Water pump total-lift work control method, controller and water pump

A work control and controller technology, which is applied in pump control, non-variable pumps, machines/engines, etc., can solve the problems of increasing production costs, affecting the service life of water pumps, and reducing the service life of water pumps, so as to avoid the waste of electric energy , Improve the degree of intelligence, and stabilize the water supply pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

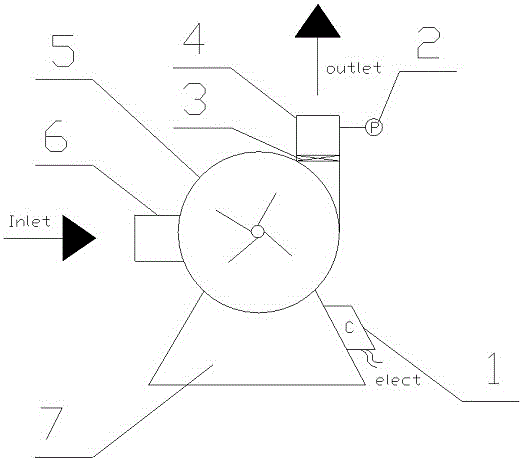

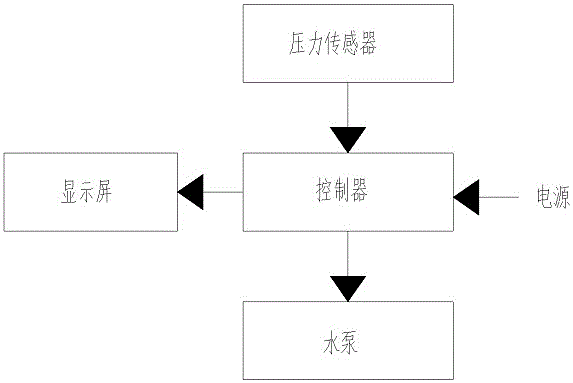

[0045] combine figure 1 and figure 2 A water pump shown includes a pump body 5, a water inlet 6, a water outlet 4, a base 7, a controller 1, a pressure sensor 2 and a check valve 3; wherein the water inlet 6 is the low pressure end of the water pump , the water outlet 4 is the high pressure end of the water pump, the water outlet 4 and the water inlet 6 are connected to the pump body; the pressure sensor 2 is used to detect the outlet pressure of the water pump, and output a pressure signal to the controller 1; The controller 1 is used to connect the external power supply and control the start and stop of the water pump; the check valve 3 is arranged at the water outlet 4 and upstream of the pressure sensor 2 .

Embodiment 2

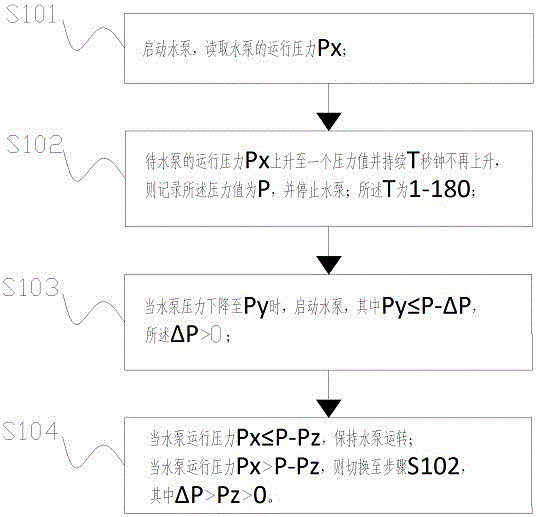

[0047] Such as image 3 and Figure 4 As shown, the water pump full lift work control method described in the above-mentioned embodiment 1 includes the following steps,

[0048] S101, start the water pump, and read the operating pressure P of the water pump x ;

[0049] S102, the operating pressure of the pump to be pumped P x Rise to a pressure value and continue for T seconds and no longer rise, then record the pressure value P, and stop the water pump; the T is 1-180;

[0050] S103, when the water pump pressure drops to P y When the water pump is started, where P y ≤P-ΔP, said ΔP>0;

[0051] S104, when the pump operating pressure P x ≤P-P z , to keep the water pump running; when the water pump running pressure P x >P-P z , then switch to step S102, where ΔP>P z >0.

[0052] Further, the P y It is pre-set; it can be set by the manufacturer when the water pump leaves the factory, or by the user when using the water pump according to the water supply demand.

[0...

Embodiment 3

[0063] combine Figure 7 The shown controller is a control circuit board that can realize any one of the water pump full-lift work control methods described in Embodiment 2 to control the water pump; the control circuit board includes:

[0064] The single-chip microcomputer 11 is used to store data and execute software programs, receive pressure signals and output signals;

[0065] The relay 31 is used to control the power on and off of the water pump and is connected to the drive module 21;

[0066] The drive module 21 is connected with the single chip microcomputer 11, and is used to control the switch of the relay 31;

[0067] The display screen 41 is connected with the single-chip microcomputer 11 for displaying pressure and fault codes;

[0068] The circuit module 51 is used for powering the single chip microcomputer 11 and the relay 31 .

[0069] The above-mentioned controller can be set on the outlet pipeline of the water pump to be controlled in conjunction with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com