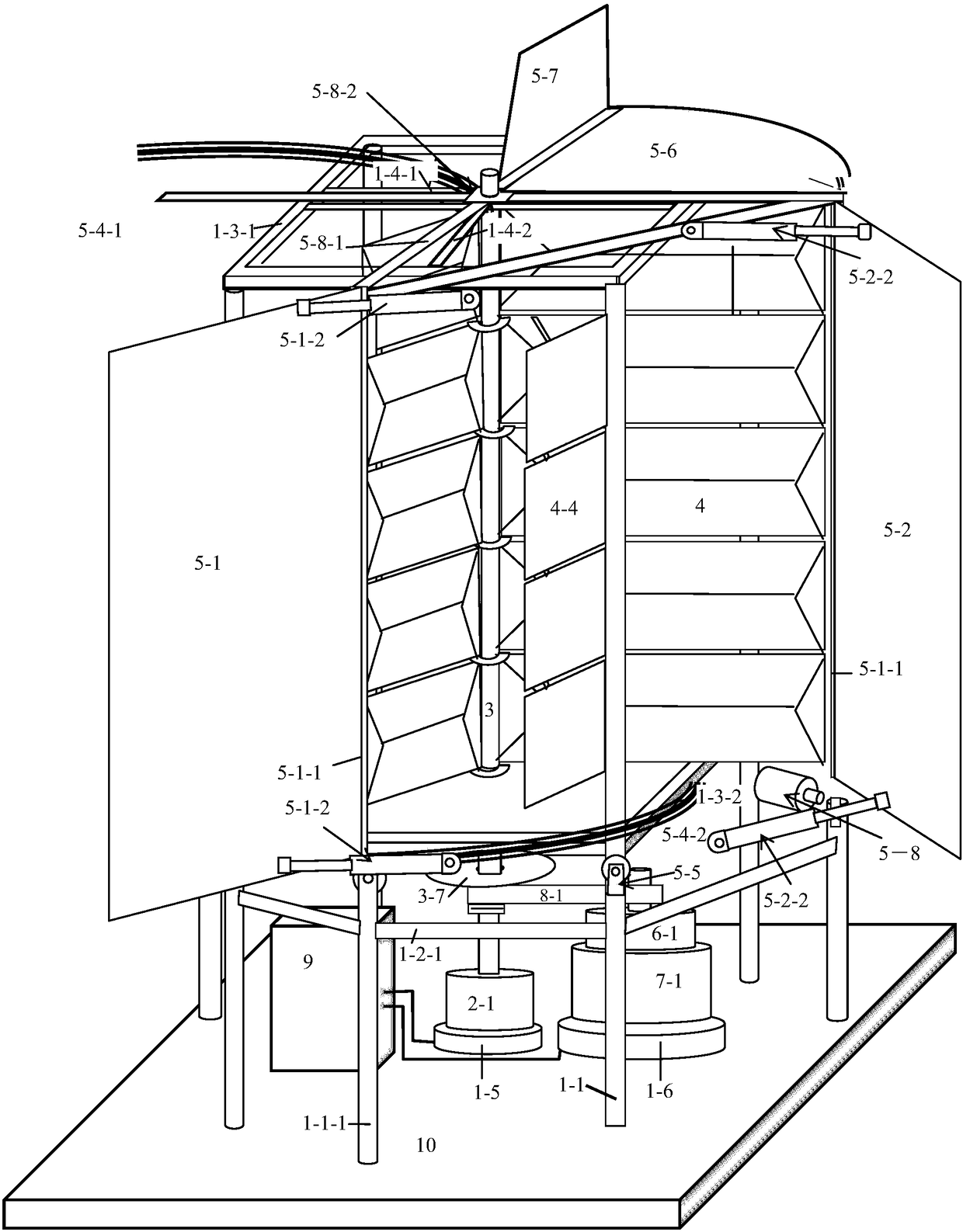

[0114] In this embodiment: the main body of the system frame is composed of the frame column 1-1, the lower beam 1-2 and the upper beam 1-2, Figure 9 and Figure 12 The lower track 5-4-2 of the air collection and booster system shown is installed outside the four columns 1-1 of the system frame Figure 12 The support piece and the auxiliary support column 1-1-1.

[0115] Figure 14 The schematic diagram of the structure of the supporting member 5-5 is shown. 5-5 in the figure is fixed on the fixed column 1-1, 5-5-1 is the supporting shaft, 5-5-2 is the pulley, and the lower track 5-4-2 is installed on the pulley, and the rudder plate 5 of the wind collecting system -7 It is estimated that the steering drive device 5-9 drives the rack mounted on the lower track 5-4-2 5-4-3 to estimate that the wind collection system 5 follows the wind direction and rotates, so that the wind collection booster protection system can track the wind direction Rotate under control system 9 cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com